Heat treatment method of iron-based wear-resistant coating plough shovel tip

A heat treatment method and wear-resistant coating technology, applied in heat treatment furnaces, heat treatment equipment, coatings, etc., can solve the problems of reduced performance, cracking of wear-resistant layers, low work efficiency, etc., to achieve low production costs and eliminate quenching stress. , to avoid the effect of quenching secondary cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

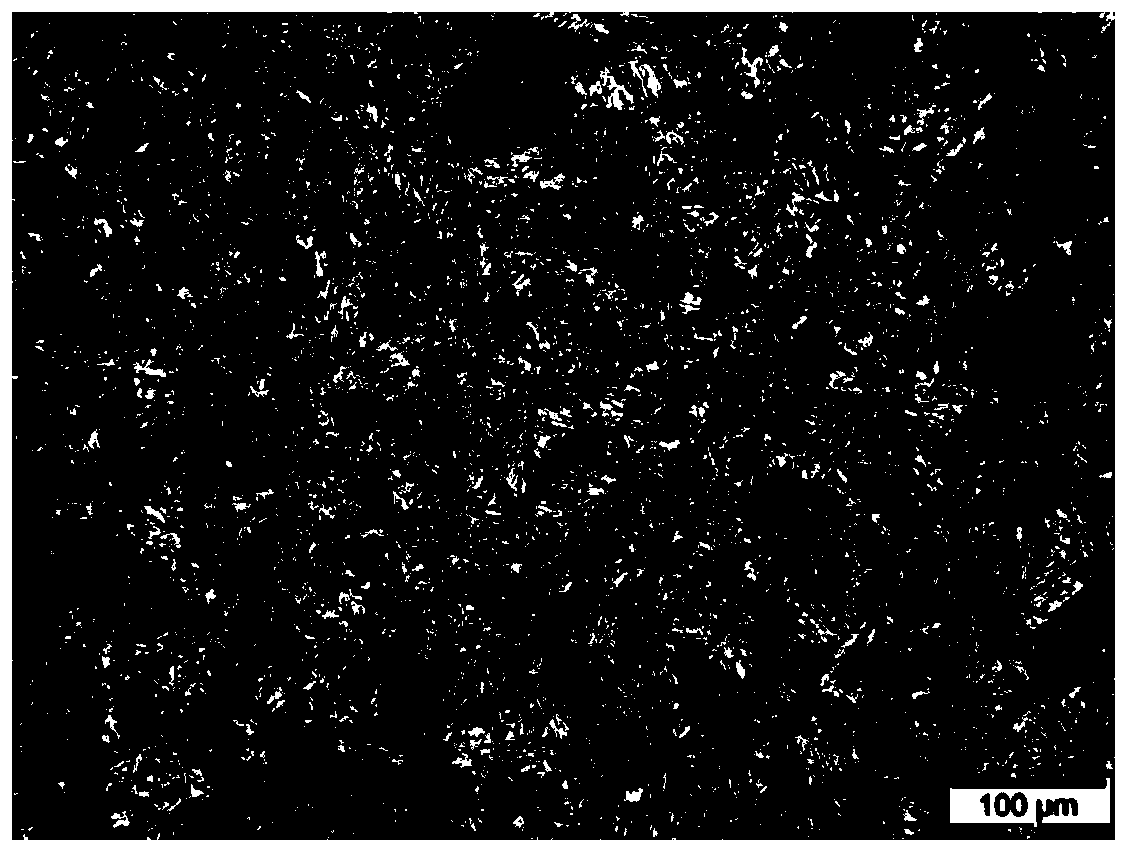

[0037] In Example 7, the matrix structure of the plow and shovel tip sample after quenching in a 300°C salt bath is martensite + upper bainite, and the impact toughness index is extremely low, which cannot meet the product use requirements;

