Cored copper welding wire suitable for small area brazing

A brazing wire and cored technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve problems such as unsuitable for high-efficiency brazing, and achieve convenient and reliable welder operation, high brazing efficiency, and easy absorption hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

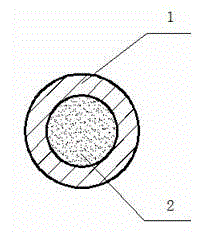

[0033] Such as figure 1 As shown, the diameter of the seamless welding wire is 2.0mm, which is divided into the outer layer homogeneous alloy solder 1 and the inner core solder 2 structurally, the inner core diameter is 1.0mm, and the weight ratio of the outer layer homogeneous alloy solder is 88%. The weight ratio of the inner core flux is 12%. The composition of the outer homogeneous alloy solder is 59% Cu, 38% Zn, 1.5% Sn, 0.8% Mn, 0.5% Ni and 0.2% Si; the inner core composition is 70% B 2 o 3 , 21% Na 2 O·2B2 o 3 , 4% CsF and 5% NaF. The butt weld of aluminum bronze rod (QAl9-4) with a diameter of 3mm is used for flame brazing, which can be directly brazed to form, without turbulent flow of brazing material, full brazing seam shape, reliable quality, and the tensile strength of the connection can reach 290MPa.

Embodiment 2

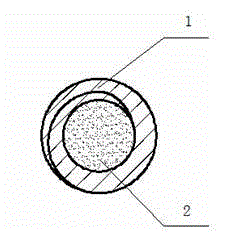

[0035] Such as figure 2 As shown, the diameter of the seam welding wire is 1.6mm, and it is divided into the outer layer homogeneous alloy solder 1 and the inner core solder 2 structurally. The inner core diameter is 0.9mm, and the weight ratio of the outer layer homogeneous alloy solder is 85%. The weight ratio of the inner core flux is 15%. The composition of the outer homogeneous alloy solder is 57% Cu, 39% Zn, 2.0% Sn, 1.2% Mn and 0.8% Ni; the inner core composition is 65% B 2 o 3 , 26% Na 2 O·2B 2 o 3 , 1% CsF and 8% NaF. The butt weld of alloy steel rods (40Cr) with a diameter of 2mm is used for flame brazing, which can be directly brazed into shape, without turbulent flow of brazing filler metal, full brazing seam shape, reliable quality, and the connection tensile strength can reach 320MPa.

Embodiment 3

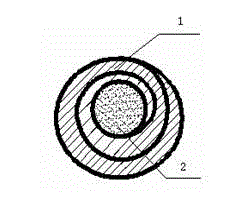

[0037] Such as image 3 As shown, the diameter of the seam welding wire is 1.5mm, which is divided into the outer layer homogeneous alloy solder 1 and the inner core solder 2 structurally, the inner core diameter is 0.9mm, and the weight ratio of the outer layer homogeneous alloy solder is 90%. The weight ratio of the inner core flux is 10%. The composition of the outer homogeneous alloy solder is 61% Cu, 37% Zn, 1.0% Sn, 0.2% Mn, 0.7% Ni and 0.1% Si; the inner core composition is 68% B 2 o 3 , 24% Na 2 O·2B 2 o 3 , 1% CsF and 7% NaF. The butt weld of alloy steel rods (45) with a diameter of 2mm is used for flame brazing, which can be directly brazed to form, without turbulent flow of brazing material, full brazing seam shape, reliable quality, and the connection tensile strength can reach 300MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com