Patents

Literature

37results about How to "Consistent pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

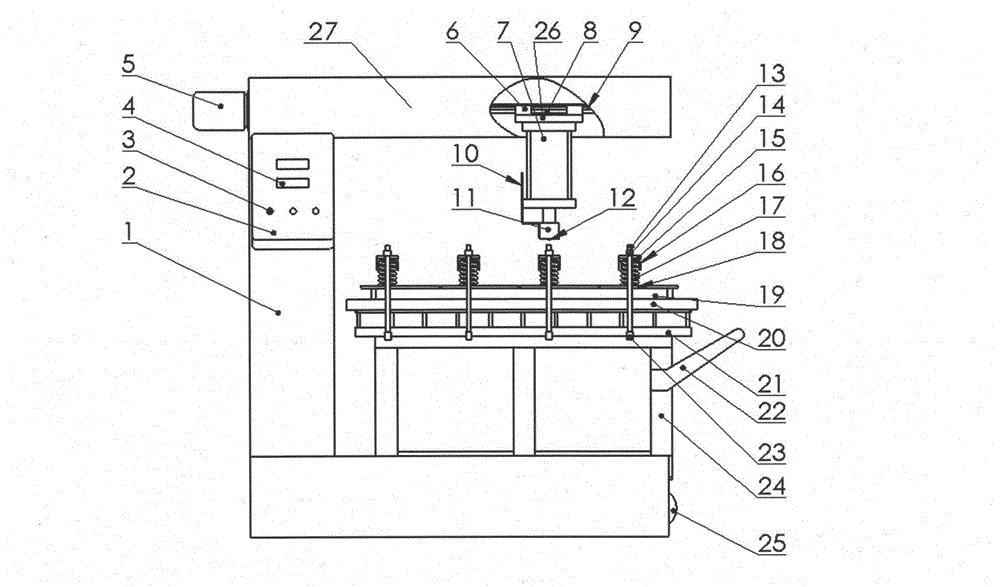

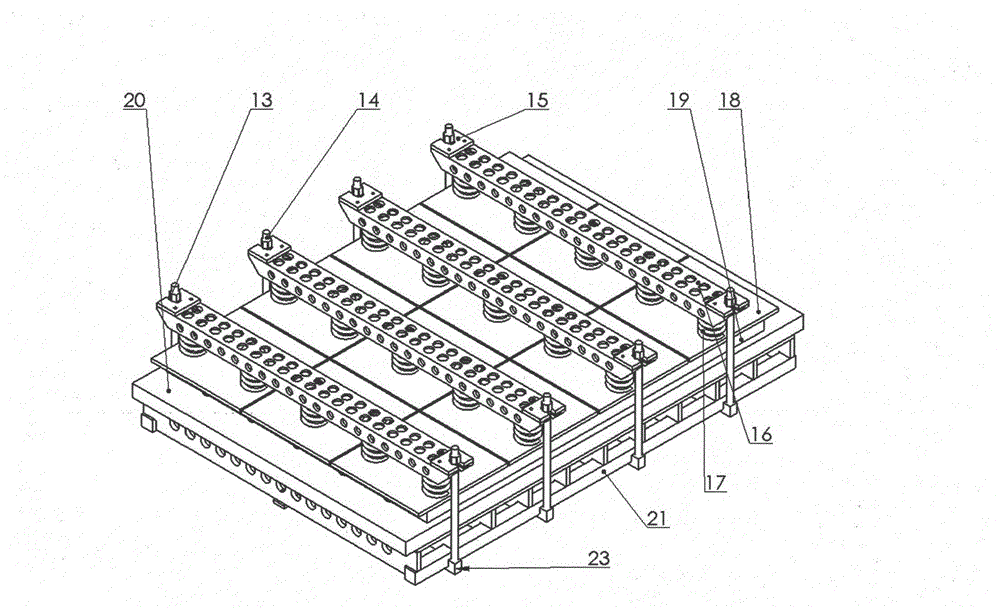

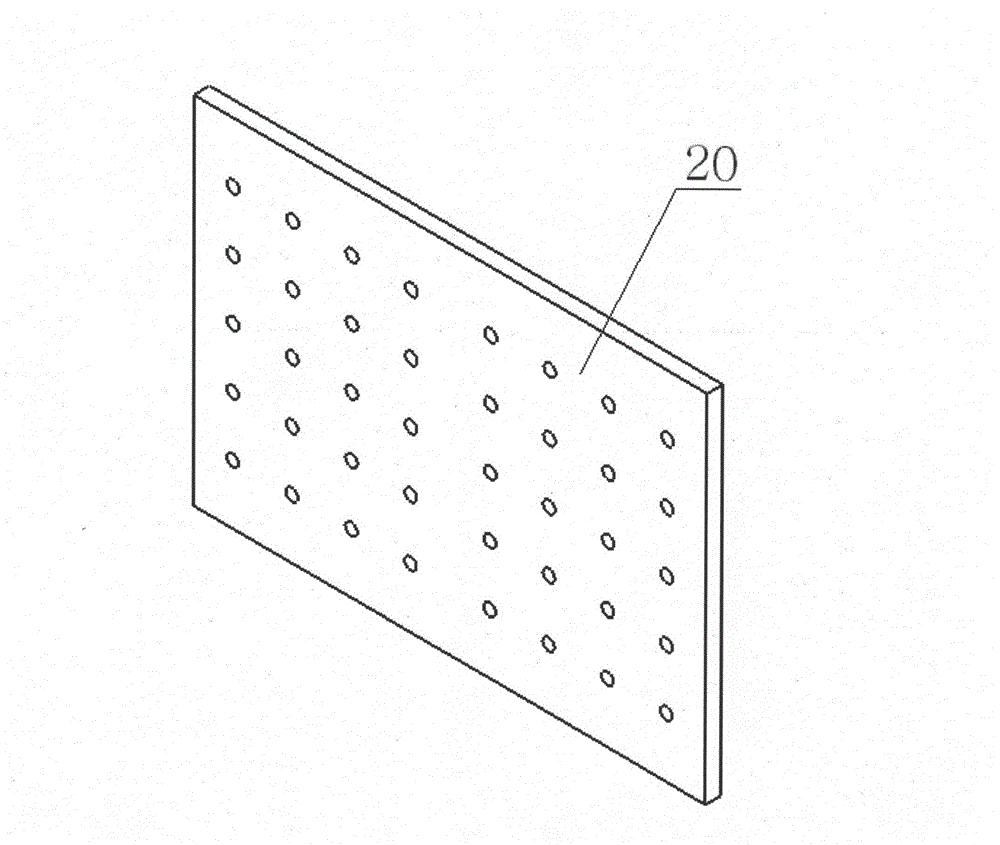

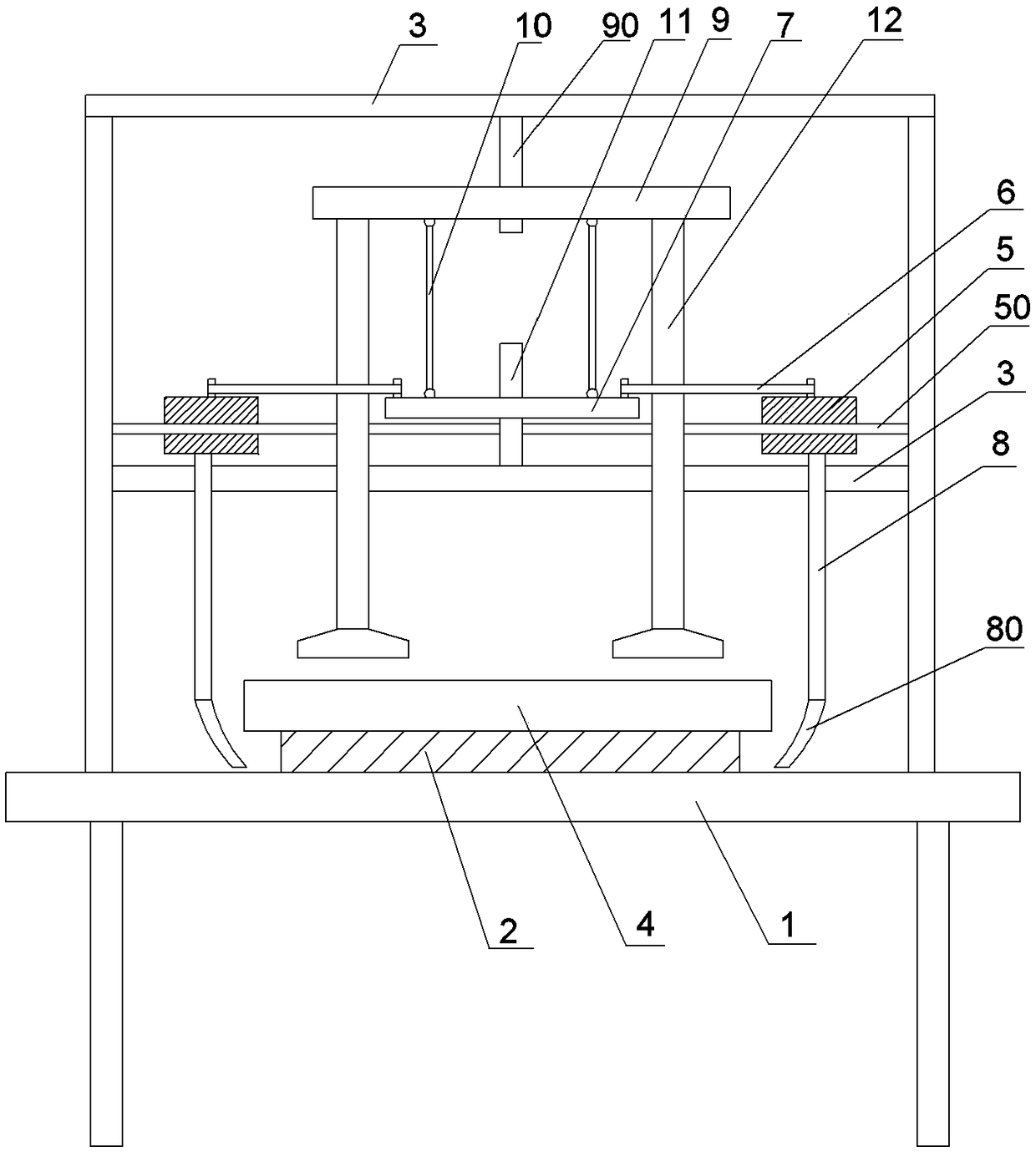

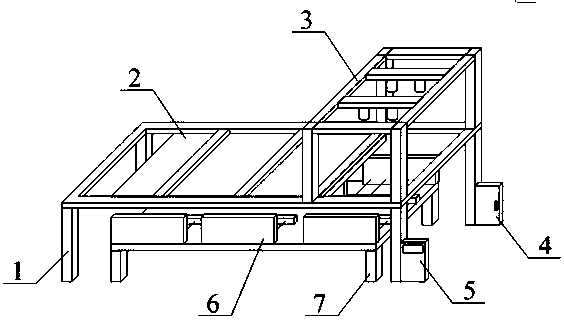

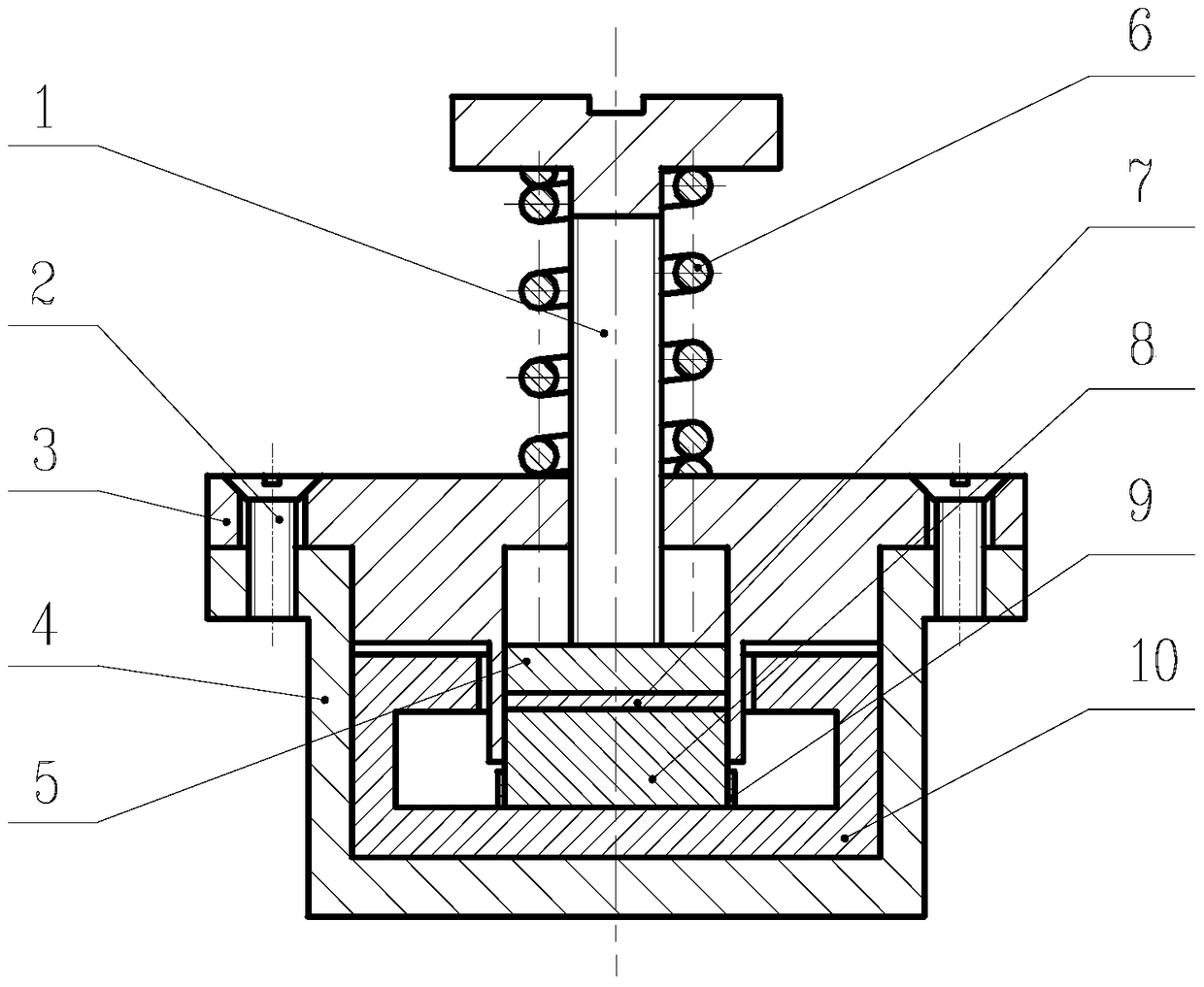

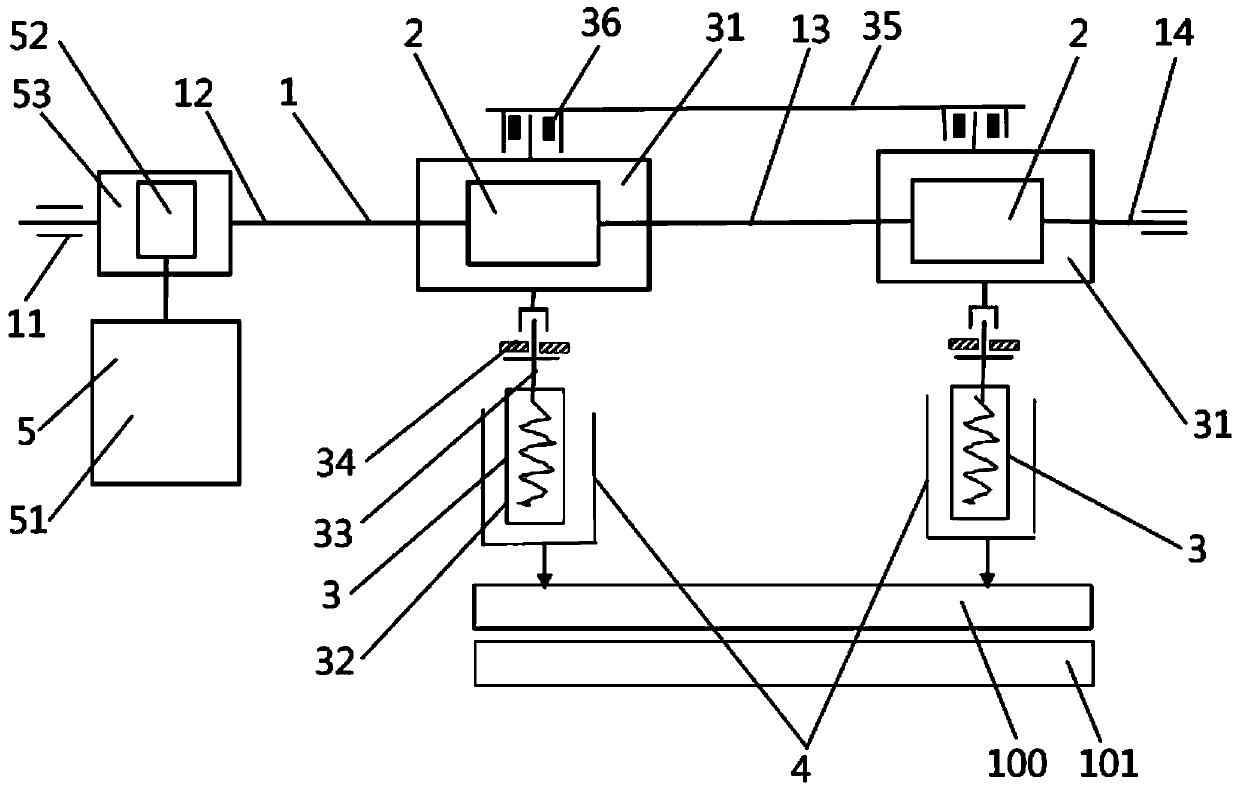

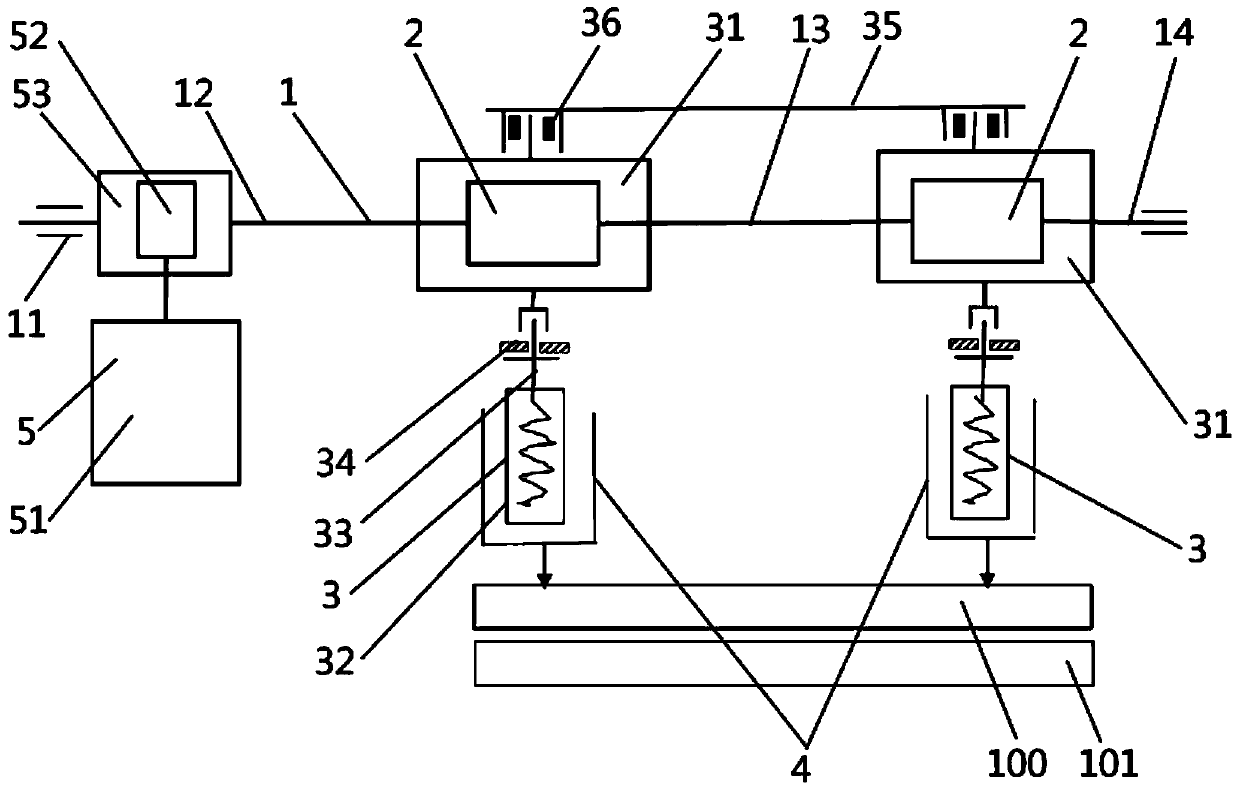

Vacuum brazing tool for water-cooling plate

InactiveCN102873491APrecisely control the total pressing forcePrecisely control the pressing forceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringInternal radiation

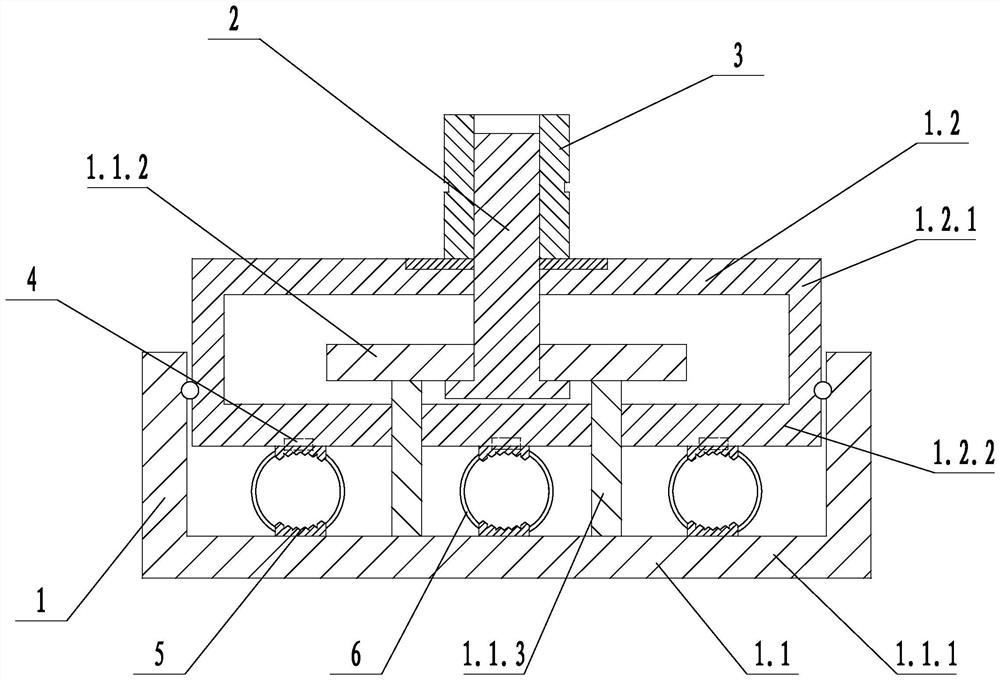

The invention discloses a vacuum brazing tool for a water-cooling plate. The vacuum brazing tool comprises a movable trolley, wherein a clamping device is arranged on the movable trolley and comprises a bottom board, a cover plate and at least one group of clamping device, wherein the bottom board and the cover plate are vertically superposed; and the vacuum brazing tool is characterized by further comprising a C-shaped main frame, wherein a suspension beam is arranged on the upper part of the C-shaped main frame, a vertical moving device which can move along the direction of the suspension beam is arranged on the lower side of the suspension beam, a pressing block is arranged on the bottom end of the vertical moving device, and at least one load sensor is arranged on the bottom of the pressing block. According to the tool, total press fitting force on the water-cooling plate can be accurately controlled, the press fitting force on each part of the water-cooling plate is basically consistent, and thus, the deformation of each clamp is slight and consistent, the service life of each clamp is prolonged, round hole structures of parts such as the bottom board and a pressing board are beneficial to the internal radiation heat adsorption and heat dissipation of a product in a vacuum brazing furnace, so that the brazing efficiency is improved, after the tool is adopted to weld the water-cooling plate, the once finished product rate can reach above 90%, and the tool can be widely applied to the assembling of the water-cooling plate before the vacuum brazing.

