A kind of nickel base flux core solder, preparation method and application

A flux-cored and nickel-based technology is applied in the field of nickel-based flux-cored brazing filler metals, and can solve the problems of low brazing efficiency, low brazing joint strength, and poor processability of nickel-based brazing filler metals. Improve the brazing efficiency and the effect of automatic and precise addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

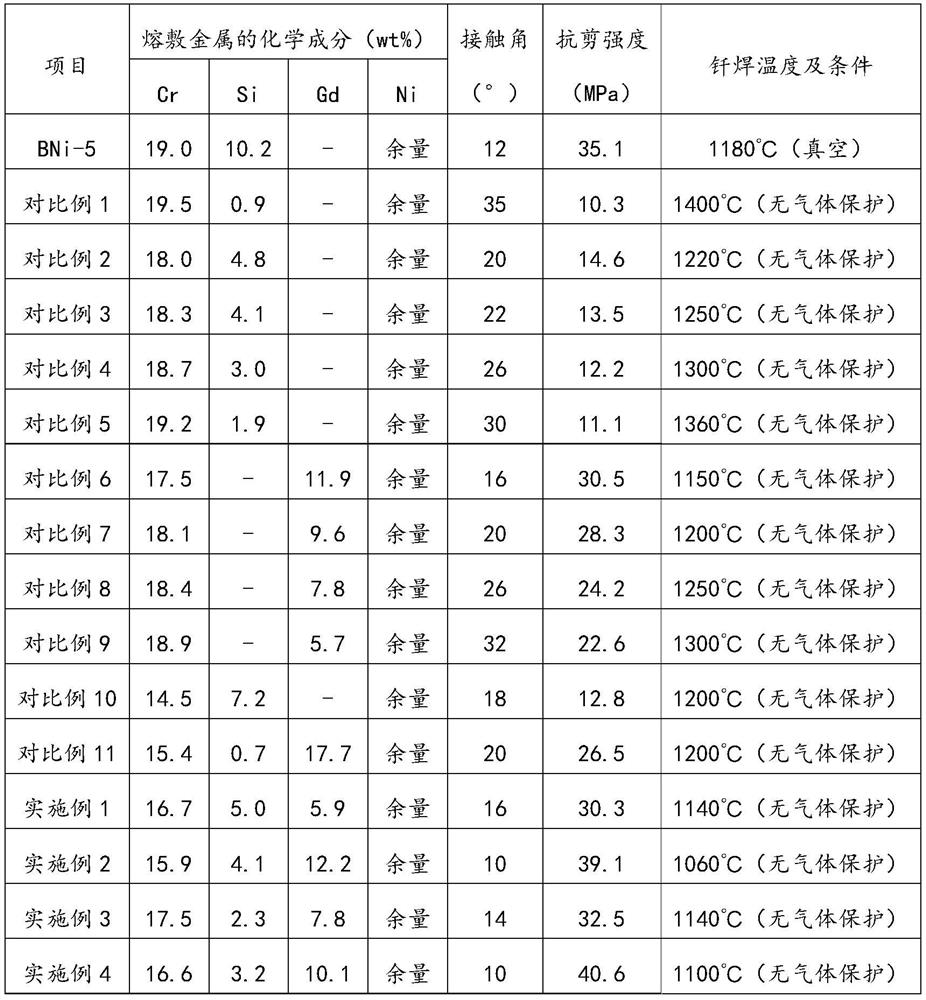

Examples

Embodiment 1

[0034] The present embodiment discloses a nickel-based flux-cored solder, comprising a flux core and a nickel-based alloy surrounding the flux core;

[0035] The nickel-based alloy is a nickel-chromium alloy;

[0036] Described drug core includes according to mass fraction:

[0037] NiSi 2 Powder 24%, GdF 3 Powder 19%, brazing flux powder 57%;

[0038] The brazing flux powder includes boric acid and borax, wherein the mass ratio of boric acid and borax is 3:1.

[0039] The flux core accounts for 35% of the total mass of the nickel-based flux cored solder.

[0040] The nickel-chromium alloy strip used in the present invention has a width of 15 mm and a thickness of 0.6 mm, and includes: Cr20% and Ni80% according to the mass fraction.

[0041] The preparation method of nickel-based flux-cored solder in this embodiment includes the following steps:

[0042] Step 1, selection and preparation of raw materials: take the nickel-chromium alloy strip, prepare the quality of each ...

Embodiment 2

[0046] The main difference between this embodiment and Embodiment 1 is:

[0047] The chemical composition of the core and its mass percentage are: NiSi 2 Powder 17%, GdF 3 33% of the powder, 50% of the brazing flux powder; the flux core accounts for 40% of the total mass of the nickel-based flux cored solder.

Embodiment 3

[0049] The main difference between this embodiment and Embodiment 1 is:

[0050]The chemical composition of the core and its mass percentage are: NiSi 2 Powder 13%, GdF 3 The powder is 30%, and the brazing flux powder is 57%; the flux core accounts for 30% of the total mass of the nickel-based flux core brazing filler metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com