Lamination-based vacuum brazing method for core part of plate-fin type aluminum heat exchanger

A brazing method and heat exchanger technology, which is applied in the field of aluminum alloy welding, can solve the problems of time-consuming and other problems, and achieve the effects of reducing production costs, strong operability and controllability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

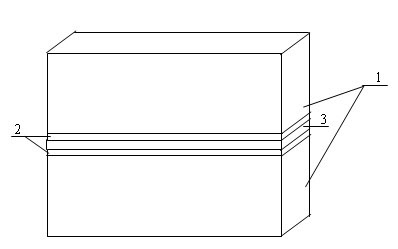

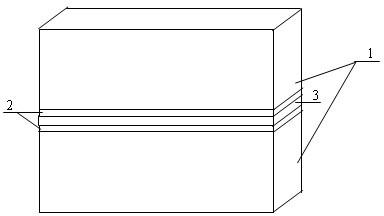

Image

Examples

Embodiment 1

[0027] The core size of a heat exchanger with two heat exchange channels is (length×width×height): 427×190×102mm, the side plate size is 427×190mm, and 4004 brazing filler metal with a thickness of 0.1mm is used as the heat exchanger core The brazing material for brazing between the upper side plate and the fins and seals is to use 3003 aluminum alloy plate with a thickness of 6mm and R-5461-S mica tape with a thickness of 0.15mm as the isolation layer between adjacent heat exchanger cores Materials, 12 heat exchanger cores are stacked and assembled, and after the assembly inspection is passed, they are sent to a vacuum brazing furnace for brazing, and the brazing chamber is evacuated to 7×10 -4 At Pa, start to heat up to 200°C and 540°C at a heating rate of 10°C / min for 20 minutes respectively, then raise the temperature to 605°C at a heating rate of 4°C / min and hold for 5 minutes, then stop heating until the brazing chamber cools down to 360°C Close the vacuum system at ℃, o...

Embodiment 2

[0029]The core size of a heat exchanger with two heat exchange channels is (length×width×height): 470×210×327mm, the side plate size is 470×210 mm, and a 4004 brazing sheet with a thickness of 0.1mm is used as the heat exchanger The brazing material used for brazing between the core side plates, fins and seals is 3003 aluminum alloy plate with a thickness of 6mm and R-5461-S mica tape with a thickness of 0.15mm as the insulation between adjacent heat exchanger cores Layer materials, 4 heat exchanger cores are stacked and assembled, and after the assembly inspection is passed, they are sent to a vacuum brazing furnace for brazing, and the brazing chamber is evacuated to 8×10 -4 At Pa, start to heat up to 200°C and 540°C at a rate of 9°C / min and hold for 15 minutes each, then raise the temperature to 605°C at a rate of 3°C / min and hold for 5 minutes, then stop heating until the temperature of the brazing chamber cools down to 350°C Turn off the vacuum system at the same time, op...

Embodiment 3

[0031] The core size of a heat exchanger with two heat exchange channels is (length×width×height): 400×200×491mm, the side plate size is 400×200 mm, and a 4004 brazing sheet with a thickness of 0.1mm is used as the heat exchanger The brazing material for brazing between the core side plate and the fins and seals is to use a pure aluminum plate with a thickness of 6 mm and a R-5461-S mica tape with a thickness of 0.15 mm as the isolation layer between adjacent heat exchanger cores Materials, 3 heat exchanger cores are laminated and assembled, and after the assembly inspection is passed, they are sent to a vacuum brazing furnace for brazing, and the brazing chamber is vacuumed to 8×10 -4 At Pa, start to heat up to 200°C and 540°C at a heating rate of 8°C / min and keep warm for 20 minutes, then raise the temperature to 605°C at a heating rate of 3°C / min and hold for 4 minutes, then stop heating, and wait for the brazing chamber to cool down to 350°C Turn off the vacuum system at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com