Owner:SHANGHAI EAGTOP ELECTRONICS TECH

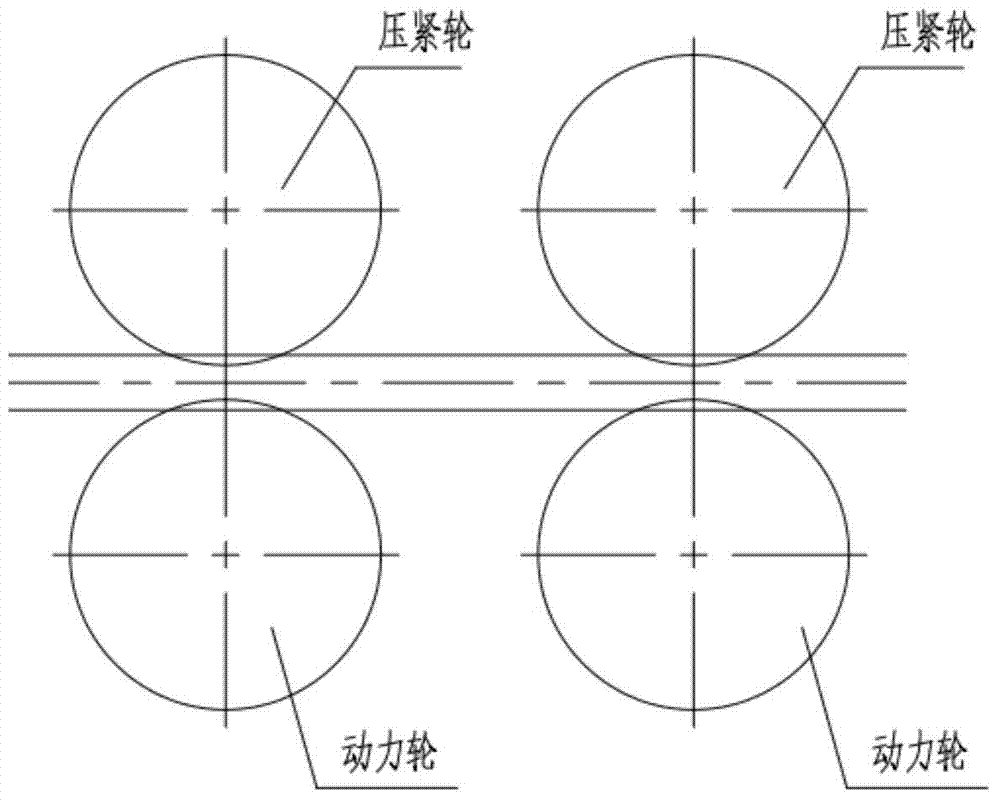

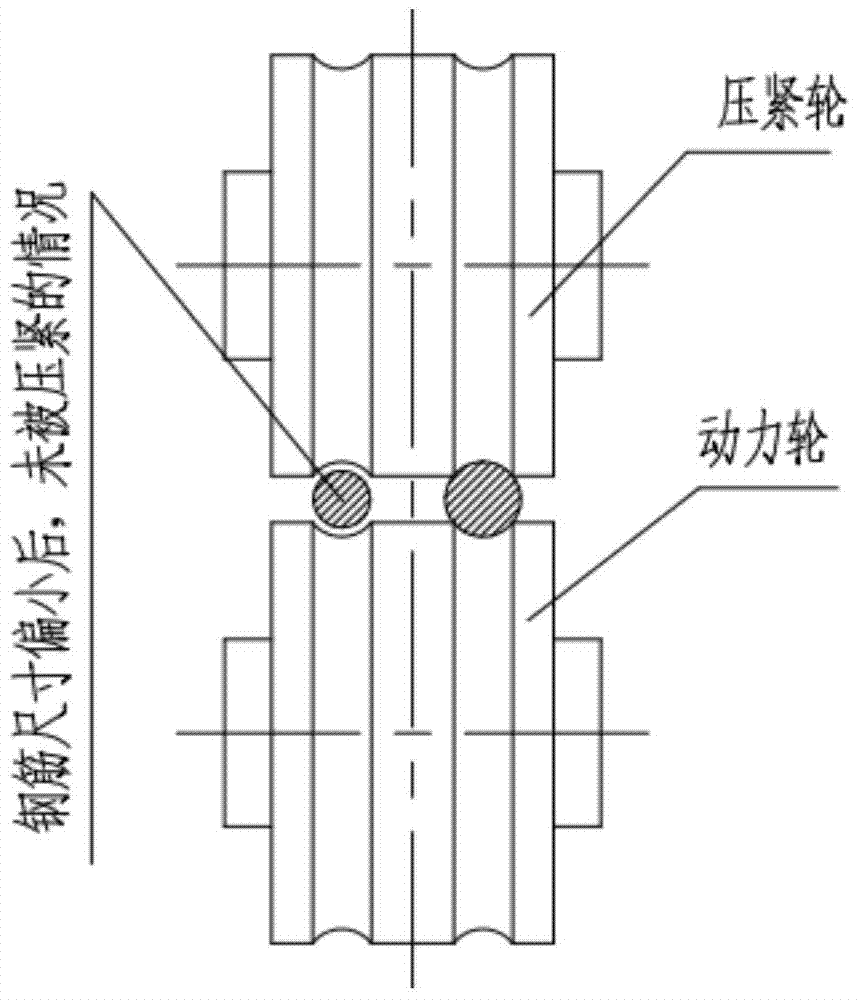

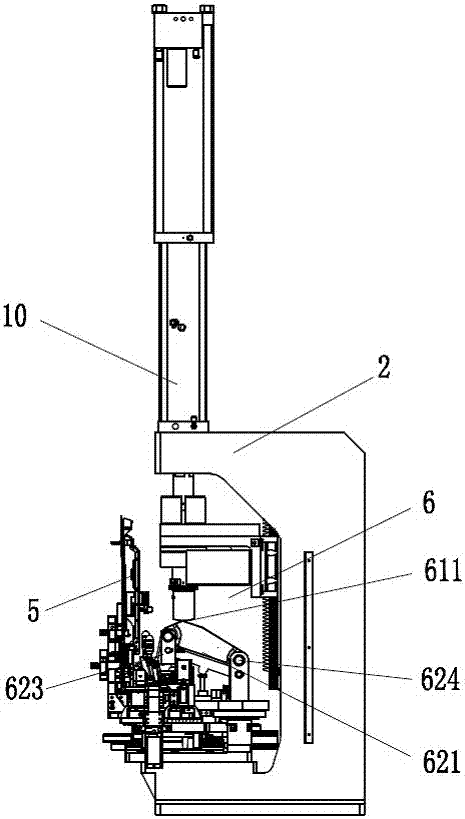

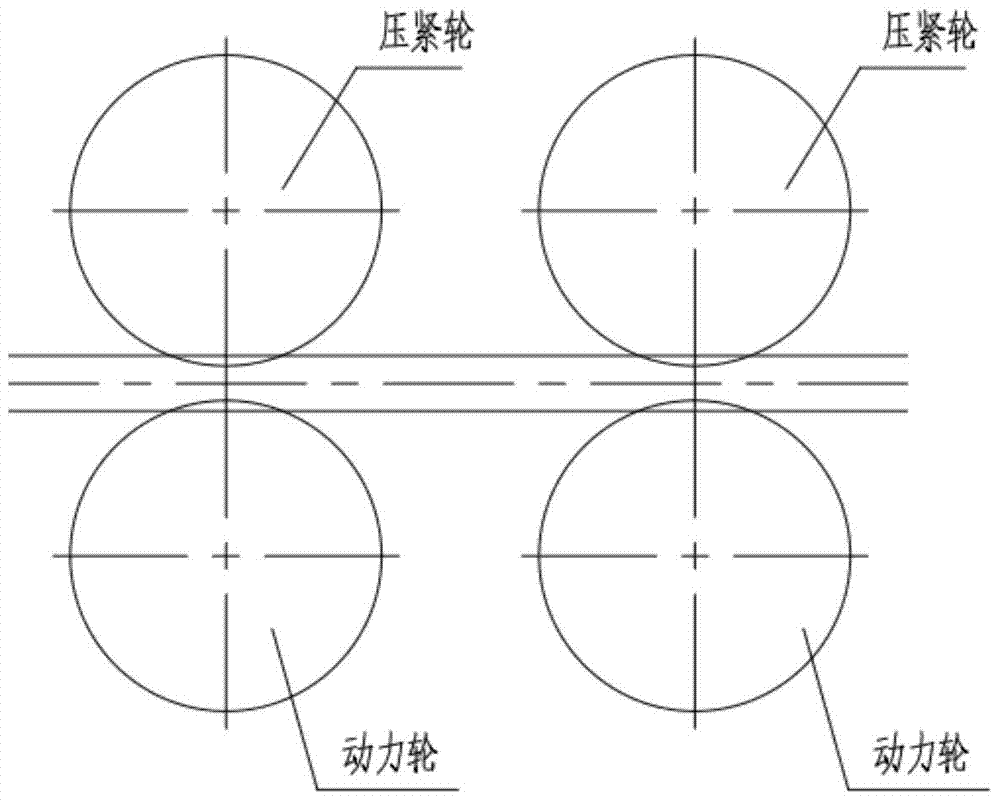

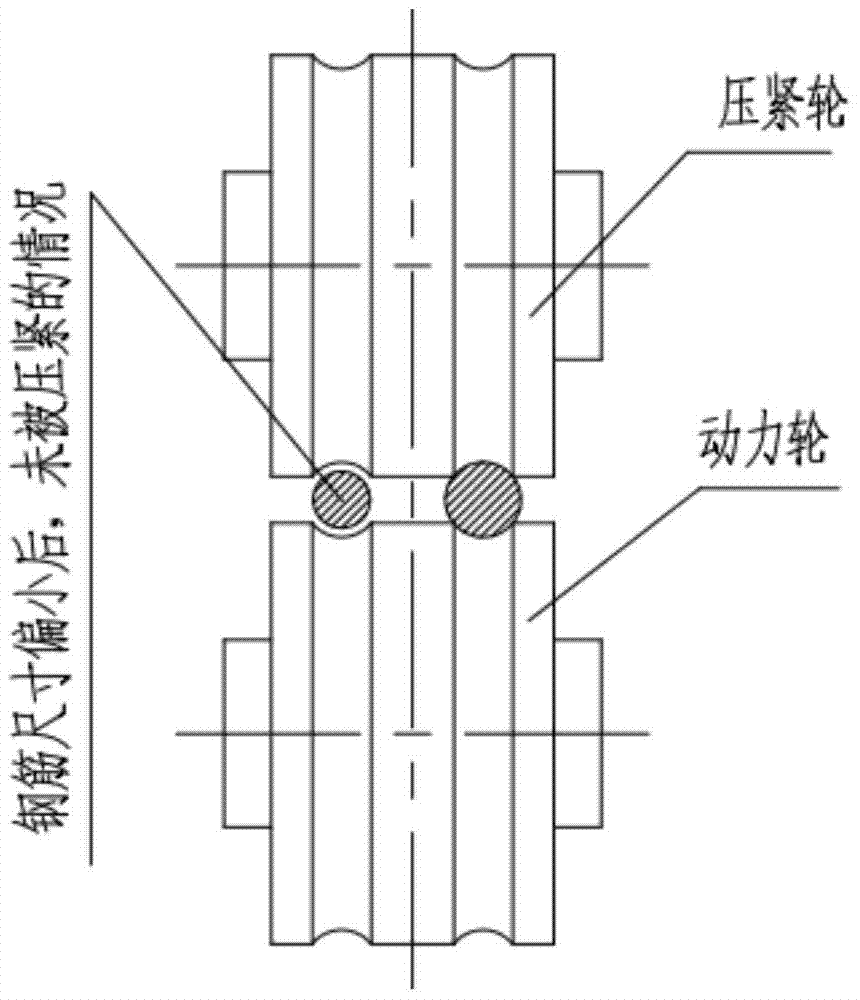

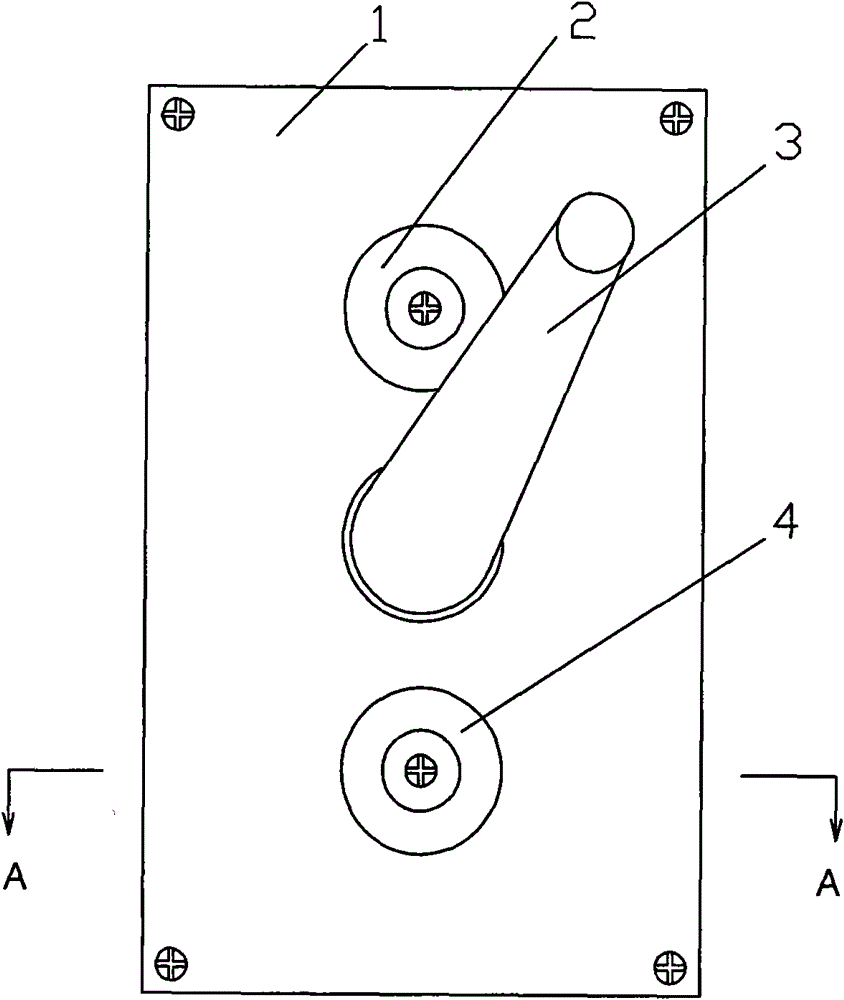

Antiskid device for driving wheel of double-line steel bar hoop bending machine

The invention discloses an antiskid device for a driving wheel of a double-line steel bar hoop bending machine, which comprises a driving wheel driven by a driving main shaft, straightening wheels arranged on two sides of the driving wheel, at least two pressing wheels arranged on two sides of the center line of the driving wheel, and a pressing block connected with the axle centers of the pressing wheels respectively. Furthermore, the antiskid device for the driving wheel of the double-line steel bar hoop bending machine also comprises a down pressing device which is connected with the pressing block. The antiskid device for the driving wheel of the double-line steel bar hoop bending machine has the beneficial effects that: the pressing wheels can be adjusted automatically, so as to ensure that the pressing wheels are pressed on each steel bar all the time and can reliably guarantee that the pressing force trends of two pressing points on each steel bar are consistent, a processed stirrup surface is smooth and has no bruised marks and scratched marks, the phenomenon that the steel bar generates skid in the traction process is solved, and the quality of the steel bar subjected to mechanized processing is improved; the antiskid device for the driving wheel of the double-line steel bar hoop bending machine has the advantages that the structure is simple, the maintenance is convenient, the work is stable, the energy resource is saved, and the processing cost is low.

Owner:韶关市华研机械有限公司

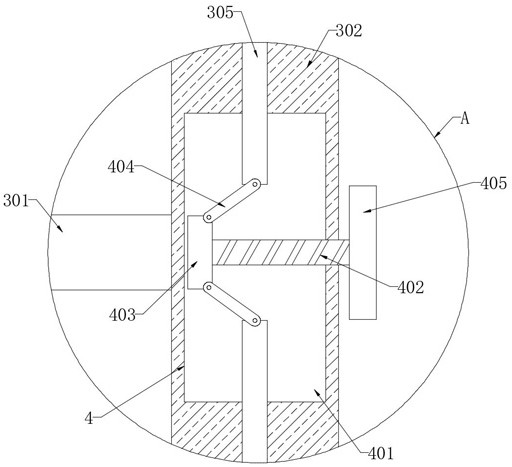

Vehicle-mounted clamping conveying device

The invention belongs to the technical field of vehicle interior production, and particularly discloses a vehicle-mounted clamping conveying device. The vehicle-mounted clamping conveying device comprises a machine frame, the machine frame is detachably connected with a fixing seat, and the fixing seat is slidably connected with two sliding seats. A plurality of clamping jaws are fixedly arrangedat the bottom ends of the sliding seats, and the multiple clamping jaws are distributed in the length direction of the sliding seats. Bending portions are arranged at the bottom ends of the clamping jaws, and the bending portions of every two clamping jaws are oppositely disposed. A conveyor belt is further arranged on the machine frame below the clamping jaws, and a rotating shaft is rotatably connected to the fixing seat between the two sliding seats. A rotating frame is fixedly arranged on the rotating shaft in a sleeving mode, and first connecting rods are separately hinged between the twoends of the rotating frame and the two sliding seats. A sliding frame is slidably connected to the fixing seat above the rotating frame, and the sliding direction of the sliding frame is parallel with the axial direction of the rotating shaft. A plurality of second connecting rods are hinged between the sliding frame and the rotating frame, and a pressing member is fixedly connected to the bottomof the sliding frame. The operation of the assembly and disassembly process of workpieces of the vehicle-mounted clamping conveying device is simple.

