Silver brazing paste and preparation method thereof

A silver brazing and silver welding technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as complex methods, and achieve the effects of simple preparation process, accelerated brazing process, and simple and effective operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

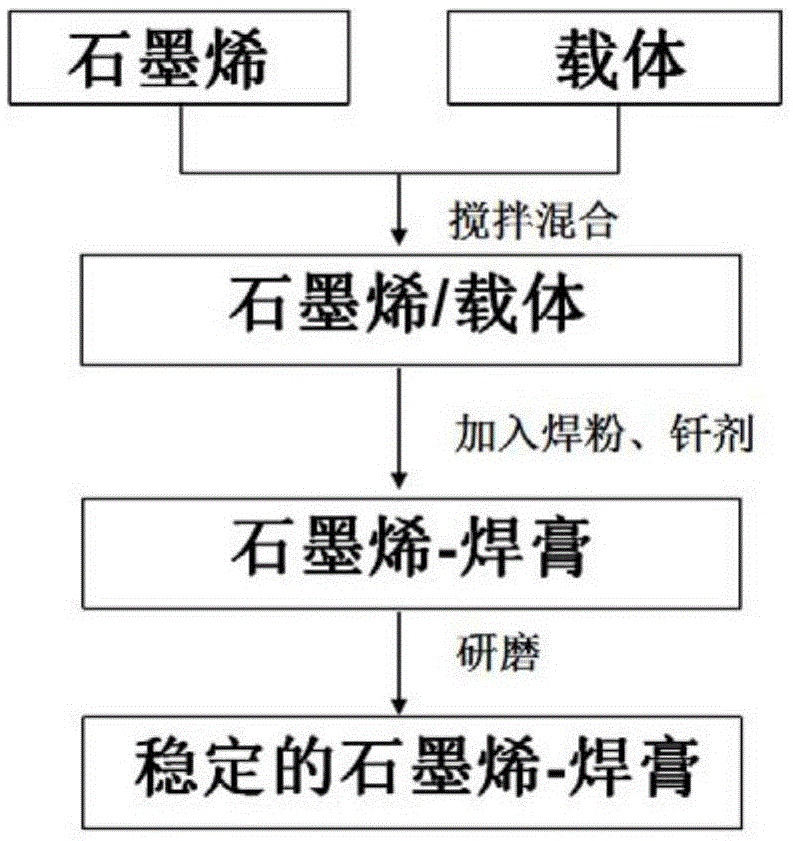

[0033] This embodiment provides a method for preparing a high thermal and conductive silver solder paste, the basic steps are as follows:

[0034] In the first step, weigh 2g of graphite powder and put it into a clean ball mill tank, and weigh stainless steel balls according to the ball-to-material ratio of 10:1 (number ratio of 5mm to 15mm in diameter is 4:1). Then add 100ml of absolute ethanol, cover and seal it, put it into a planetary ball mill for ball milling for 4 hours (rotation 1200rpm, revolution 600rpm), take it out and dry it to obtain dry graphene.

[0035] In the second step, the graphene obtained in the first step is added to the mixed colloid of polyethylene and vaseline (viscosity 5000cp, polyethylene and vaseline mass ratio is 1:1) with an addition of 5wt%, to obtain graphene / carrier decentralized system. Even better, the graphene and the carrier can also be stirred to obtain a graphene / carrier dispersion system.

[0036] In the third step, add silver-coppe...

Embodiment 2

[0040] This embodiment provides a kind of preparation method of high thermal conductivity silver solder paste, and the difference with embodiment 1 is: increase the addition ratio of graphene in the solder paste, increase the number of times of grinding of the three-roll mill, and simultaneously Other related parameters were changed.

[0041] The basic operation steps of the preparation of the present embodiment 2 high thermal conductivity silver solder paste are as follows:

[0042] In the first step, weigh 20g of graphite powder and put it into a clean ball mill jar, and weigh stainless steel balls according to the ball-to-material ratio of 5:1 (number ratio of 5mm to 15mm in diameter is 4:1). Then add 50ml of absolute ethanol, cover and seal it, put it into a planetary ball mill for ball milling for 24h (1200rpm rotation, 600rpm revolution), take it out, dry it and grind it to obtain dry graphene.

[0043] In the second step, the graphene obtained in the first step is added ...

Embodiment 3

[0048] This embodiment provides a kind of preparation method of high thermal conductivity silver solder paste, and the difference with embodiment 1 is: increase the number of times of grinding of the three-roll mill and increase the viscosity of the carrier in the solder paste, and change the Types of solder powder and flux, and related parameters.

[0049] The basic operation steps of the preparation of the present embodiment 3 high thermal conductivity silver solder paste are as follows:

[0050] In the first step, weigh 10g of graphite powder and put it into a clean ball mill jar, and weigh stainless steel balls according to the ball-to-material ratio of 15:1 (number ratio of 5mm to 15mm in diameter is 4:1). Then add 75ml of absolute ethanol, cover and seal, put into a planetary ball mill for ball milling for 15h (1200rpm rotation, 600rpm revolution), take out, dry and grind to obtain dry graphene.

[0051] In the second step, the graphene obtained in the first step is add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com