A frame-type cold plate and its processing method

A frame type, cold plate technology, used in metal processing equipment, manufacturing tools, lighting and heating equipment, etc., can solve the problems affecting the vacuum brazing furnace capacity, material waste, and prolonging the processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

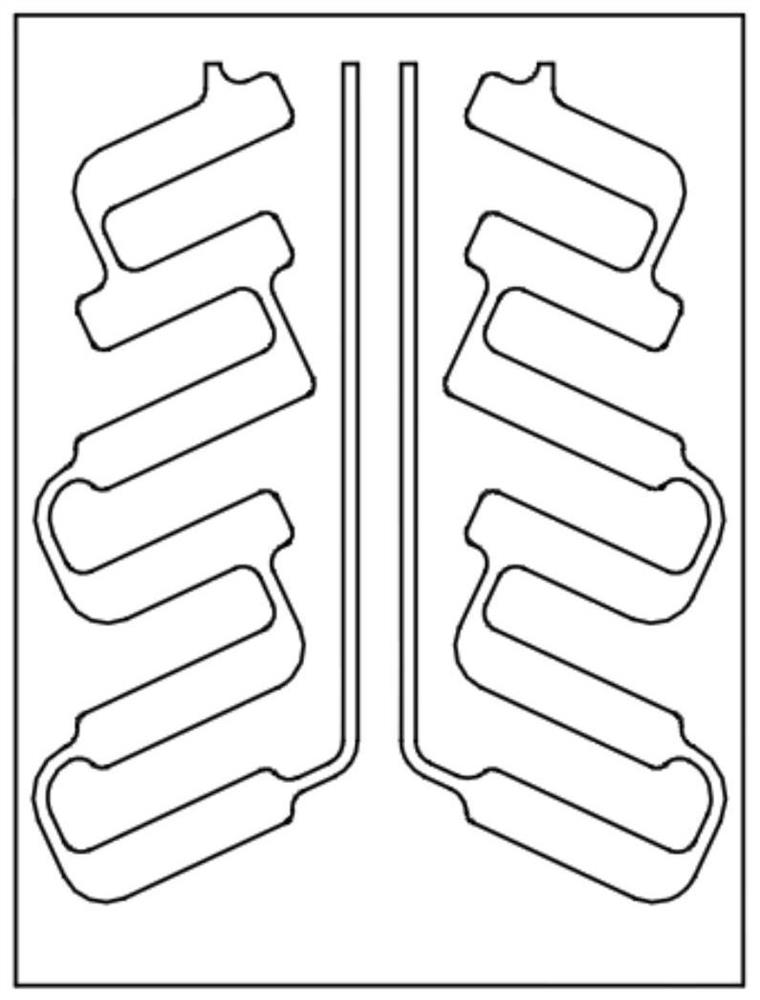

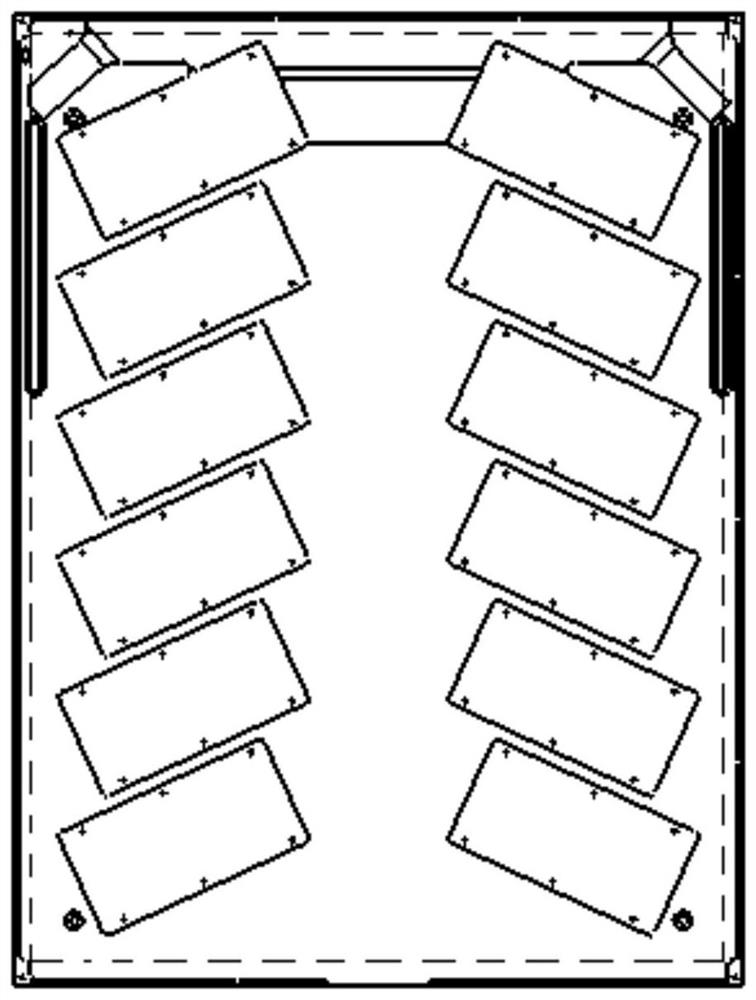

[0030] Such as Figure 4 As shown, the frame-type cold plate includes sequentially connected slot substrates, flat substrates (such as Figure 8 ) and framework 2 (such as Figure 9 and Figure 10 ); the surface of the trough base plate is provided with two mirror-symmetrical water channels that are not closed head to tail, each water channel includes six parallel and equal width vertical water channels of unequal length connected end to end, and the vertical water channels pass through horizontal water channels or arcs The water channels are connected; the flat base plate is a flat piece, parallel to the plane of the tank base plate and brazed to form a cold plate base; the frame 2 is a rectangular frame, and its four edges are connected to the cold plate base through friction stir welding.

[0031] Such as Figure 7 , specifically, each water c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com