Owner:SHANDONG STREET MOBILE SHOP NEW ENERGY TECH CO LTD

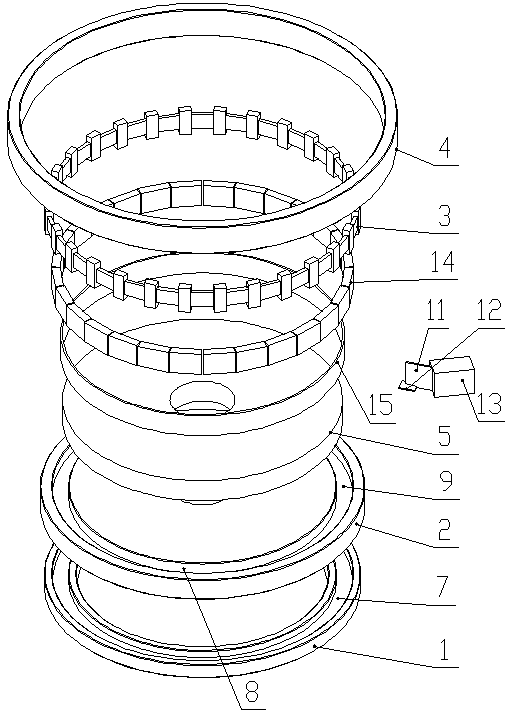

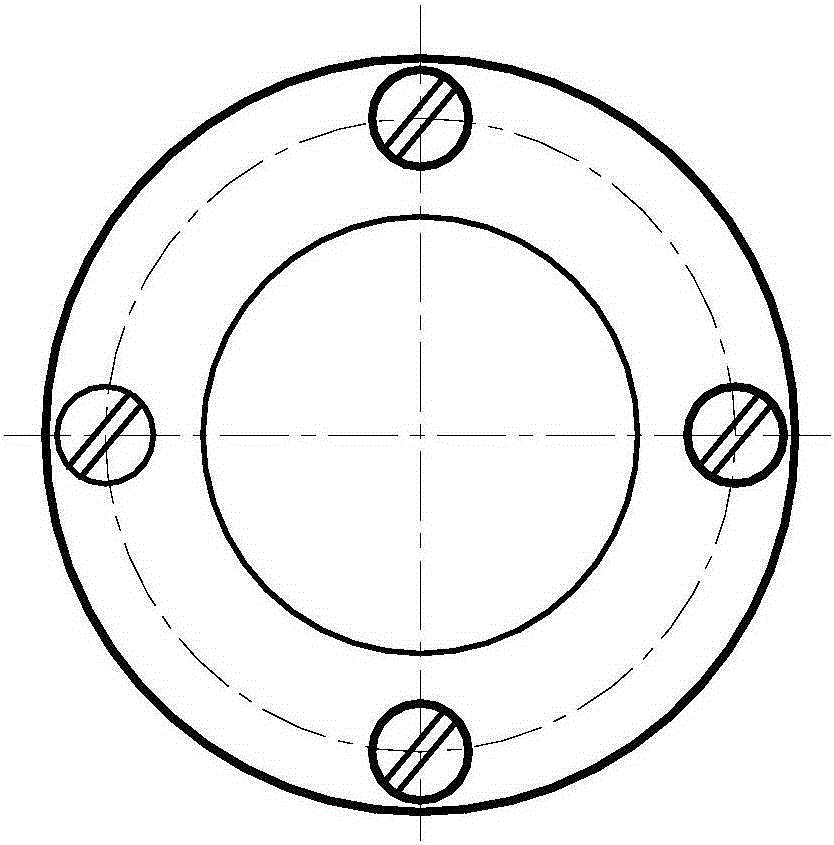

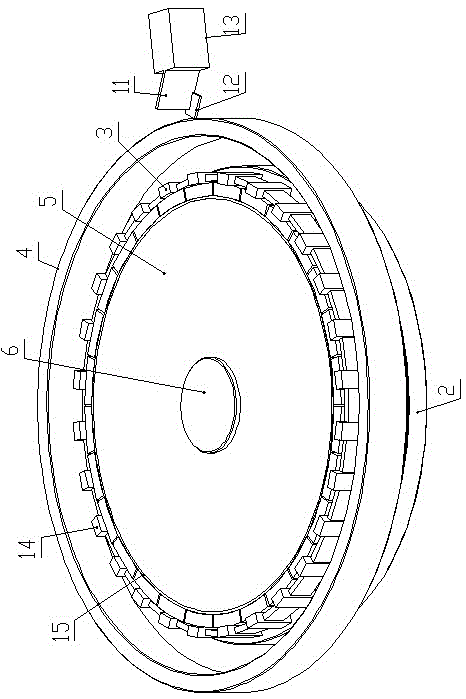

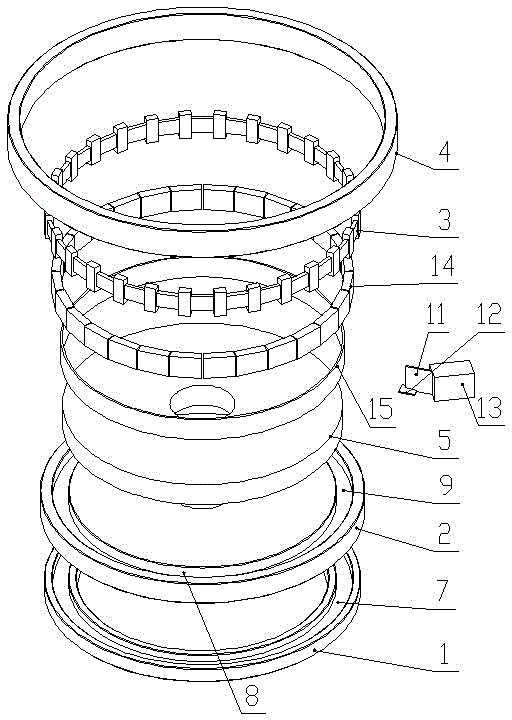

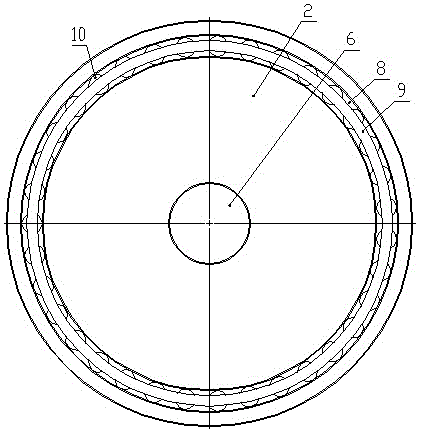

Device and method for solidifying superhard-material grinding wheel abrasive block with substrate

ActiveCN103949989AImprove bonding efficiencyCured Strength Consistency GuaranteeGrinding devicesAdhesiveAbrasive

The invention discloses a device for solidifying a superhard-material grinding wheel abrasive block with a substrate. The device comprises a bottom ring, a rotary disc, an adhesive coating mechanism, an elastic magnetic compression ring and an electromagnetic ring. A method for solidifying the superhard-material grinding wheel abrasive block with the substrate comprises the following specific steps: (1) mounting the grinding wheel substrate on the rotary disc, and coating an adhesive; (2) locating the abrasive block and adhering the abrasive block to the grinding wheel substrate; (3) solidifying a bonding layer between the abrasive block and the grinding wheel substrate. According to the invention, the bonding layer is controllable in thickness; the thickness of the adhesive on the grinding wheel substrate and the grinding wheel abrasive block is uniform; the bonding pressing force of the grinding wheel abrasive block is controllable, so that the bonding efficiency of the abrasive block is improved; the uniformity of the solidifying strength between the abrasive block and the grinding wheel substrate is ensured, the energy can be saved, and the production efficiency is high.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

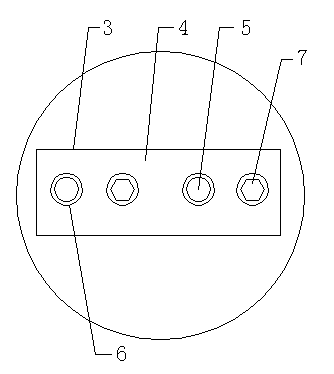

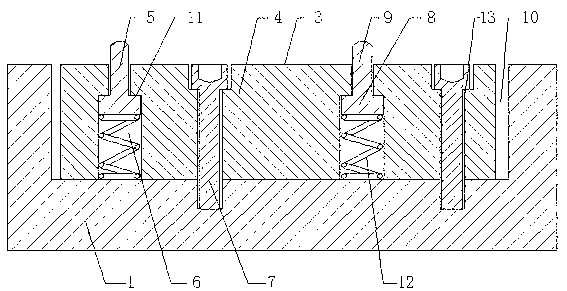

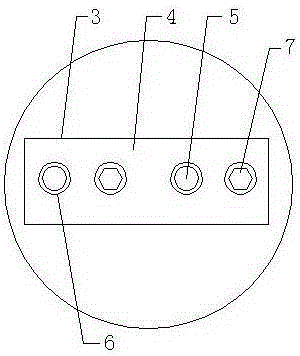

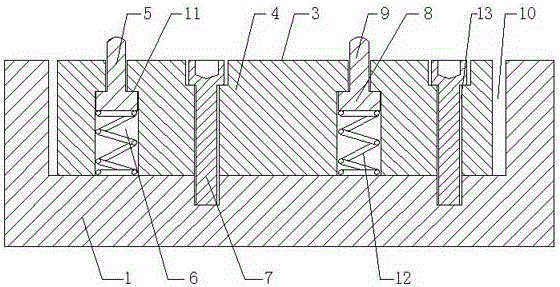

Low-pressure injection molding mold

ActiveCN102975335AReduce manufacturing costSimple structureCoatingsEngineeringElectrical and Electronics engineering

The invention discloses a low-pressure injection molding mold comprising a fixed mold, a mold core, and a surface material pressing mechanism. The mold core is arranged on the fixed mold. The surface pressing mechanism is composed of a plurality of pressing devices. A plurality of recesses are provided around the mold core. The pressing devices are fixedly arranged in the recesses. The pressing devices are composed of limiting blocks, pins, and elastic elements. The limiting blocks are fixedly arranged on the fixed mold. At least one limiting hole is arranged on each limiting block. The pins and the elastic elements are arranged in the limiting holes. One part of the pin extends out of the limiting hole. The elastic elements are arranged below the pins. The other ends of the elastic elements bear against the fixed mold. The mold has the advantages of simple structure, low cost, high product molding qualification rate, and stable and reliable application.