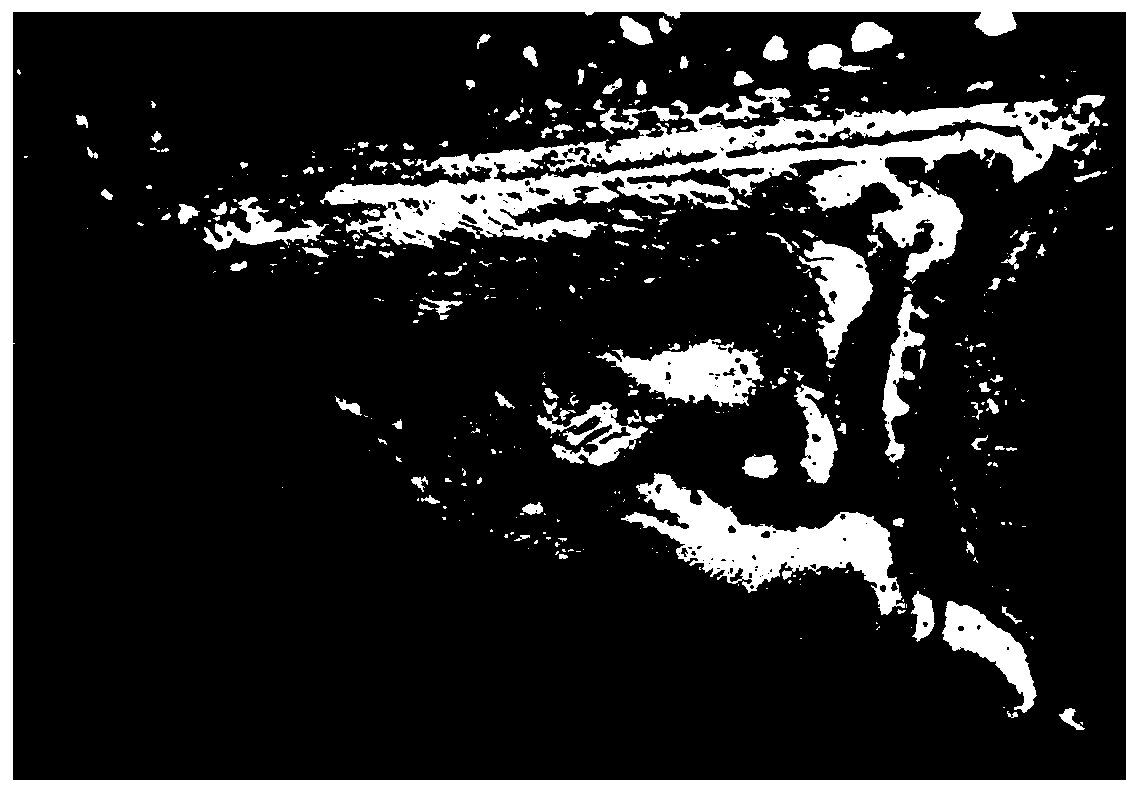

[0038] Embodiments 4, 5, and 6 not only ensure the appearance quality of the plow and shovel tip sample, but also enable it to obtain higher strength and toughness.

[0039] The present invention has carried out a large number of tests to verify under different quenching and holding temperatures, times and quenching conditions, and the test results and rules are consistent with the above-mentioned embodiments.

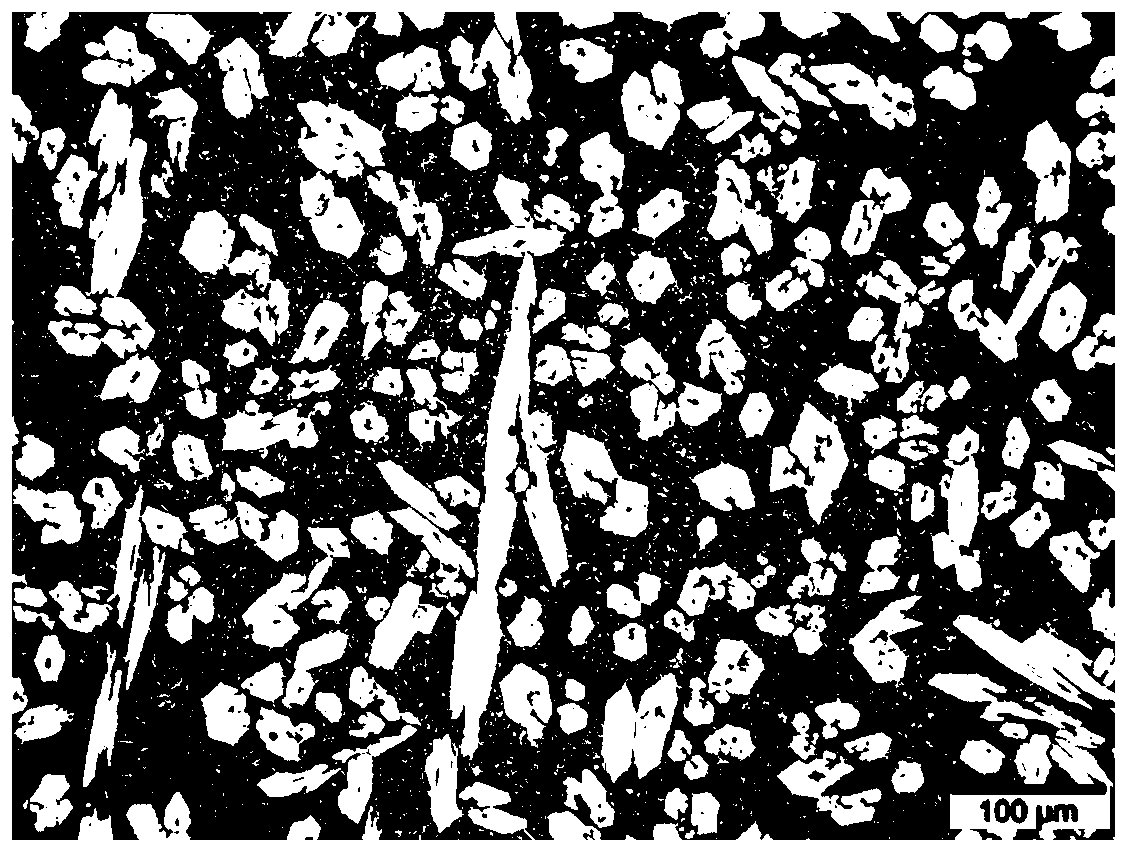

[0040] Such as figure 1 As shown, the metallographic structure diagram of the iron-based wear-resistant layer sprayed and welded according to the test composition, it can be seen from the figure that the metallographic structure of the wear-resistant coating is composed of a martensite matrix and a uniformly distributed hard point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com