A multi-element heating method for a vacuum diffusion brazing furnace

A technology of vacuum diffusion and heating method, used in electric heating devices, welding equipment, metal processing equipment, etc., can solve the problem that high temperature, large workpiece heating needs, the heat required for heating can only be achieved by thermal radiation, and the workpiece heating range is small, etc. problems, to achieve the effect of scientific heating method, shorten heating time, and improve brazing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

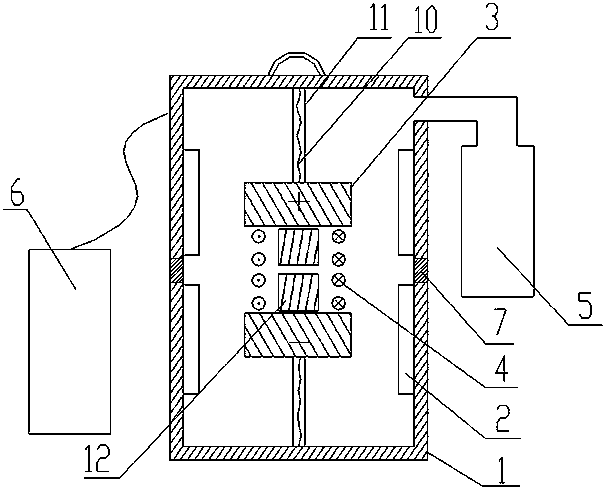

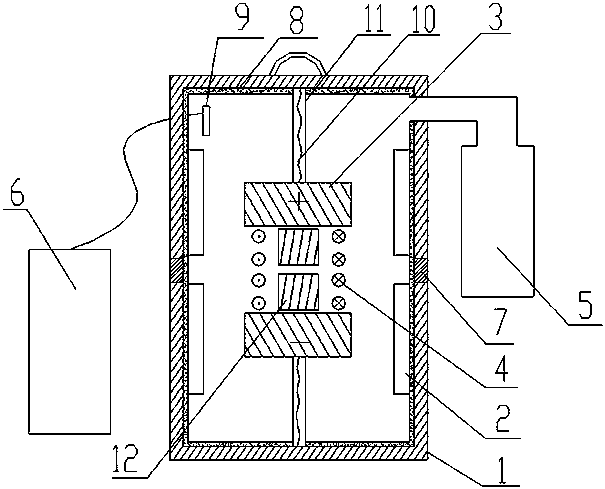

[0056] refer to Figure 1~3 , a vacuum diffusion brazing furnace, comprising a furnace body 1, a heating element 2, a resistance electrode 3 and an induction coil 4 are arranged in the furnace body, the inside of the furnace body is connected with a vacuum pump 5, a workpiece 13 is placed between the resistance electrodes, and the induction coil surrounds the The workpiece is set, the heating element is arranged on the inner wall of the furnace body, the heating element, the resistance electrode and the induction coil are respectively connected to the controller 6 and the power supply in sequence, and the furnace body is sealed by an insulating sealing ring 7 . Among them, the heating element in the furnace body is a high-temperature molybdenum alloy, and the high-temperature molybdenum alloy is 1# in Table 1. The heating element is spirally arranged on the inner wall of the furnace body. The resistance electrode is connected to the low-voltage power supply through an anneale...

Embodiment 2

[0061] refer to Figure 1~3 , The structure of the vacuum diffusion brazing furnace described in this embodiment is different from Embodiment 1 in that: the heating element in the furnace body is a high-temperature molybdenum alloy, and the high-temperature molybdenum alloy is 2# in Table 1.

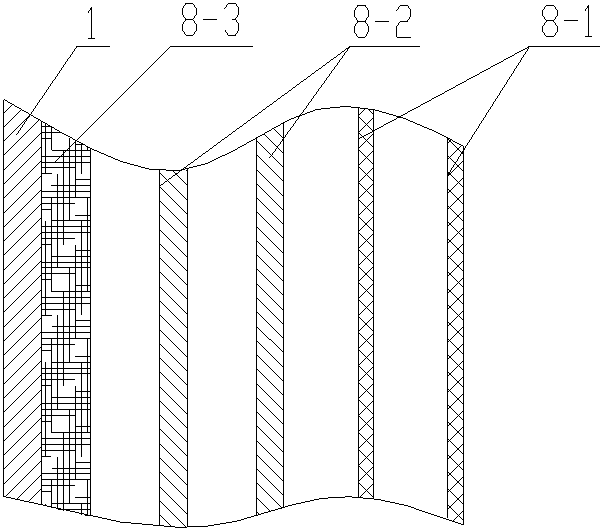

[0062] Radiation screen 8 is arranged inside the furnace body, and the radiation screen is 2 layers of molybdenum screen 8-1 with a thickness of 0.4 mm, 2 layers of heat-resistant steel screen 8-2 with a thickness of 0.7 mm and 1 layer with a thickness of The stainless steel screen 8-3 is 1.5 mm, and the layer spacing is 2.5 mm.

[0063] Refer to Example 1 for the multi-element heating method of the vacuum diffusion brazing furnace in this embodiment.

Embodiment 3

[0065] refer to Figure 1~3 , The structure of the vacuum diffusion brazing furnace described in this embodiment is different from Embodiment 1 in that: the heating element in the furnace body is a high-temperature molybdenum alloy, and the high-temperature molybdenum alloy is 3# in Table 1.

[0066] Radiation screen 8 is arranged inside the furnace body, and the radiation screen is 2 layers of molybdenum screen 8-1 with a thickness of 0.4 mm, 2 layers of heat-resistant steel screen 8-2 with a thickness of 0.7 mm and 1 layer with a thickness of The stainless steel screen 8-3 is 1.5 mm, and the layer spacing is 2 mm.

[0067] The multiple heating method of the vacuum diffusion brazing furnace described in this embodiment comprises the following steps:

[0068] Step S1: Set the workpiece between the resistance electrodes and in the induction coil; connect the vacuum pump to the furnace body, use the vacuum pump to evacuate the furnace body, and when the furnace body reaches the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com