Owner:CHENGDU AEROSPACE MOLD & PLASTIC CO LTD

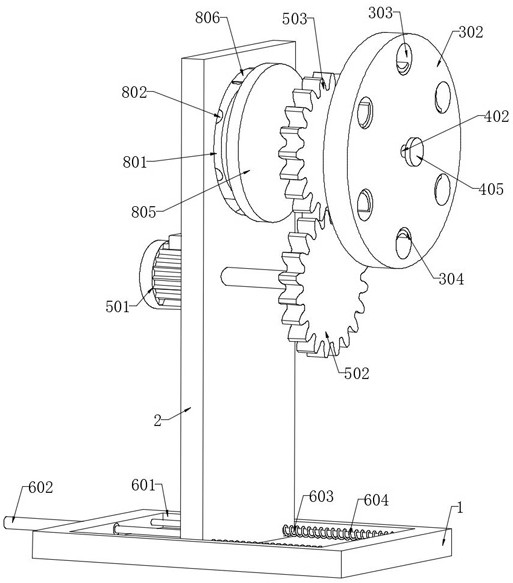

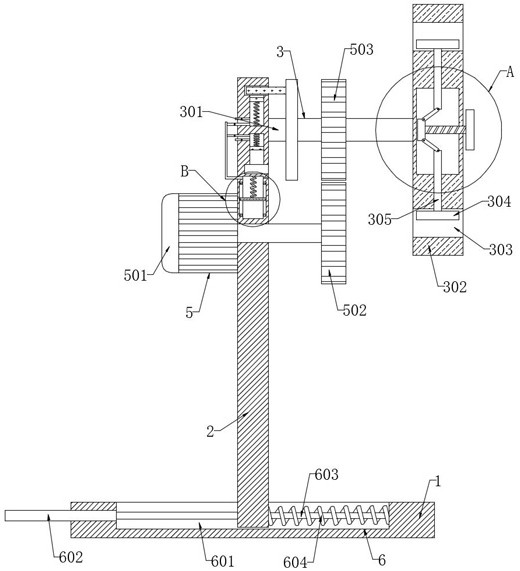

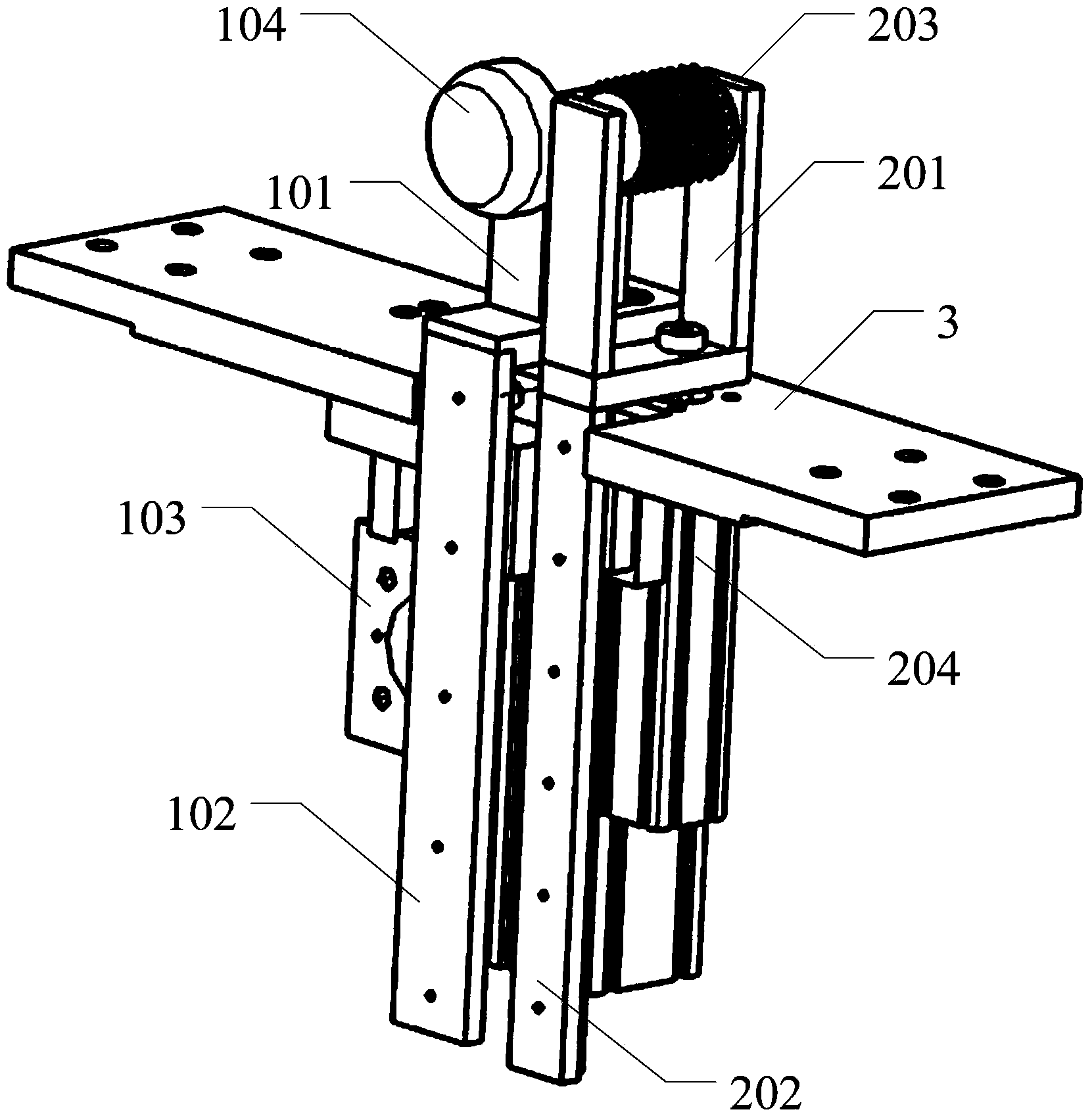

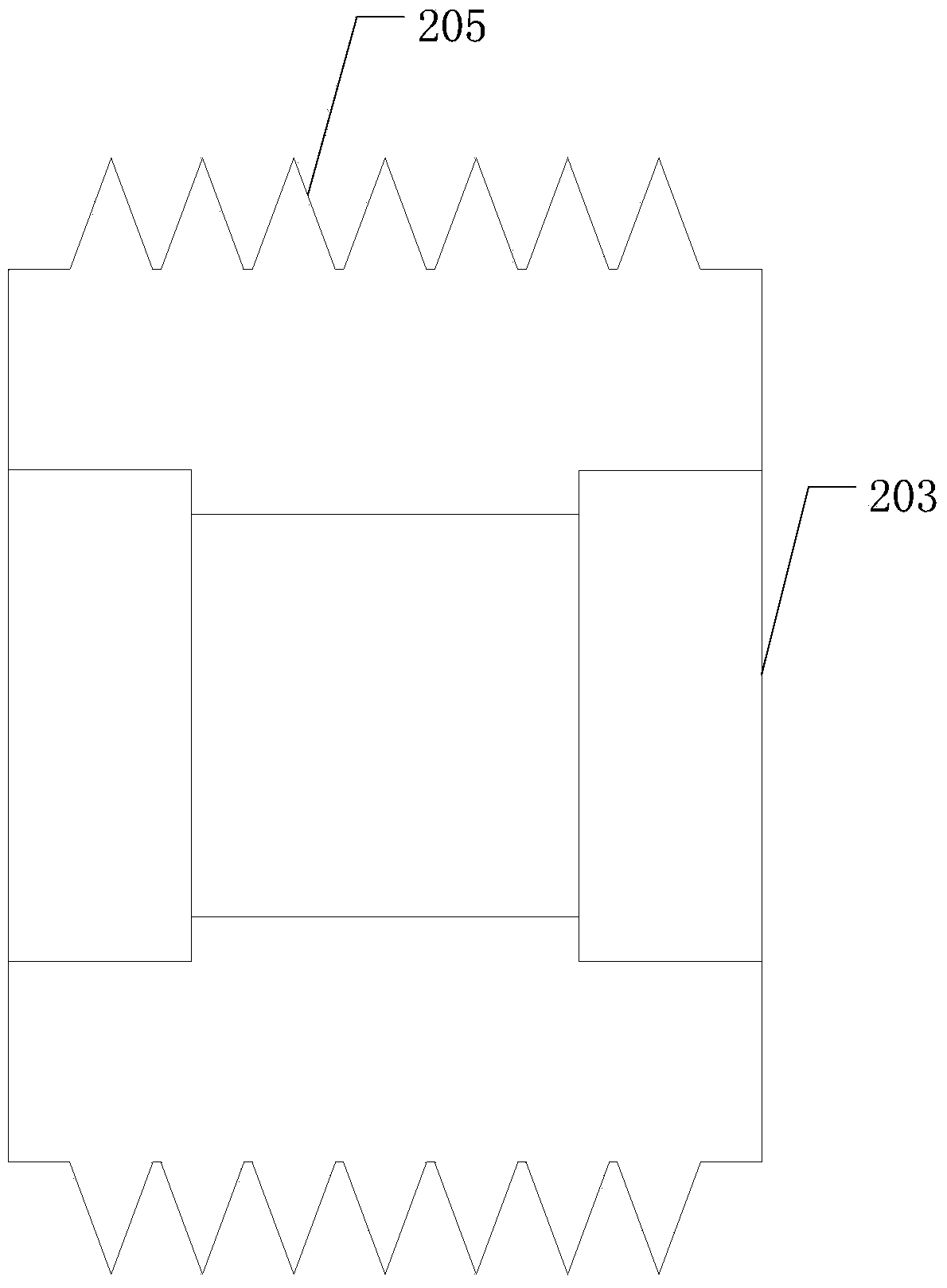

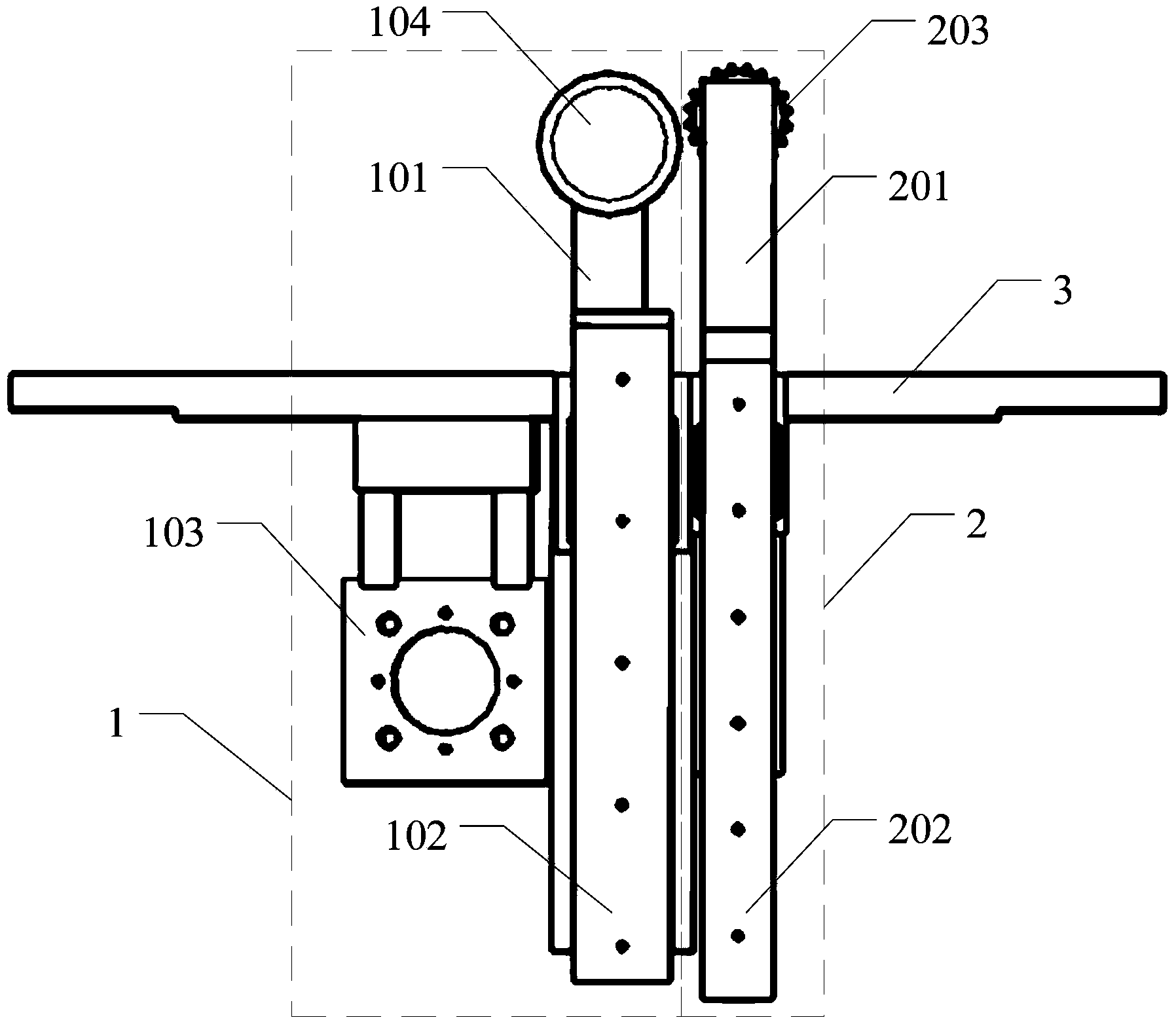

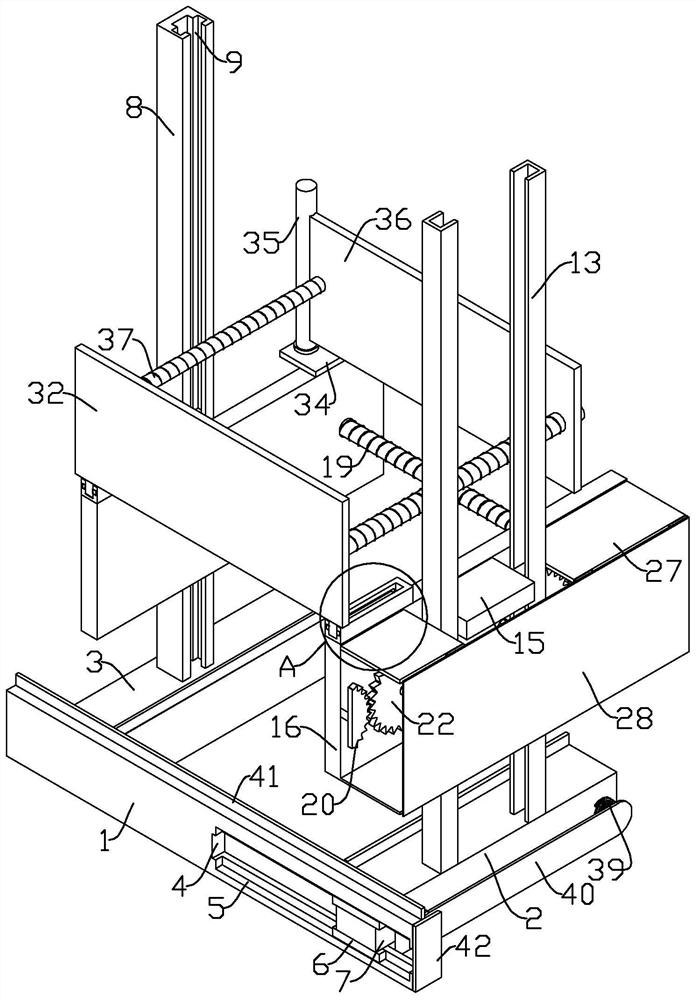

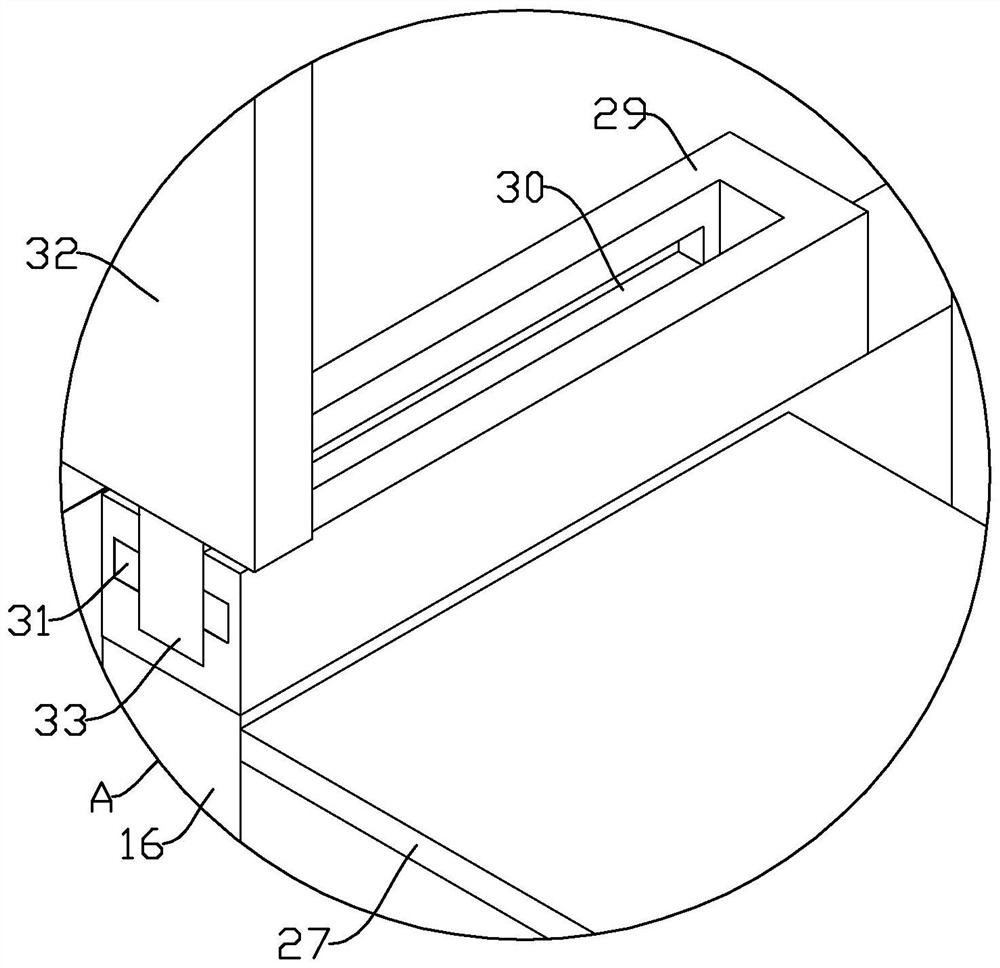

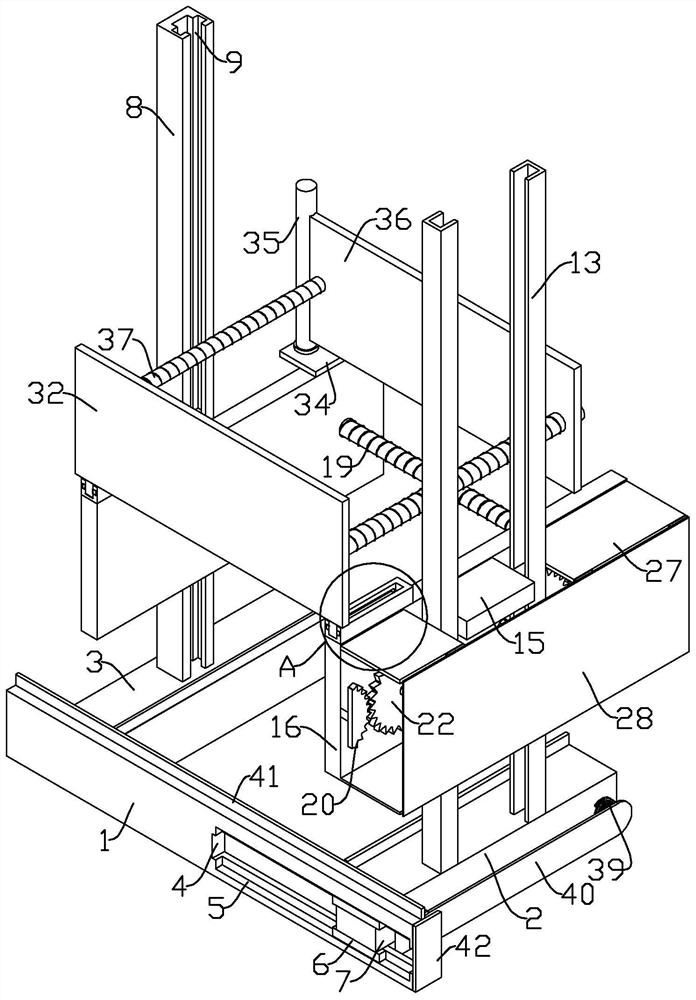

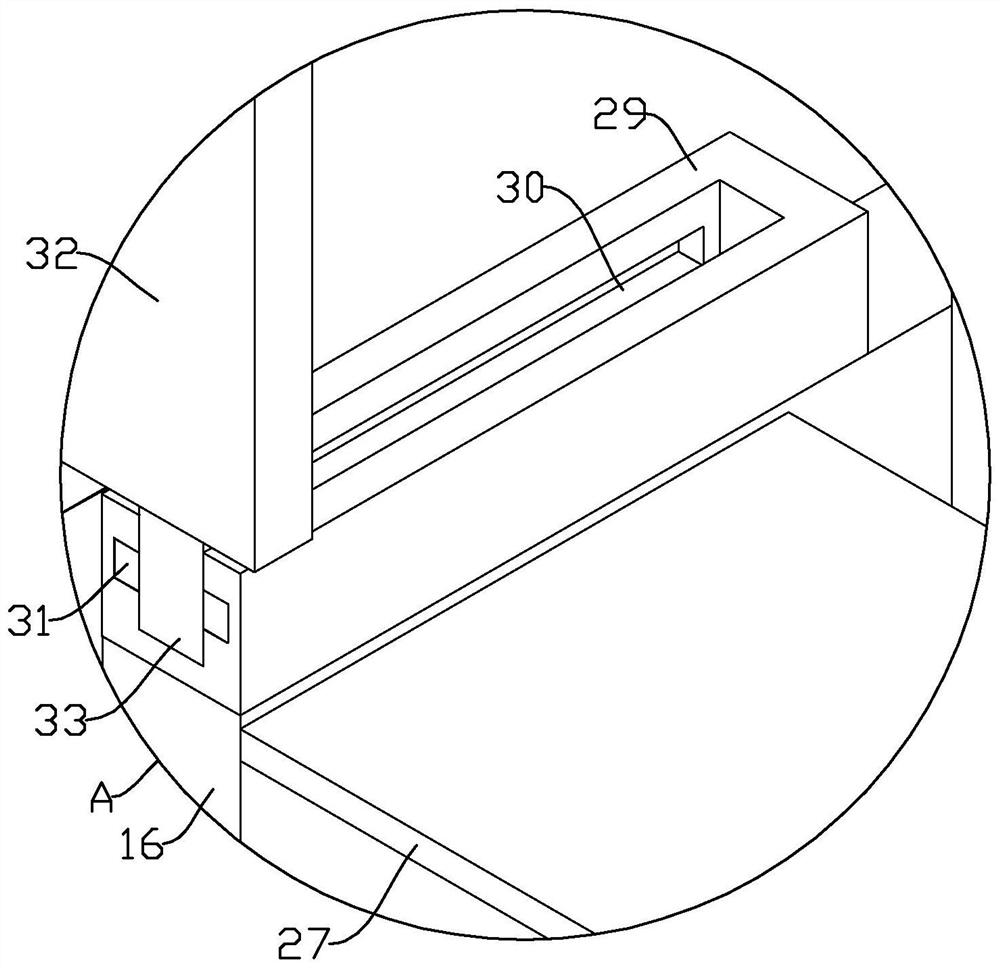

Forming equipment for hemp rope production

InactiveCN112941942AConsistent pressing forceQuality assuranceRope making machinesControl theoryScrew thread

The invention discloses forming equipment for hemp rope production. The equipment comprises a fixed seat, a vertical plate, a winding mechanism, a moving mechanism, a driving mechanism, an adjusting mechanism, a power supply mechanism, a control mechanism and a pumping mechanism, wherein the winding mechanism for winding hemp ropes is rotationally connected to the vertical plate; the moving mechanism for moving and clamping the hemp ropes is fixedly connected to the winding mechanism; the driving mechanism for driving the winding mechanism to rotate is fixedly connected to the vertical plate; and the adjusting mechanism for adjusting the position of the vertical plate is arranged at the upper end of the fixed seat. According to the invention, a rotating disc is rotated to drive a threaded rod to rotate, then a sliding block is driven to slide on the inner wall of a containing groove, then the sliding block drives multiple arc-shaped plates to move in the direction away from one another through multiple rotating rods, and then the multiple arc-shaped plates can press and fix the hemp ropes located in multiple round holes at the same time, so that the hemp ropes do not need to be adjusted one by one, the fixing efficiency is improved, the pressing force for the multiple hemp ropes is consistent, and the quality of the formed hemp ropes is ensured.

