Brazing method of wear-resistant sheet

A brazing method and technology of wear-resistant sheets, which are applied in the brazing of wear-resistant sheets and substrates, and in the field of brazing wear-resistant sheets, can solve problems such as waste of hard alloys, high scrap rate, and low production efficiency, and achieve brazing High welding efficiency and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

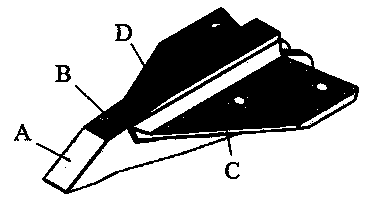

[0017] attached figure 1 It is the product schematic diagram of subsoiling shovel I, brazing wear-resistant sheets on the two slopes A and B of its head, and welding wear-resistant sheets on the C and D surfaces of its flanks. When brazing the wear-resistant sheet on the slope B, place the surface B horizontally, and the traditional brazing process can be used to complete the welding of the wear-resistant sheet. When brazing the wear-resistant sheet on the other slope A, place surface A horizontally at this time, and the surface B is an inclined surface. During the heating process of the wear-resistant sheet on the brazing surface A, it is easy to make the wear-resistant sheet that has been brazed on the B surface The brazing material melts and flows along the inclined surface, making the brazing of the wear-resistant sheet on the B side invalid.

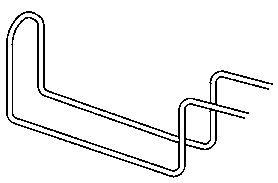

[0018] This embodiment uses high-frequency induction rapid surface heating, using image 3 The single-turn induction coil shown,...

Embodiment 2

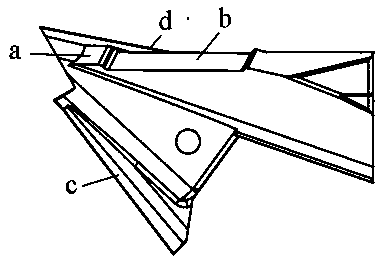

[0029] attached figure 2 It is the product schematic diagram of the subsoiler shovel II. The welding position of the wear-resistant plate of the subsoiler shovel II is basically the same as that of the subsoiler shovel I. The tooling used is different, and the induction heating parameters are basically the same as the brazing process.

[0030] Two kinds of subsoiling shovels are supplied in small batches, the mechanical properties and service life meet the requirements, the brazing performance of the products is reliable, and no bad feedback has been received from users such as peeling off, cracks, and non-wearing of wear-resistant sheets, and they are rated as high-quality suppliers by customers. .

[0031] The wear-resistant sheet brazing method has a simple process, low requirements on operator skills, good brazing quality, and can meet the needs of mass industrial production, and the automatic production of wear-resistant sheet brazing can be realized after the introduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com