Owner:南通高隆纺织科技有限公司

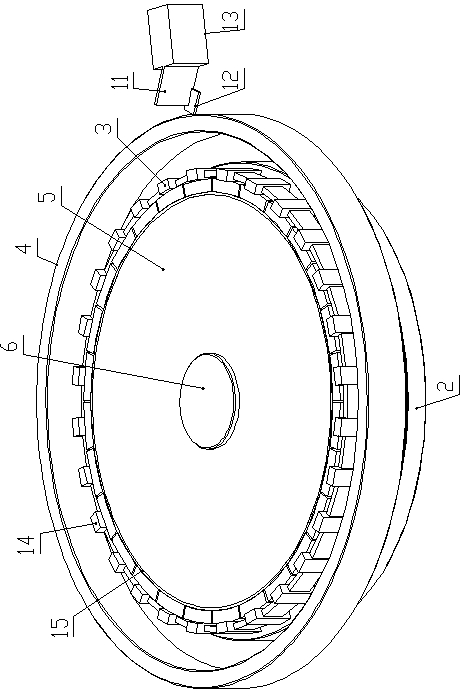

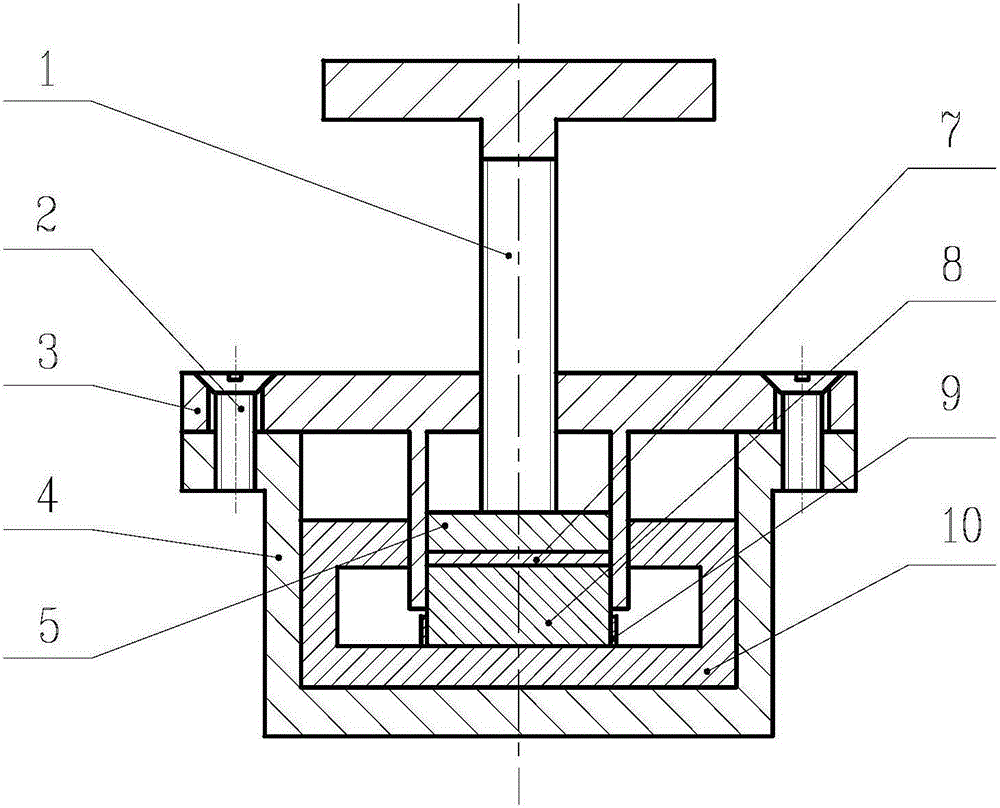

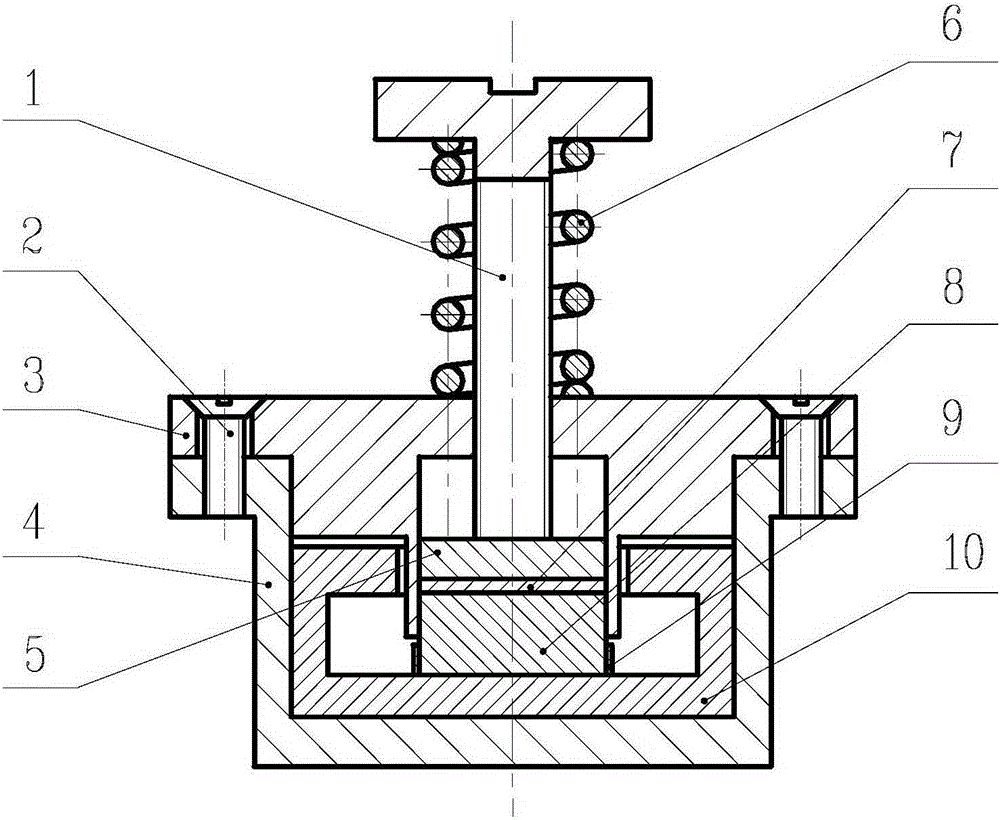

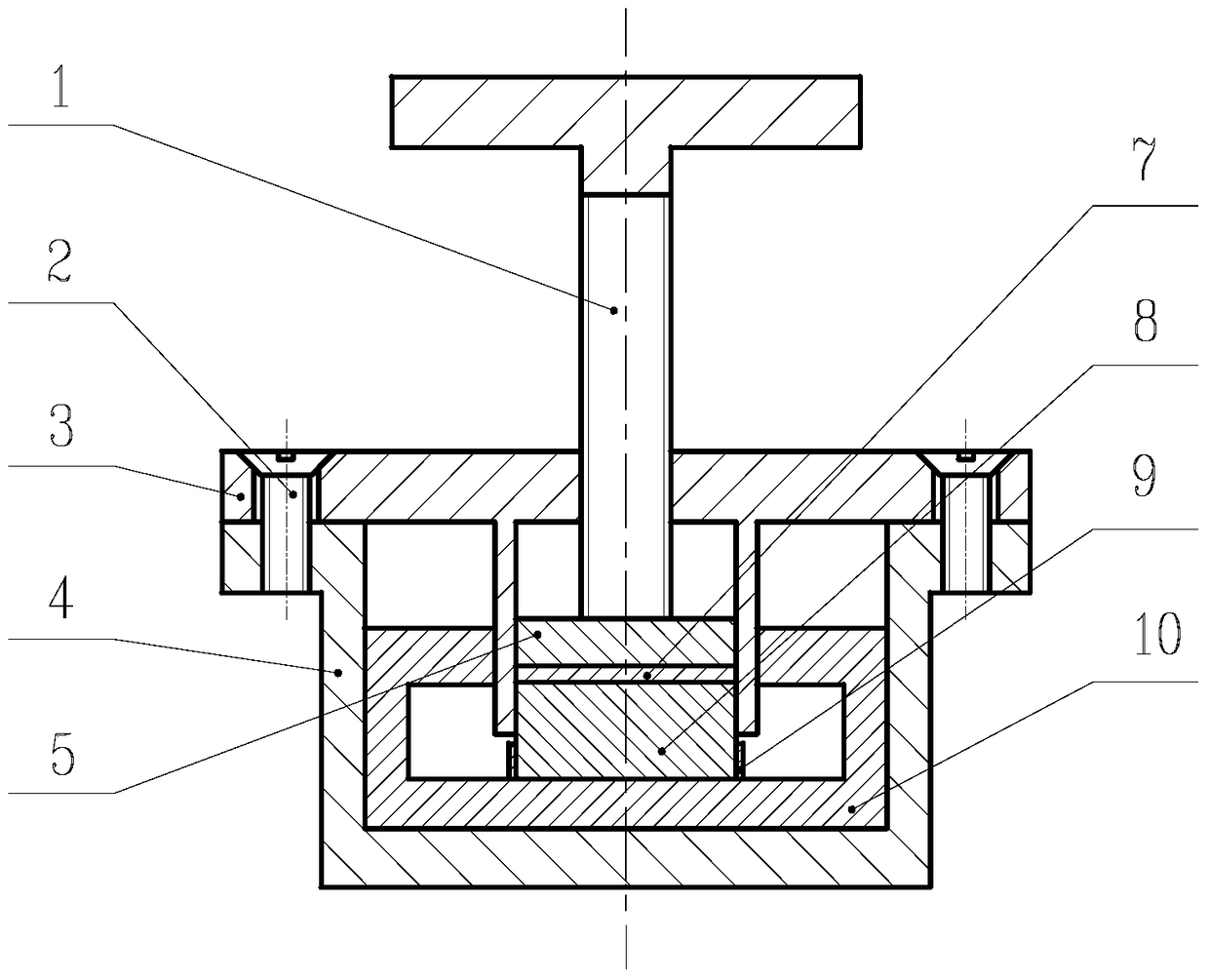

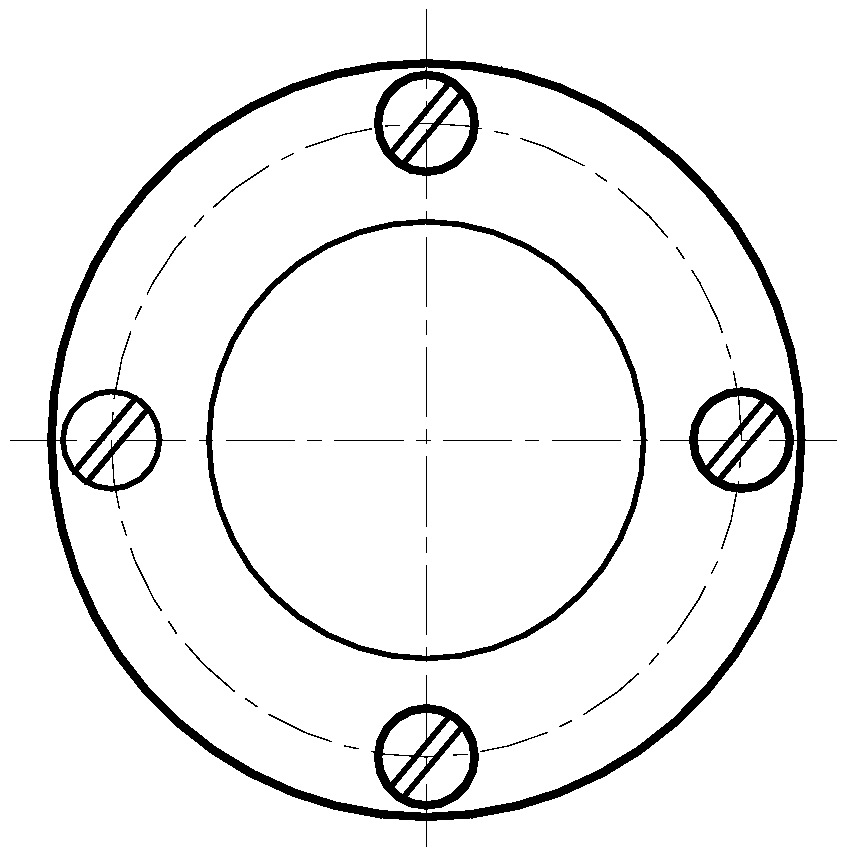

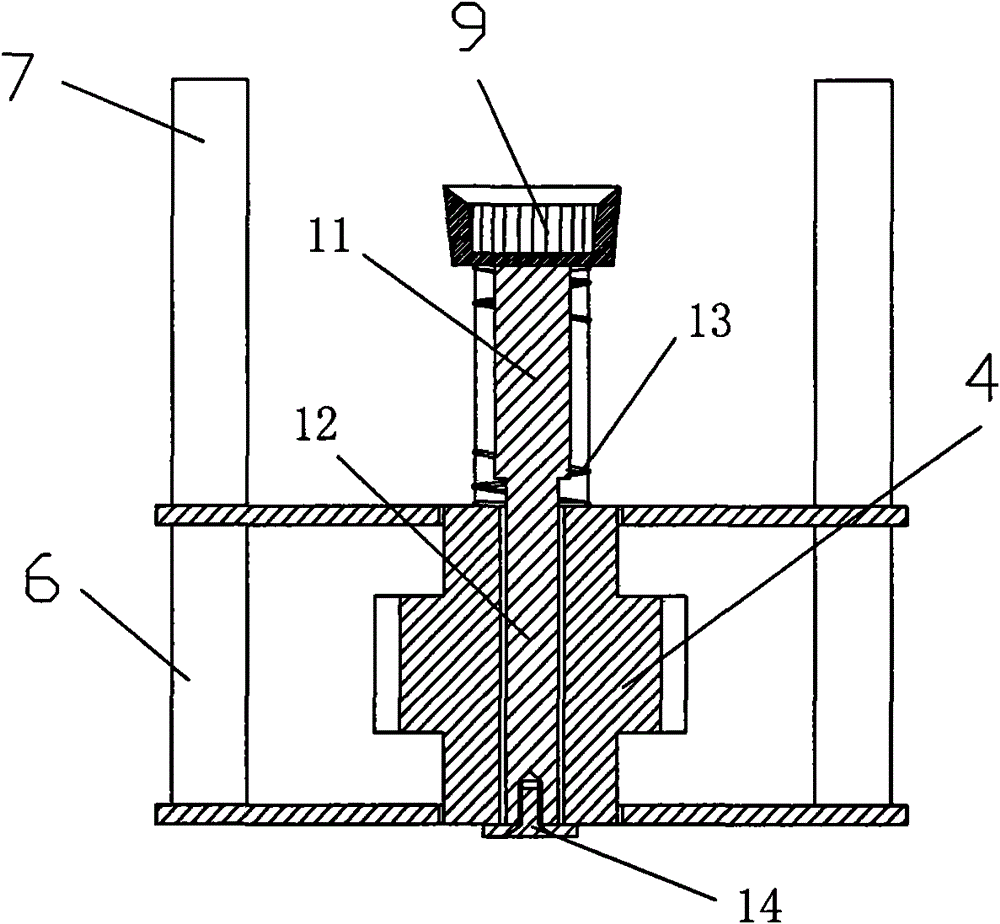

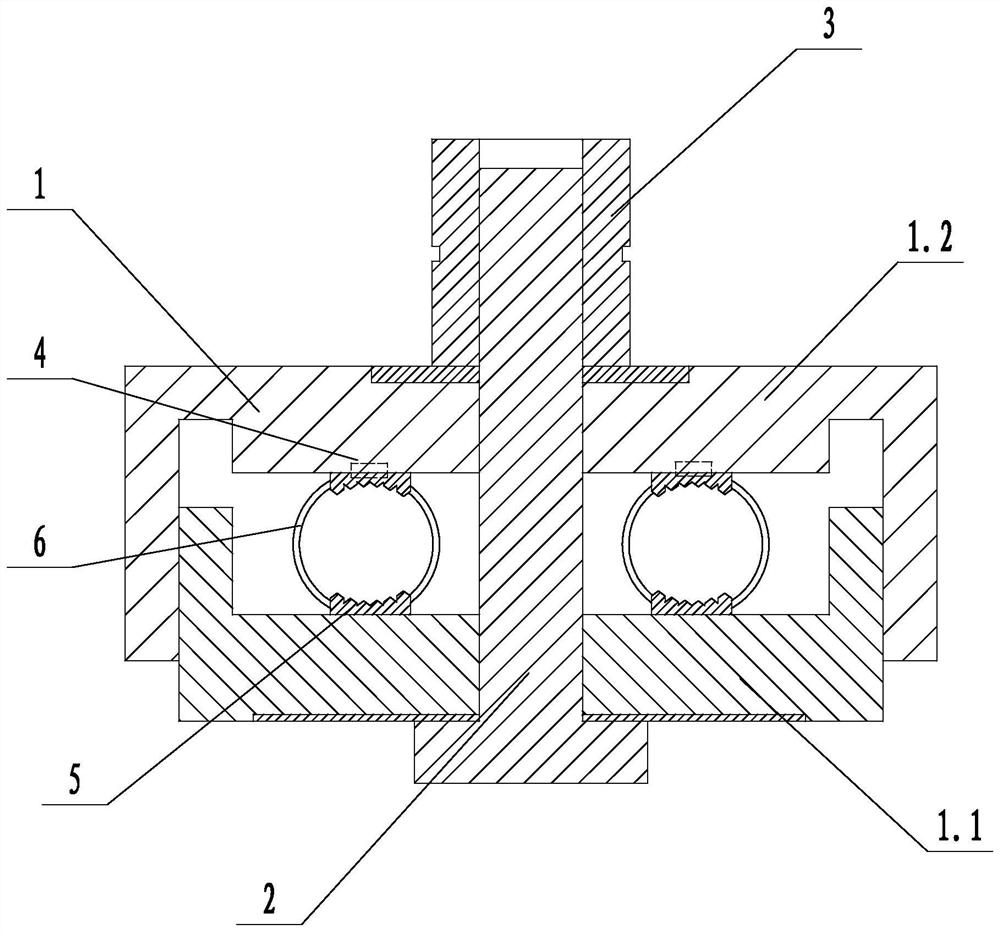

Torquer magnetic steel assembly device and method

ActiveCN106555796AThe pressing force remains the sameConsistent pressing forceFastening meansArchitectural engineeringEngineering

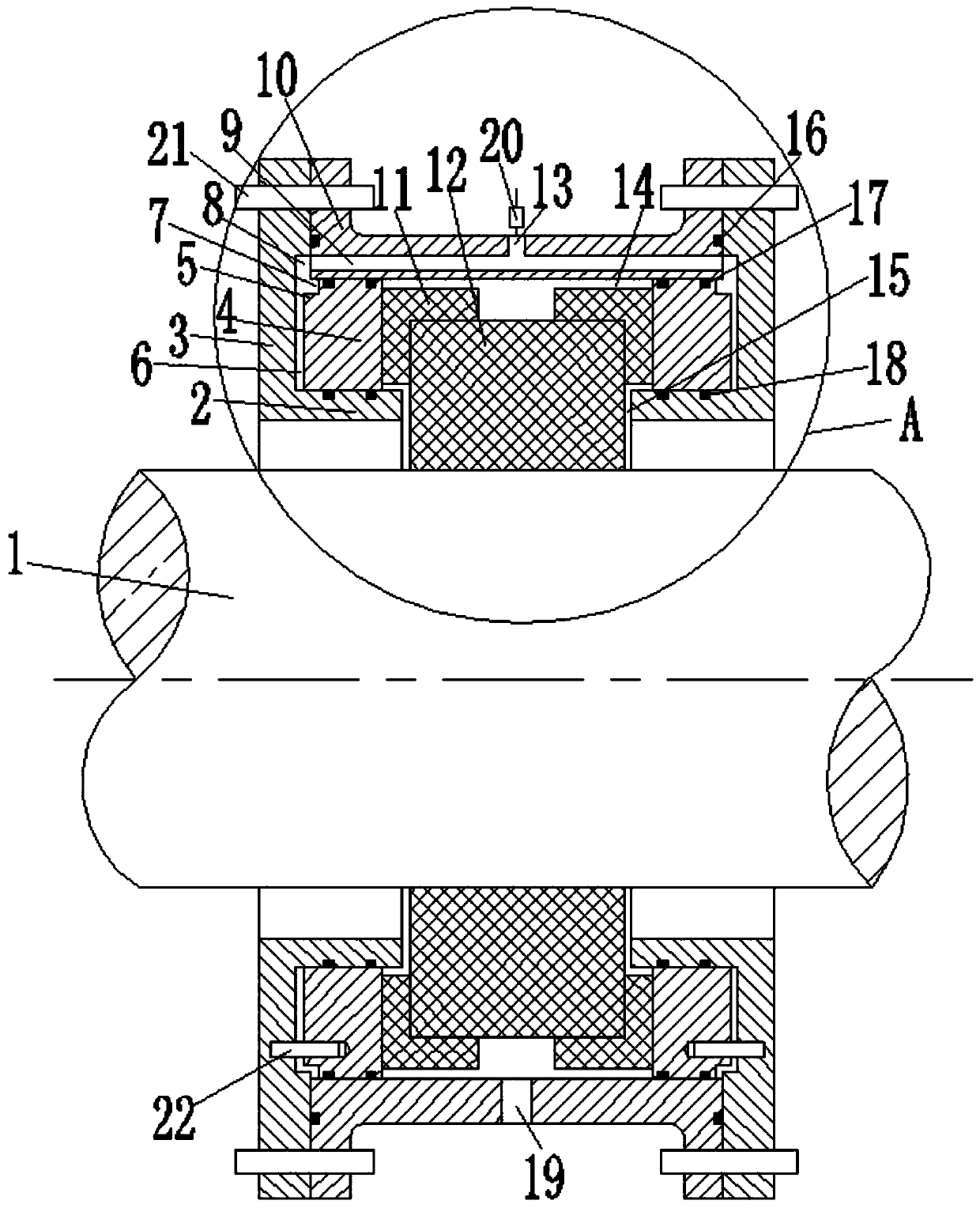

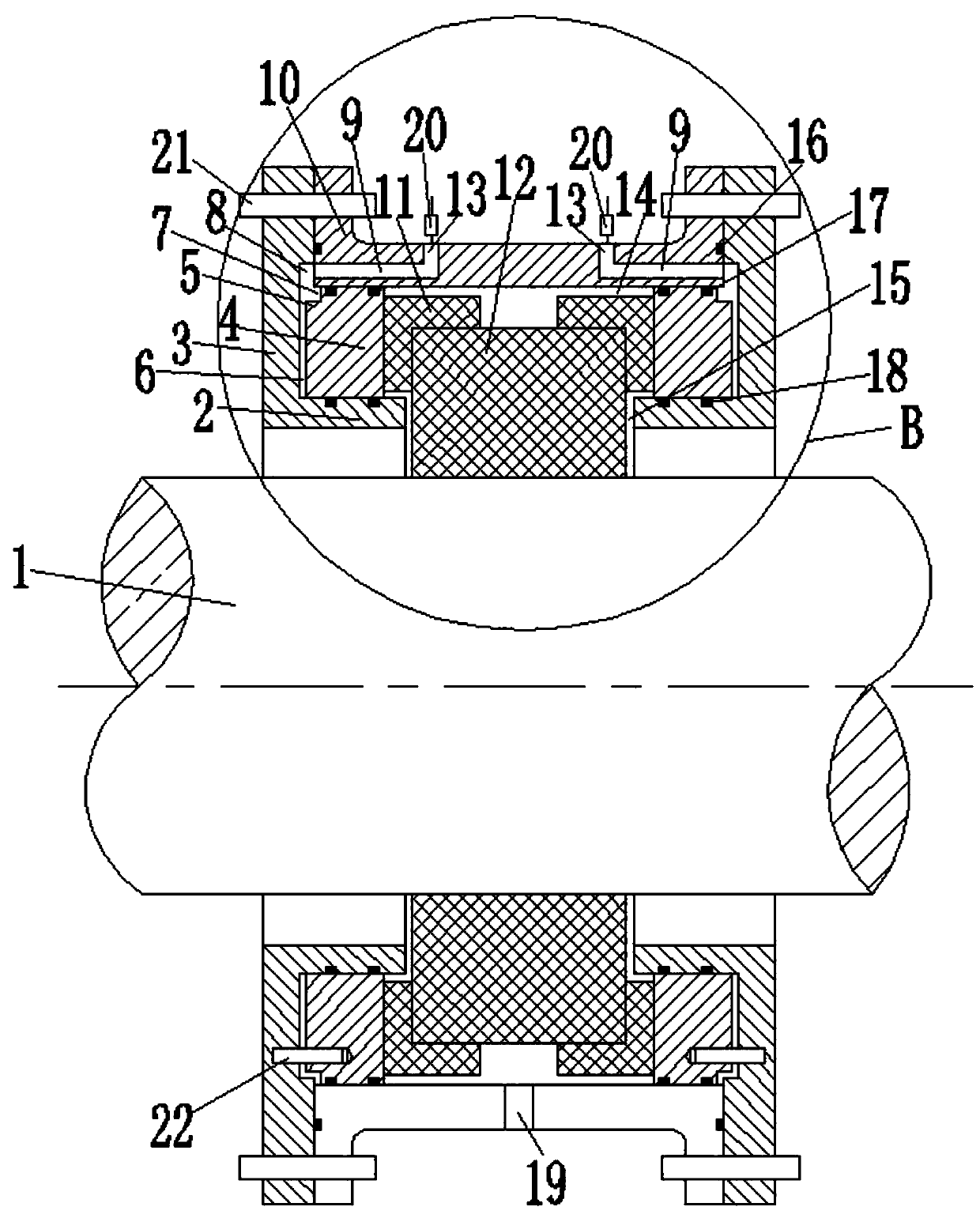

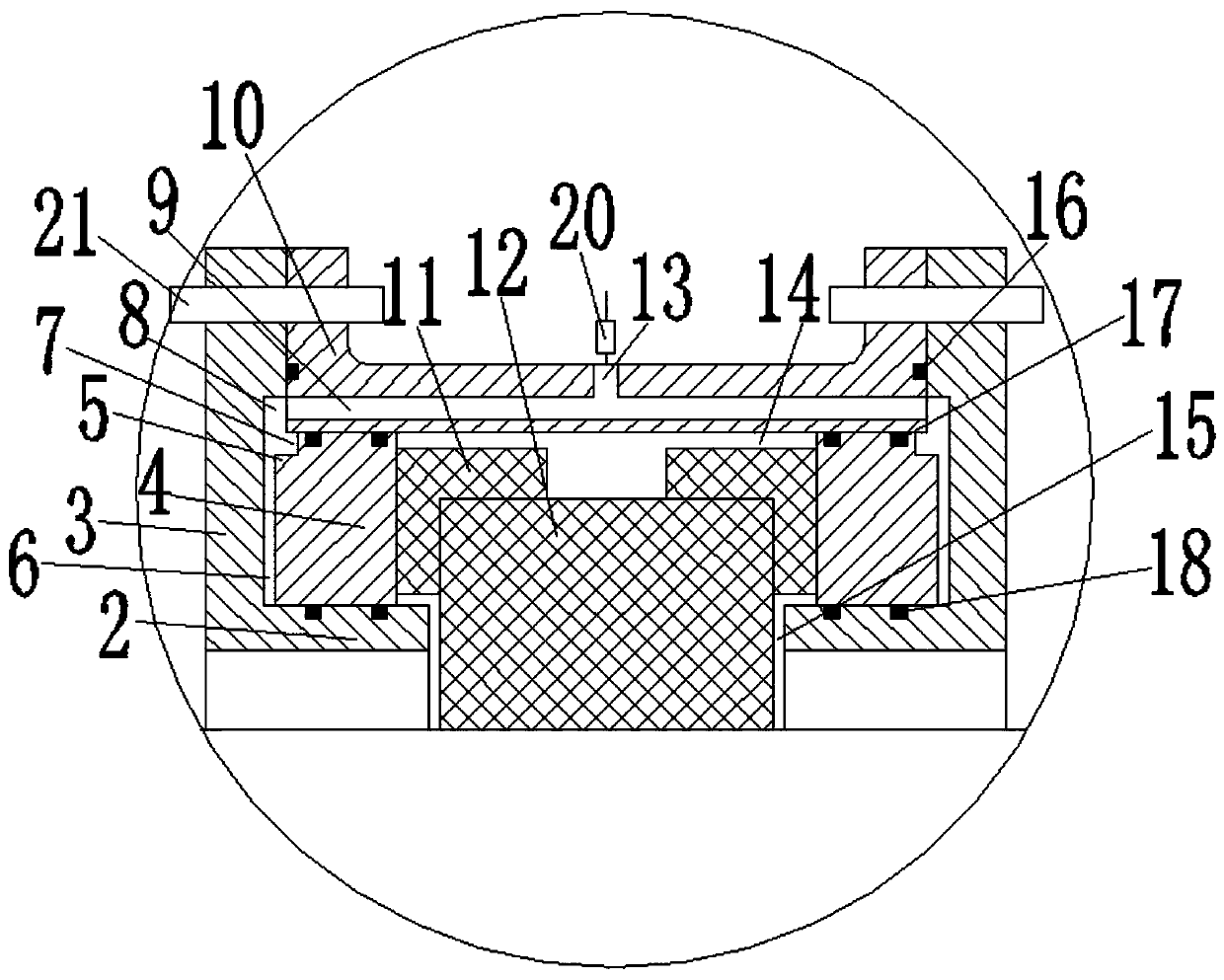

The invention belongs to a torquer magnetic steel assembly device and method. Firstly, an excitation ring is placed in a base, after the lower end face of magnetic steel is coated with a binder, the magnetic steel is placed in an upper cover, the upper cover is mounted on the base, a protruding locating column of the upper cover cooperates with the inner wall of the base, and accurate locating of the magnetic steel in the excitation ring is ensured; and the upper cover and the base are in fastened connection through fastening screws, then a torque screwdriver is adopted for screwing down a force application screw, when the tightening torque exceeds a set value, pressure is not applied to the magnetic steel any more, and it is ensured that the stress of the magnetic steel is consistent. The torquer magnetic steel assembly device and method have the beneficial effects that the pressing force of the magnetic steel can be consistent, the binding quality of the magnetic steel and the binding quality of the excitation ring are consistent, and therefore the assembly quality is improved; the magnetic steel fall-off proportion of an existing assembly method is reduced, the percent of pass of parts is improved, and the production cost is reduced; and the inner side wall of the excitation ring is not damaged under the condition of ensuring magnetic steel accurate locating, and the product surface quality is improved.

Owner:航天科工惯性技术有限公司

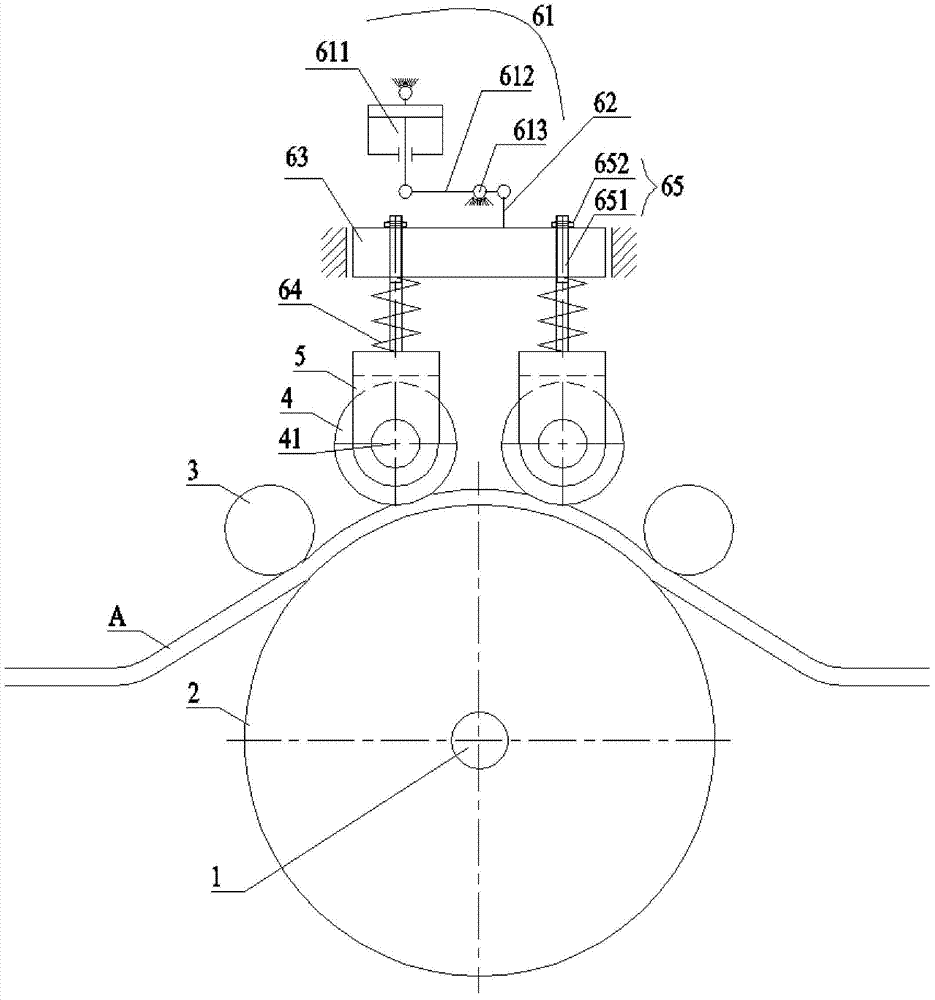

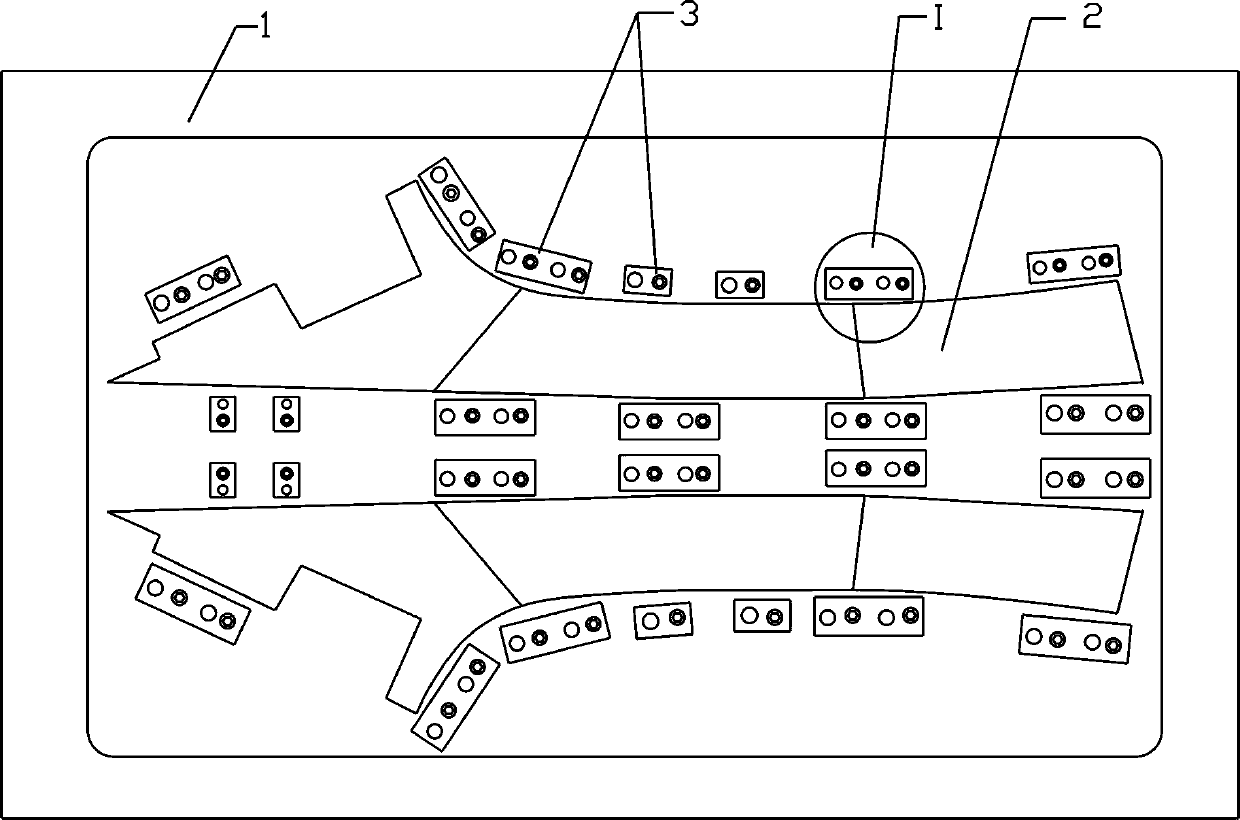

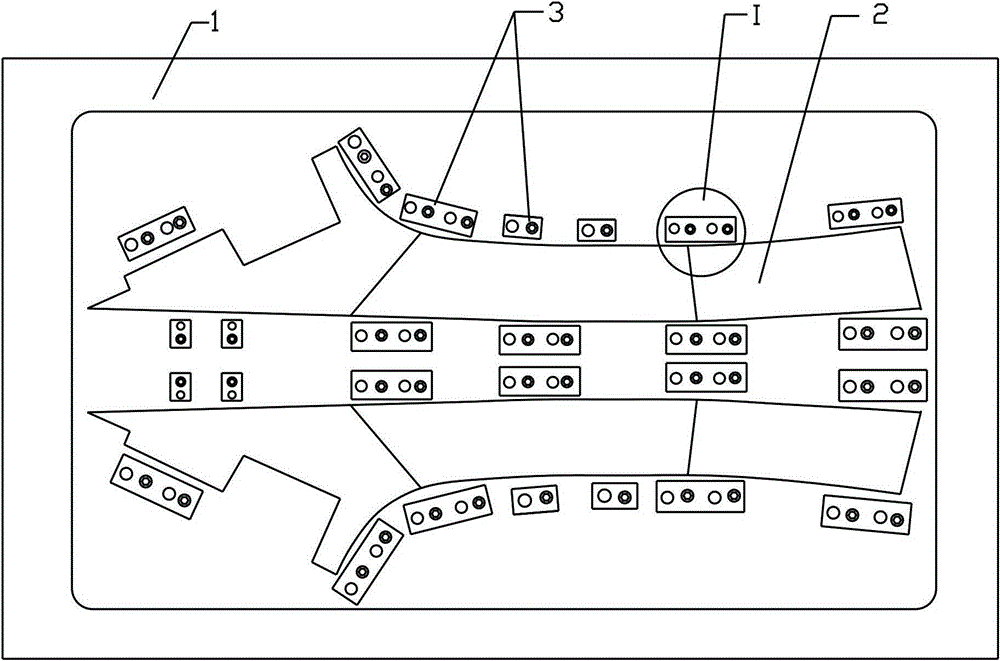

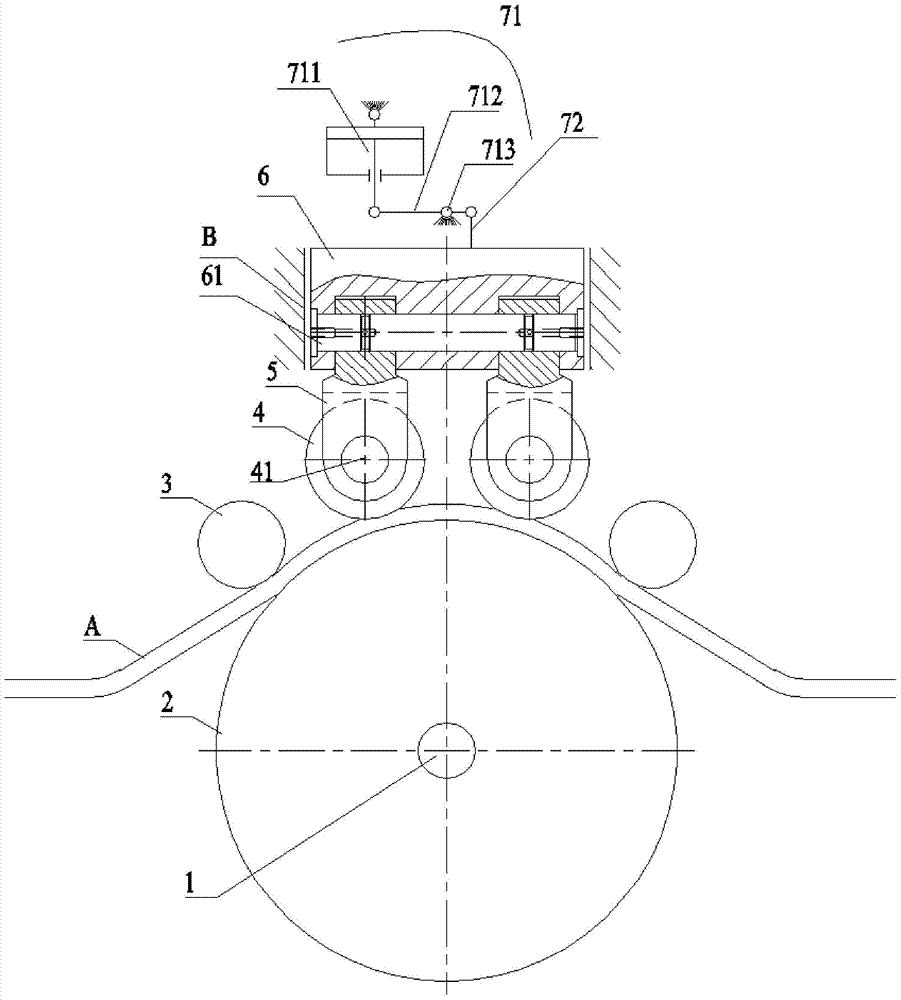

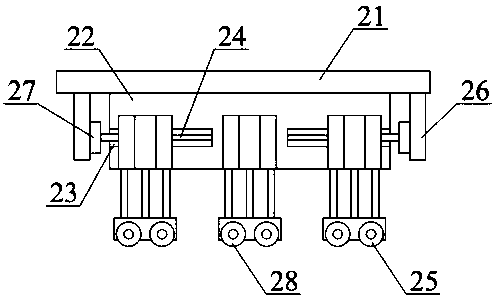

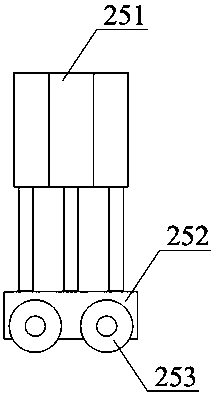

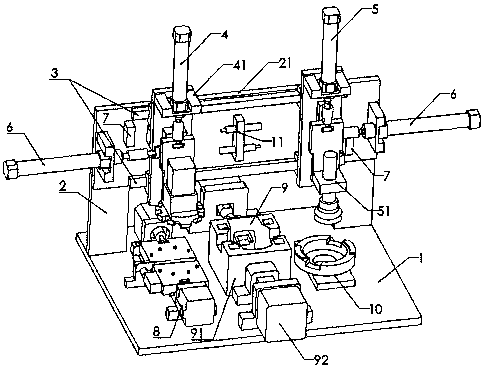

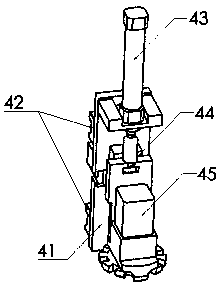

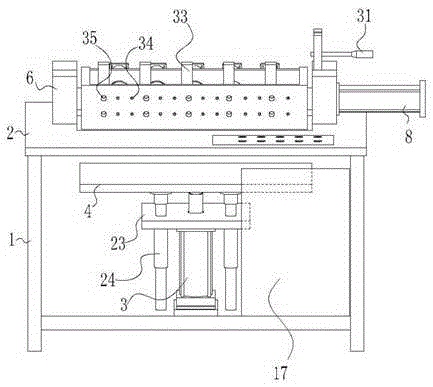

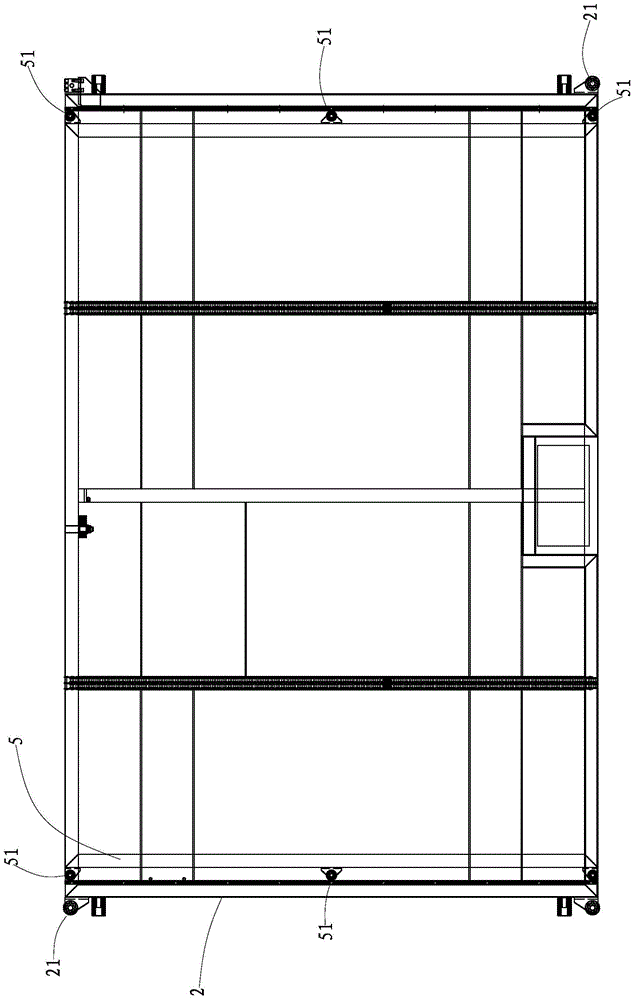

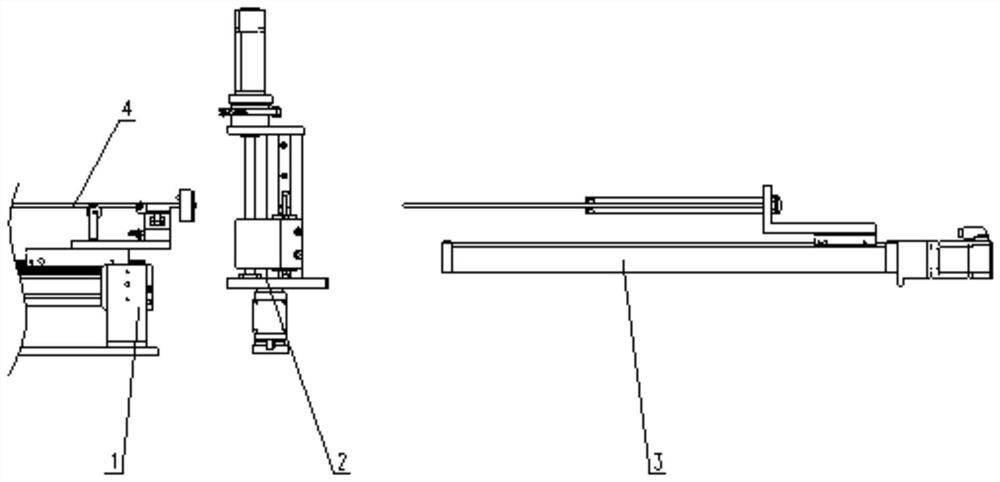

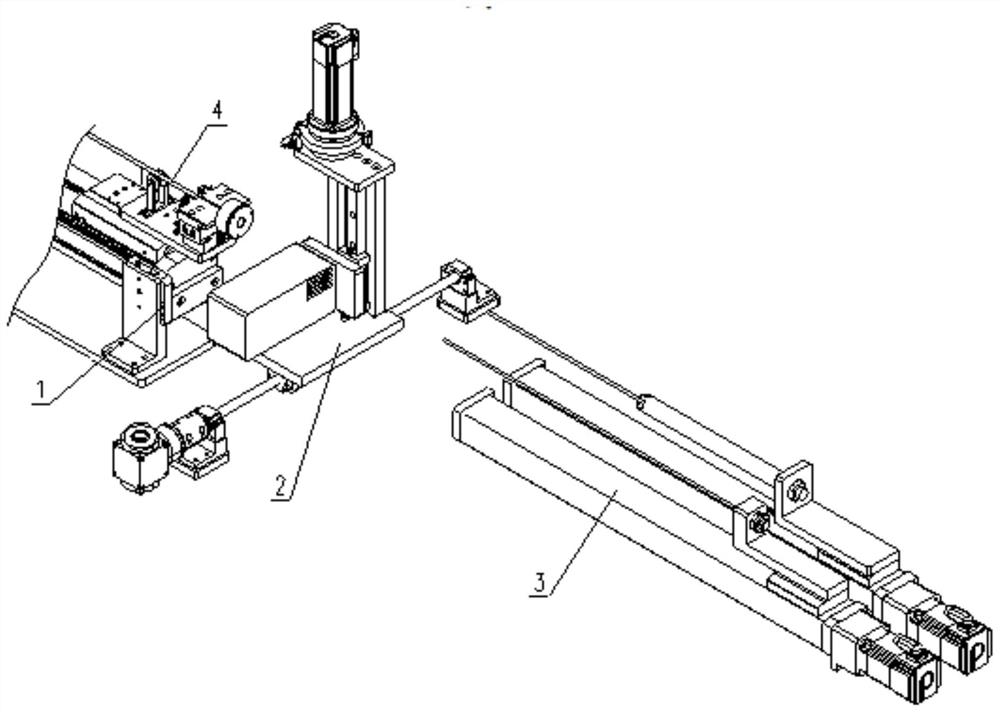

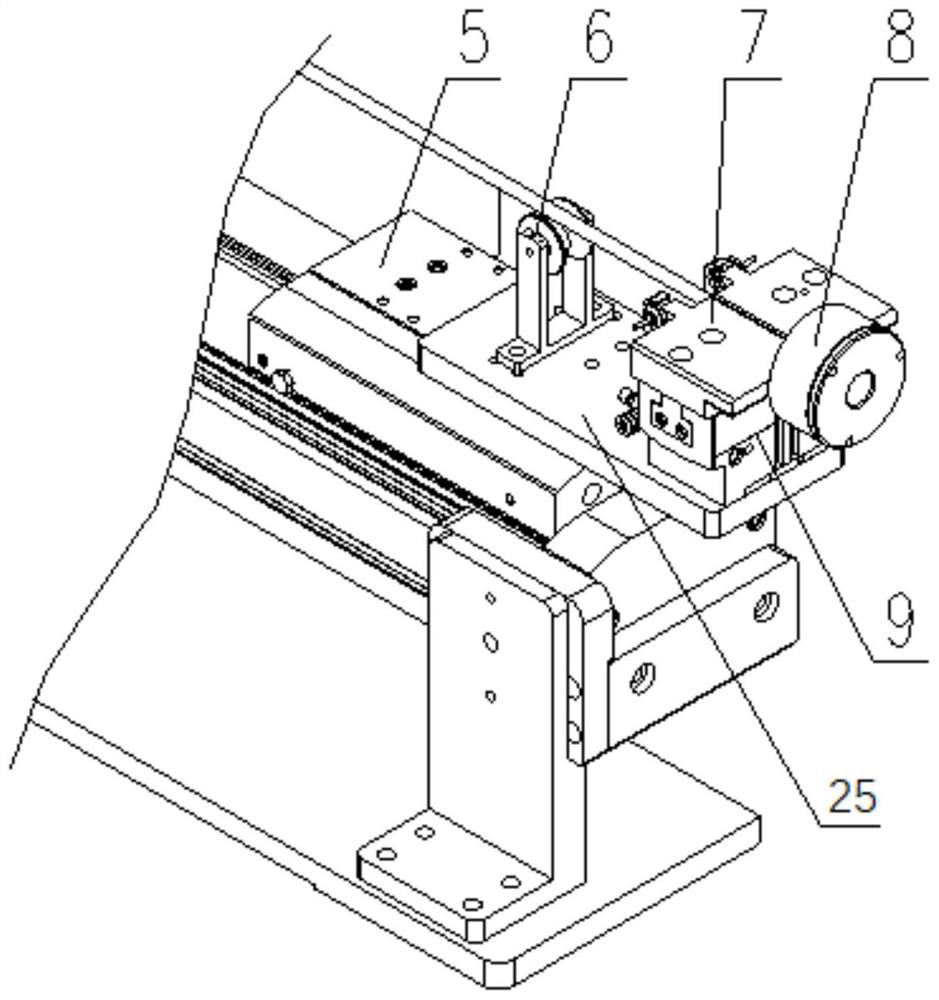

Automatic pressing system for components of tire forming machine

The invention embodiment discloses an automatic pressing system for components of a tire forming machine. A forming drum assembled with a side tire is positioned in the system; firstly, burrs are pressed through a burr roller device; and then, air between the side tire and the forming drum is extruded out through flat pressing of a smooth peripheral roller of a lower pressing roller device, so that the side tire and the forming drum are bonded perfectly, and the isolation is prevented; and meanwhile, the labor intensity of operators is relieved, the consistency of pressing force is guaranteed, and the tire quality is improved. The invention comprises at least one automatic pressing system, wherein the automatic pressing system comprises the lower pressing roller device, the burr roller device, a baseplate and a control device; the lower pressing roller device and the burr roller device are both fixed by the baseplate, and are respectively connected with the control device; the burr roller device is used for pressing the burrs between the side tire and the forming drum, and comprises a burr roller base, a burr roller rail connecting piece, a burr roller and a cylinder; and the lower pressing roller device is used for flattening the side tire and the forming drum, and comprises the peripheral roller, a lower pressing roller guide rail connecting piece and a lead screw connecting piece.

Owner:GUANGZHOU FENGLI RUBBER TIRE +1

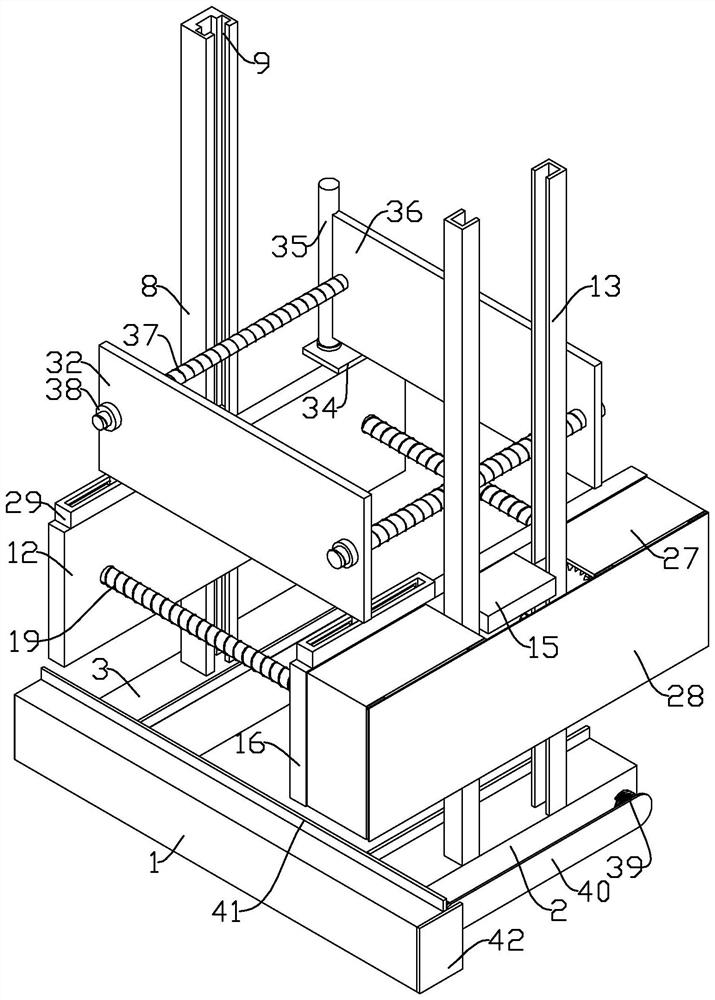

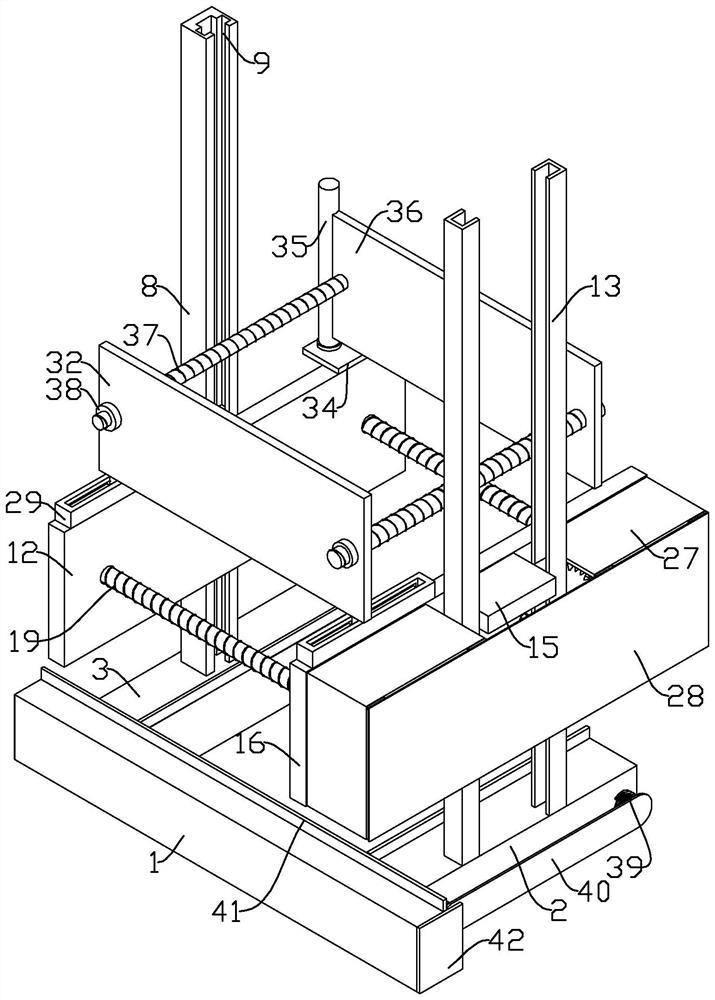

Building formwork reinforcing device

ActiveCN111622500AHeight adjustableEasy to fixForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSlurryScrew thread

The invention relates to the technical field of formwork reinforcing equipment, and in particular relates to a building formwork reinforcing device. The device comprises a base, a front side base anda rear side base, wherein a rear side pressing plate is arranged at the top end of the rear side base, a front side pressing plate is arranged at the top end of the front side base, bearing sleeves are fixedly mounted at two ends of one side of the front side pressing plate correspondingly, first threaded sleeves are fixedly mounted in the bearing sleeves correspondingly, and first fluted discs are fixedly mounted outside the first threaded sleeves on two sides. By arranging the rear side pressing plate, the front side pressing plate, the bearing sleeves, the first threaded sleeves, first screw rods, the first fluted discs, first rotating shafts, a second fluted disc, a third fluted disc, a second rotating shaft, a fourth fluted disc and a grab handle which are matched with one another, the first threaded sleeves on the two sides are the same in rotating speed and consistent in rotating direction in the rotating process, then the stress of the internal formwork is uniform, and thus theproblems of slurry leakage, formwork deviation, formwork explosion and the like caused by large errors in manual assembly and splicing of reinforcing plates are avoided.

Owner:浙江润泰建设有限公司

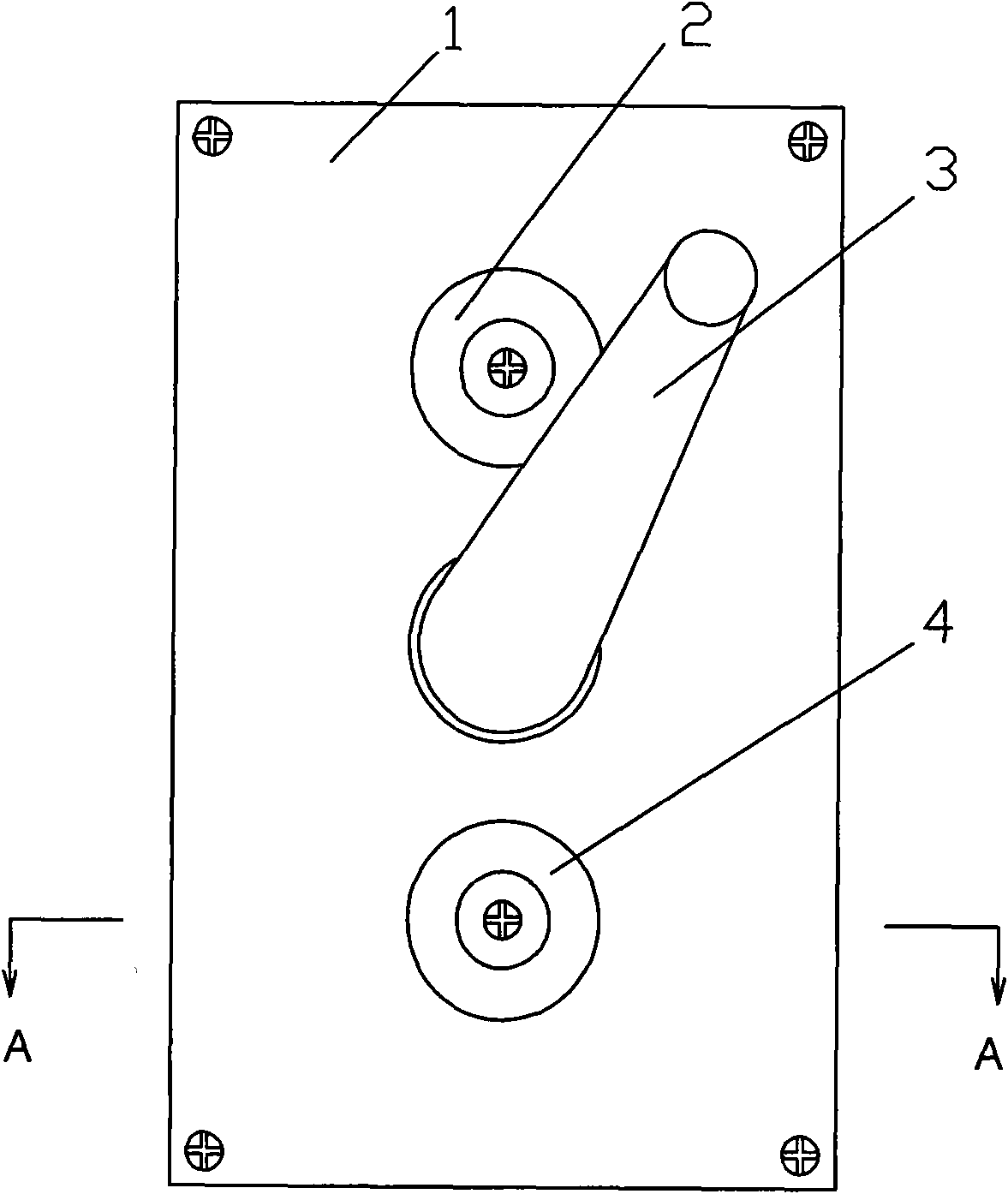

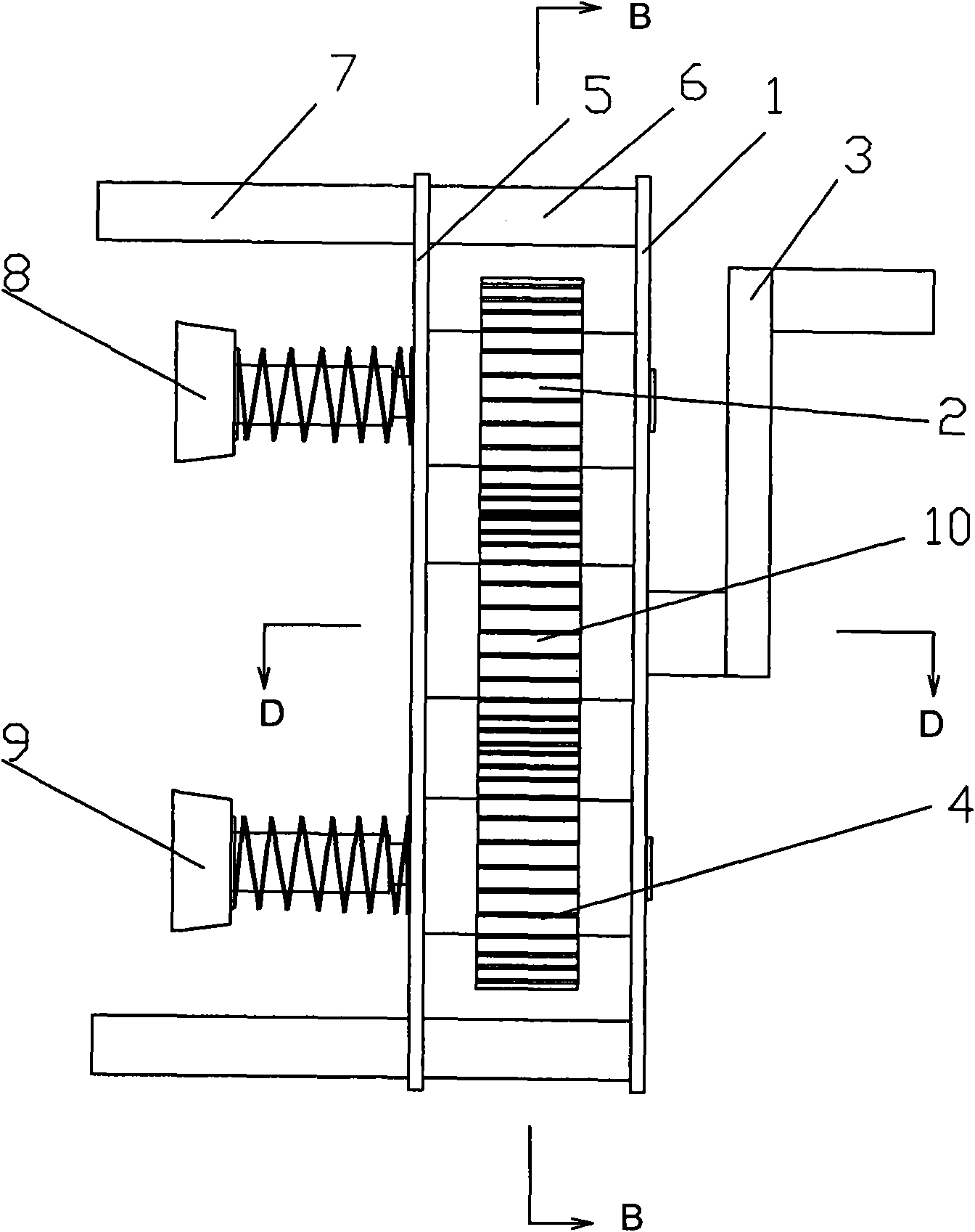

Casting and retreating device for press plate

ActiveCN102055136AEasy to carryFlexible and reliable operationSubstation/switching arrangement detailsEngineeringDepth direction

The invention relates to a casting and retreating device for a press plate, comprising a shell in which a transmission gear, an upper gear and a lower gear are arranged, wherein the upper gear and the lower gear are engaged with the transmission gear, the outer end of a shaft of the transmission gear is provided with a turning handle, the inner ends of shafts of the upper gear and the lower gear are respectively provided with an upper sleeve and a lower sleeve, the distance between the upper sleeve and the lower sleeve is equal to the distance between an upper nut and a lower nut of the pressplate, the upper sleeve and the lower sleeve are provided with wedge-shaped holes which are large at the outside and small at the inside, and convex teeth extending along the depth direction of each hole are arranged on the inner wall of each hole. The casting and retreating device for protecting the press plate is convenient to carry and flexible and reliable to operate when in use.

Owner:XUCHANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

A low pressure injection mold

The invention discloses a low-pressure injection molding mold comprising a fixed mold, a mold core, and a surface material pressing mechanism. The mold core is arranged on the fixed mold. The surface pressing mechanism is composed of a plurality of pressing devices. A plurality of recesses are provided around the mold core. The pressing devices are fixedly arranged in the recesses. The pressing devices are composed of limiting blocks, pins, and elastic elements. The limiting blocks are fixedly arranged on the fixed mold. At least one limiting hole is arranged on each limiting block. The pins and the elastic elements are arranged in the limiting holes. One part of the pin extends out of the limiting hole. The elastic elements are arranged below the pins. The other ends of the elastic elements bear against the fixed mold. The mold has the advantages of simple structure, low cost, high product molding qualification rate, and stable and reliable application.

Owner:CHENGDU AEROSPACE MOLD & PLASTIC CO LTD

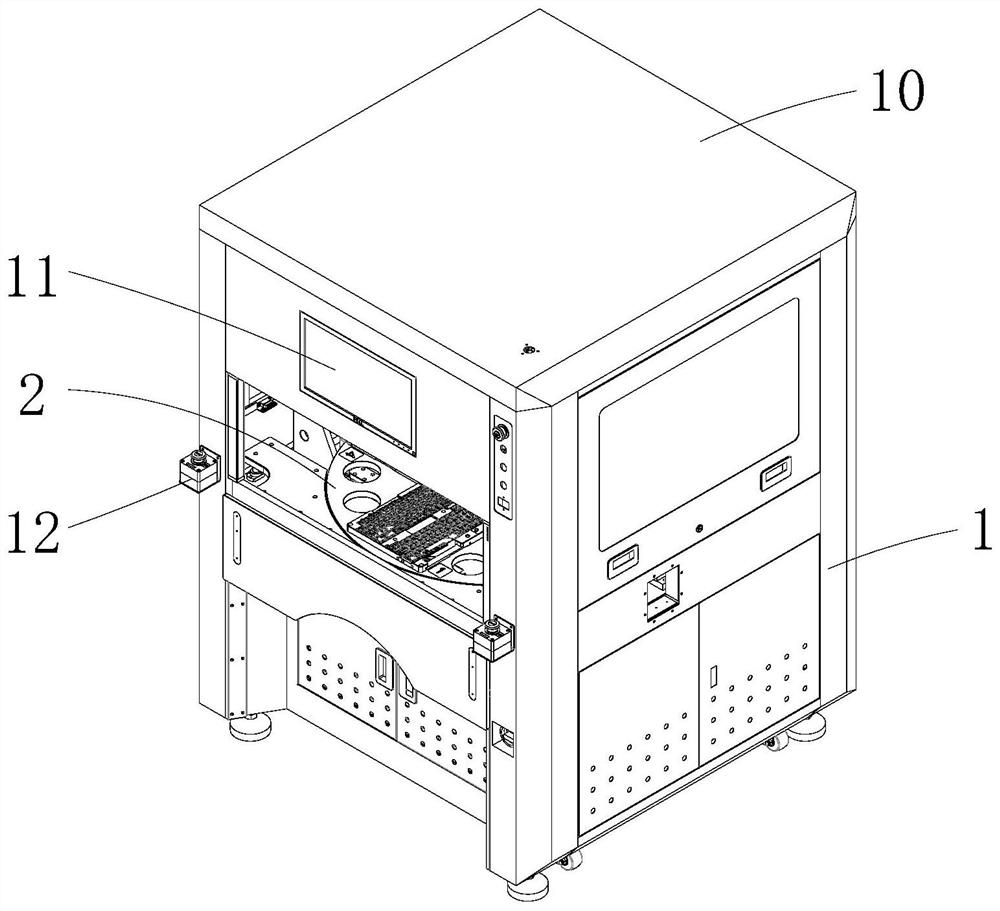

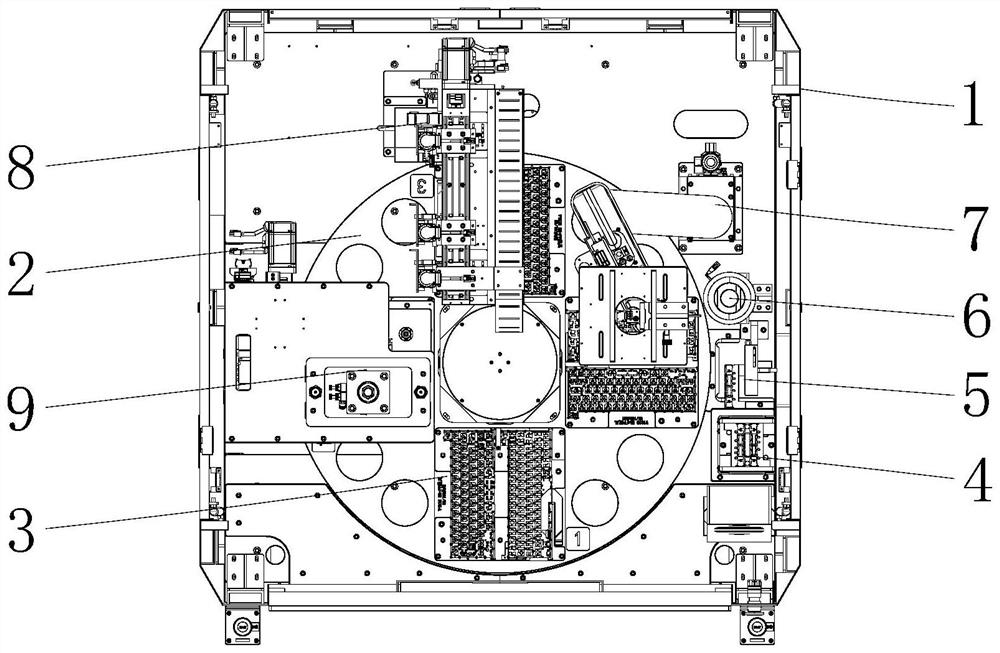

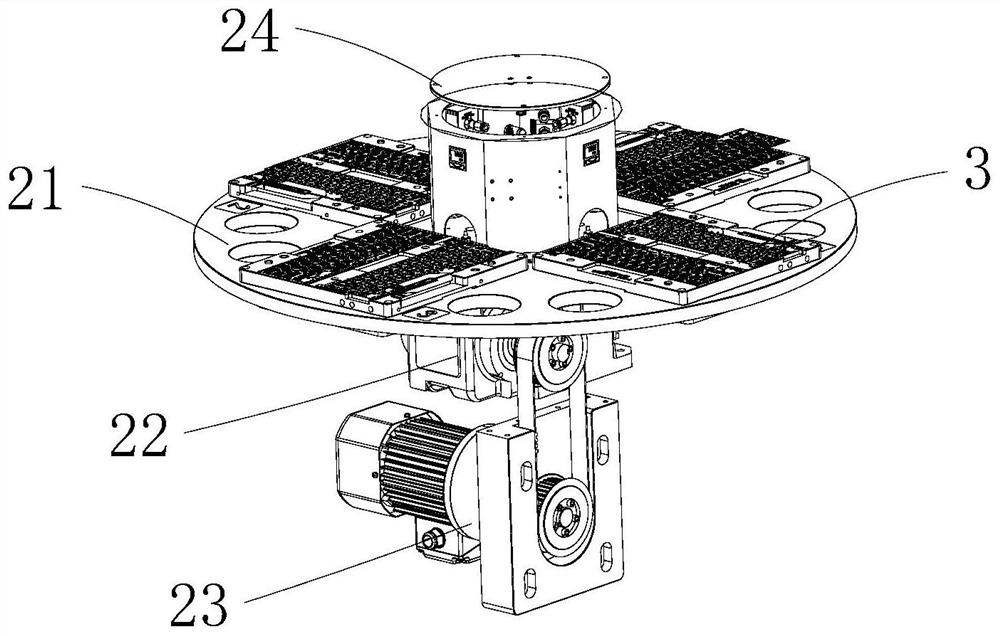

Automatic keyboard laminating equipment

PendingCN113339372AReduce manual labor intensityReduce labor costsMaterial gluingStructural engineeringMechanical engineering

The invention relates to automatic keyboard laminating equipment which comprises a rack, a turntable component is arranged on the rack, a plurality of carriers for placing substrates and circuit wafers are arranged on the turntable component, a pressure-sensitive adhesive bin, a lower film tearing mechanism, a CCD alignment mechanism, a mechanical arm, an upper film tearing mechanism and a transplanting and pressing mechanism are sequentially arranged on the periphery of the turntable component in the anticlockwise direction; and the transplanting and pressing mechanism comprises a supporting base fixed to the rack, an X-direction transplanting module arranged in the middle of the supporting base, a first suction assembly connected with the X-direction transplanting module, a supporting wedge plate arranged at the bottom of the supporting base, a pressing air cylinder arranged at the top of the supporting base and a pressing plate arranged between the pressing air cylinder and the supporting wedge plate. According to the automatic keyboard laminating equipment, the laminating operation of a keyboard can be automatically carried out, and the production efficiency is improved while the manual labor intensity and the cost are reduced; and the attaching positions of the substrates and the circuit wafers are accurate, the pressing force is consistent, and the stability of the quality of a keyboard finished product is guaranteed.

Owner:苏州邦冠自动化设备有限公司

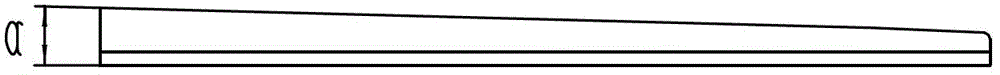

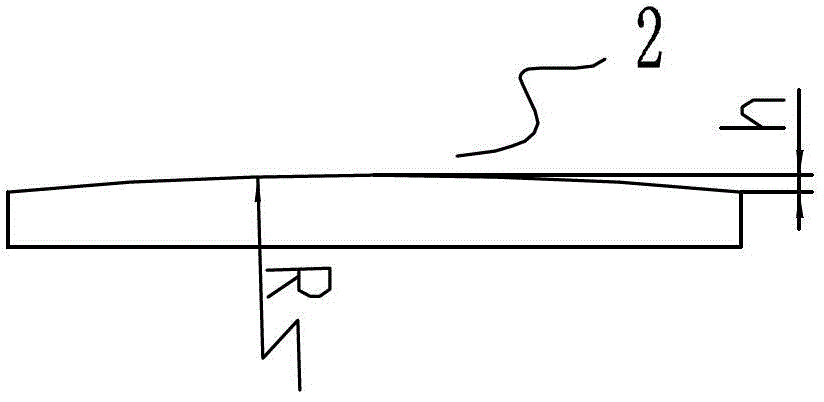

Curved carbon fiber plate clip

ActiveCN103174261BConsistent pressing forceAvoid uneven forceBuilding reinforcementsFiberAngle alpha

Owner:LIUZHOU OVM MASCH CO LTD

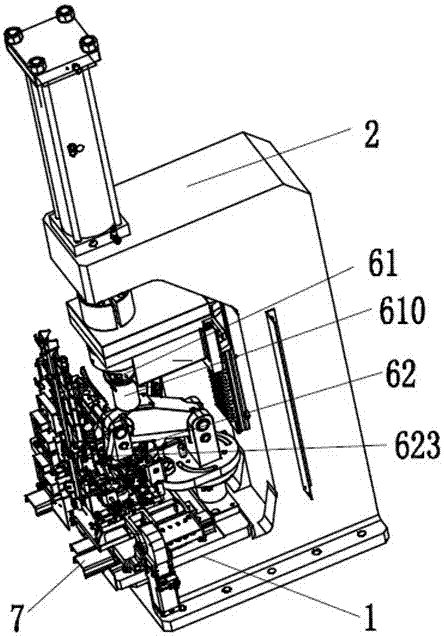

Intelligent riveting equipment and riveting method thereof

ActiveCN104815939BConsistent pressing forceRealize automated productionIt equipmentSurface structure

The invention discloses an intelligent rivet-pressing device and a rivet-pressing method of the intelligent rivet-pressing device. The intelligent rivet-pressing device comprises a first platform, a rack, a feeding and returning mechanism, a to-be-processed part positioning device, a to-be-processed part fixing device and a rivet-pressing mechanism. The rivet-pressing mechanism comprises a first punch mechanism and a second punch mechanism, wherein the first punch mechanism comprises a first punch which can slide axially, the bottom surface of the first punch is of a cambered surface structure, and the first punch mechanism is arranged above the second punch mechanism in a clearance mode and drives the second punch mechanism to work. The second punch mechanism comprises a lever, a U-shaped supporting seat and a second punch. The intelligent rivet-pressing device has the advantages that the function of the rivet pressing can be ingeniously realized through the arrangement of the lever, the pressing force born by the second punch during the whole rivet pressing can be kept consistently due to the arrangement of the cambered surface structure, the production efficiency of the whole device is improved, the labor cost is reduced, the rate of waste is low, and the production automation can be realized.

Owner:苏州泰克诺机电有限公司

A driving wheel anti-slip device of a double-line steel bar hoop bending machine

The invention discloses an anti-skid device for a driving wheel of a double-line steel bar hoop bending machine, which comprises a driving wheel driven by a driving spindle, straightening wheels arranged on both sides of the driving wheel, and at least two pressing wheels arranged on both sides of the center line of the driving wheel. wheel, the lower end of which is connected to the pressing wheel seat of the pressing wheel axle. The top of the pressing wheel seat is arc-shaped, and is movably installed with the connecting plate in the machine base, and also includes a depressing device, and the depressing device is connected with the connecting plate. The present invention adopts the pressing structure of the swingable integral pressing wheel, which can reliably ensure that the pressing wheel automatically follows the change of the size of the steel bar during the process of steel bar processing, and the surface of the processed stirrup is smooth without crush marks and scratches. traces, and improve the quality of mechanized processing steel bars; the invention has the advantages of simple structure, convenient maintenance, stable work, energy saving and low processing cost.

Owner:韶关市华研机械有限公司

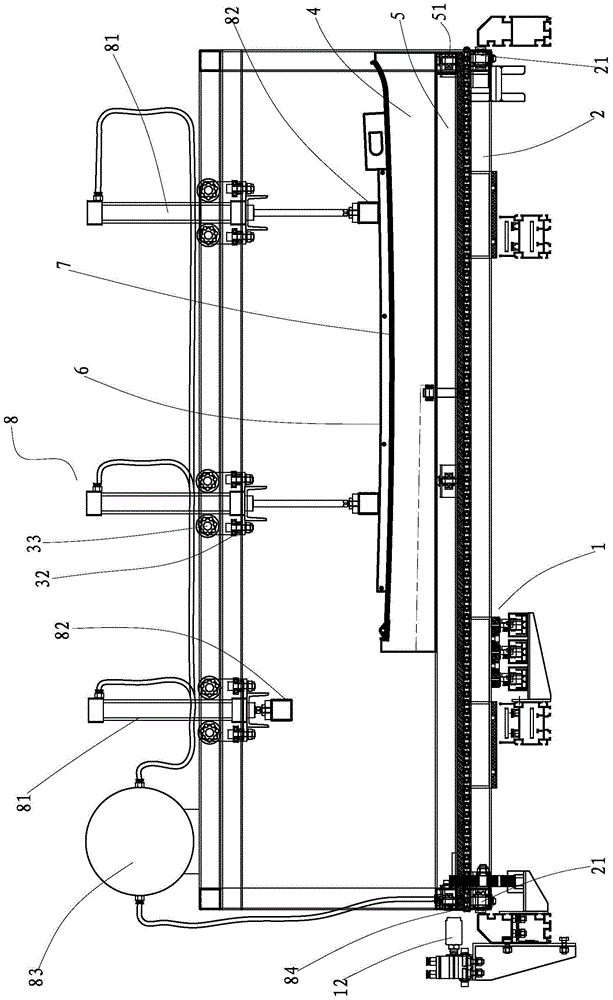

M1 line door seal automatic pressing machine

InactiveCN111572043ASatisfy the pressing operationControl the pressing forceCharacter and pattern recognitionDomestic articlesStructural engineeringElectric control

The invention provides an M1 line door seal automatic pressing machine. The M1 line door seal automatic pressing machine comprises an installation support, a pressing assembly, a visual induction assembly, an electric control cabinet, a PLC, a centering assembly and a supporting plate. According to the M1 line door seal automatic pressing machine, through the arrangement of the centering assemblyand the visual induction assembly, a visual sensor automatically recognizes a door body model, the PLC controls a centering electric push rod to push centering plates to move, so that the distance between the centering plates is matched with the size of the door body model, the pressing size is adjusted according to needs, the pressing operation of door seals of different sizes is met, and the application range of the pressing machine is widened; and a first compression roller assembly and a second compression roller assembly are arranged, an air cylinder pushes a compression roller plate to move downwards, the door seal is subjected to pressing operation through a compression roller, the PLC controls the downward moving distance of the air cylinder, the pressing force of the compression roller on the door seal is kept consistent, the purpose of controlling the pressing force of the door seal is achieved, and the pressing quality of the door seal is improved.

Owner:滁州尚诺自动化设备有限公司

Formwork reinforcement device for building

ActiveCN111622500BHeight adjustableEasy to fixForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSlurryScrew thread

Owner:浙江润泰建设有限公司

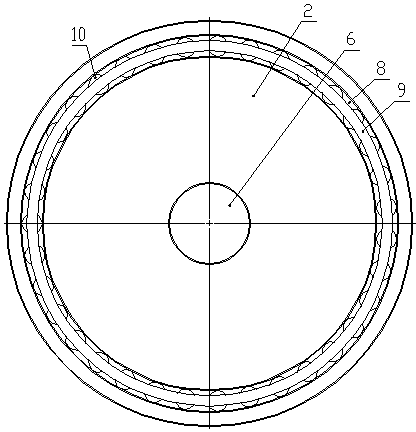

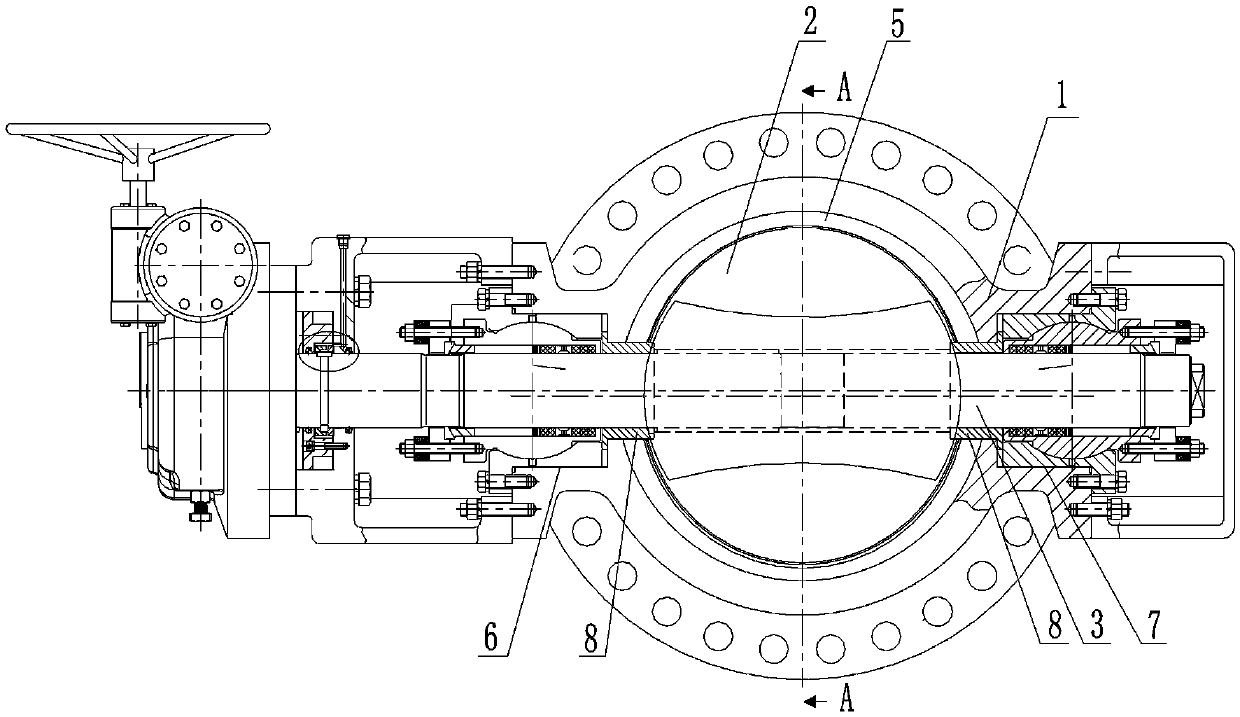

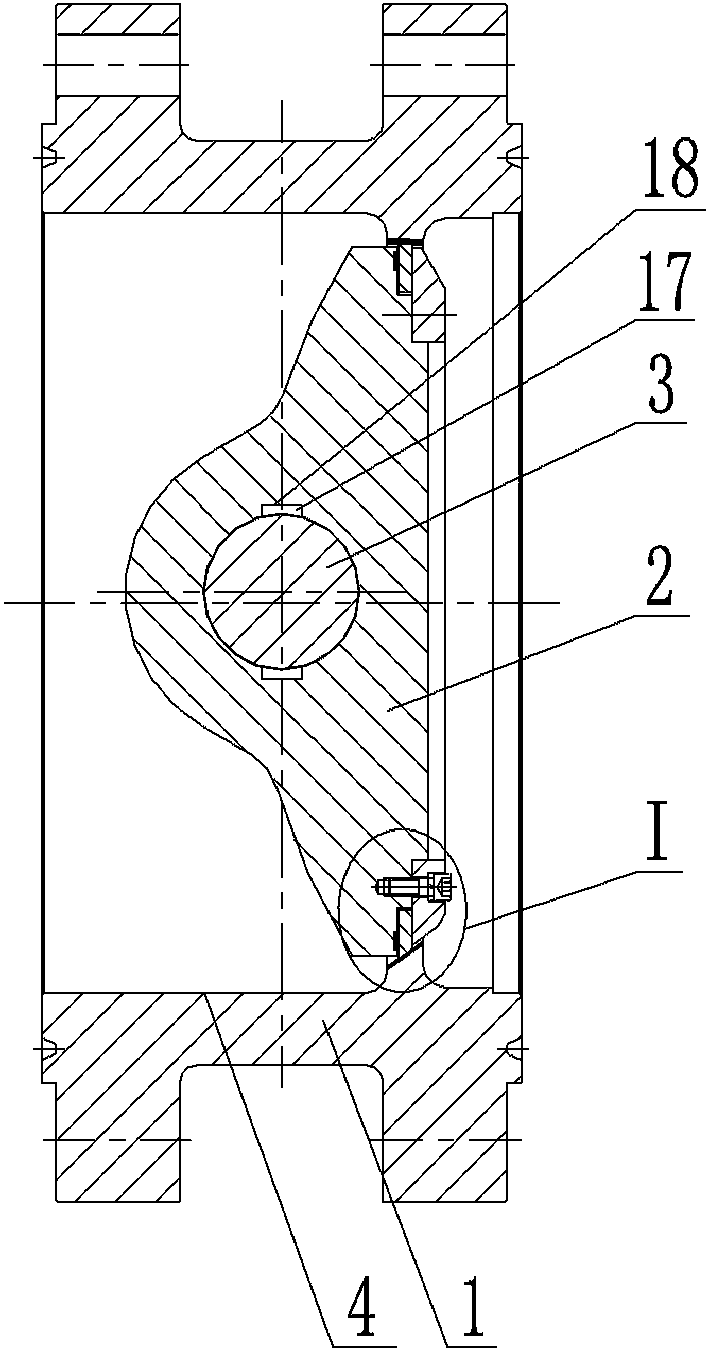

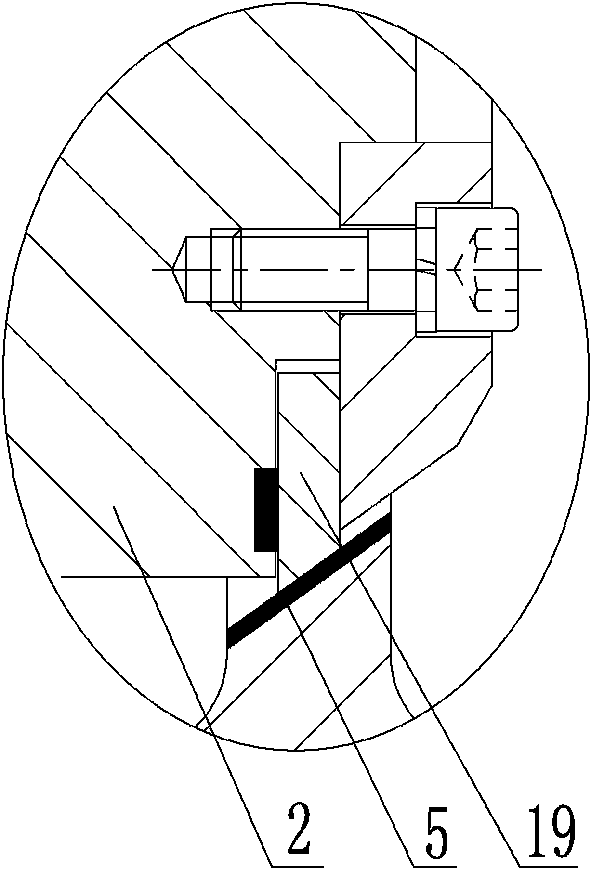

A high-pressure hydrogen-facing butterfly valve for coal-to-hydrogen production

ActiveCN107606188BEliminate rotational flexibilityGuaranteed rotational flexibilitySpindle sealingsLift valveHigh pressure hydrogenEngineering

The invention discloses a coal-to-hydrogen high-pressure butterfly valve in hydrogen service. The coal-to-hydrogen high-pressure butterfly valve comprises a valve body (1), a valve plate (2) and a valve shaft (3). Positioning rings (8) are arranged in small holes of stepped holes. Supporting and sealing assemblies are arranged in large holes of the stepped holes. A spherical groove (15) is formedin a spherical joint outer ring (10). A spherical joint inner ring (9) capable of rotating around the axis of the spherical groove (15) is arranged in the spherical joint outer ring (10). Flat keys (17) arranged in the axial direction are installed on the valve shaft (3). The left end portion and the right end portion of the valve plate (2) are pressed between the two positioning rings (8) in an abutting manner. A seal ring (19) matched with a conical valve seat (5) is installed on the outer ring of the valve plate (2). The coal-to-hydrogen high-pressure butterfly valve has the beneficial effects that operation is reliable, emergent sealing can be conveniently implemented, it is effectively avoided that the valve shaft gets stuck by medium particles, the service life is long, the sealing tightness is ensured and the valve shaft is flexibly started and stopped.

Owner:CHENGDU HUAKE VALVE MFG

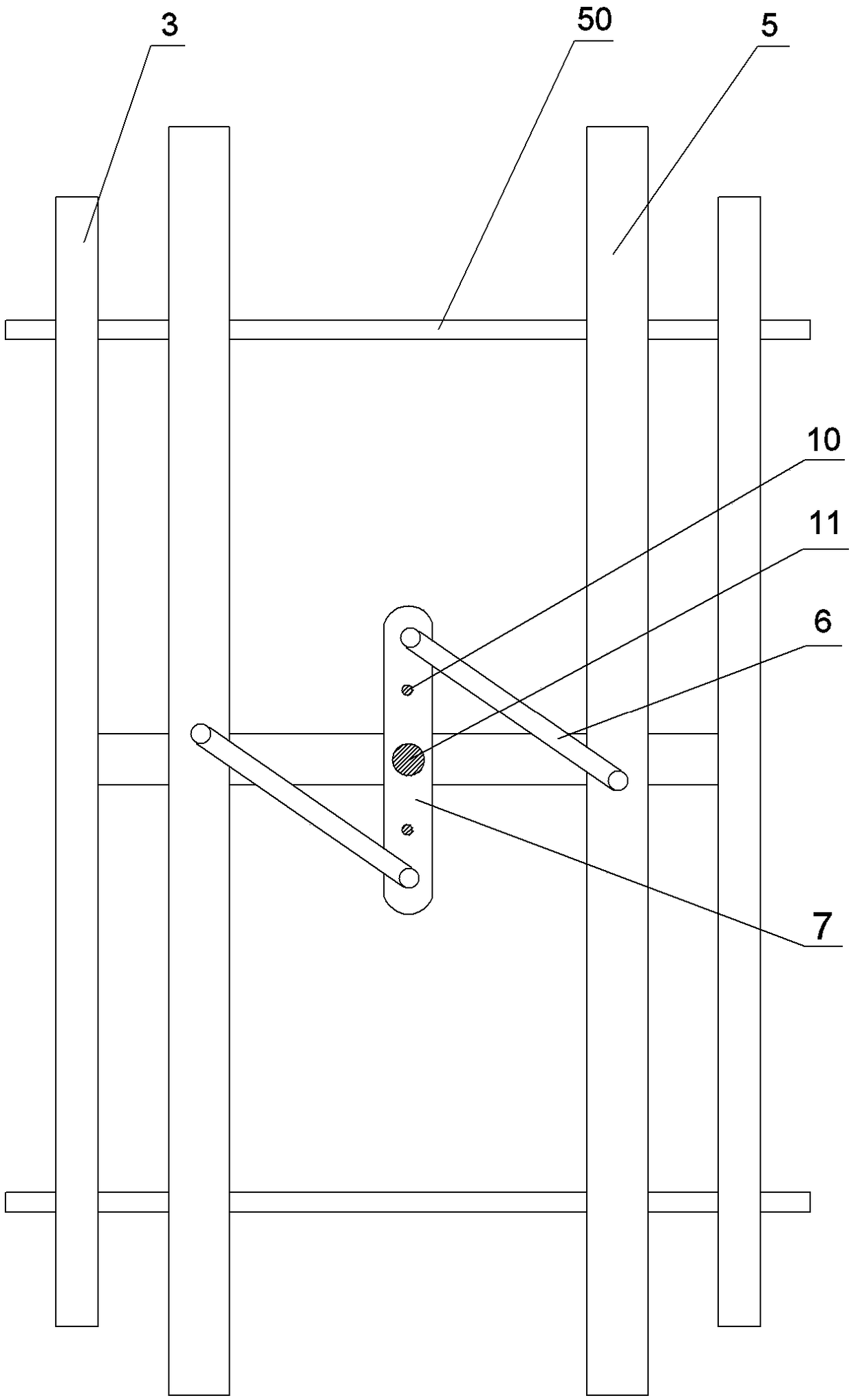

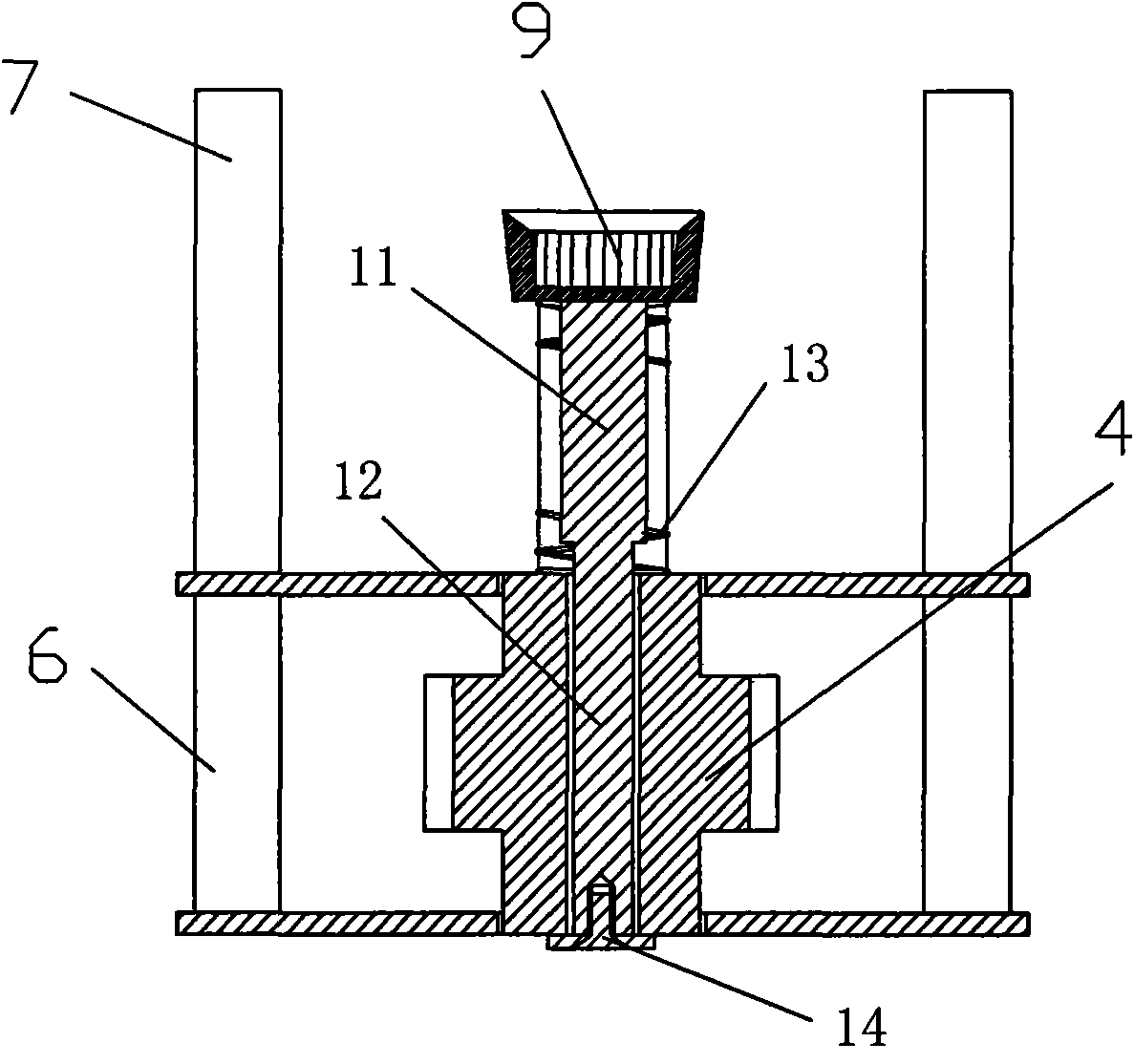

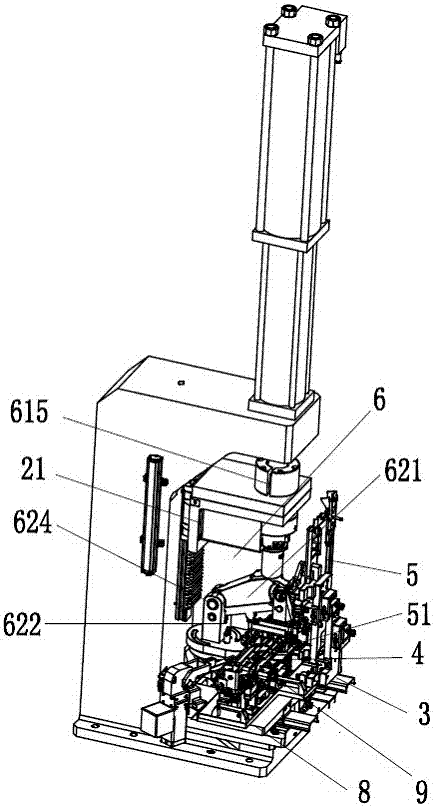

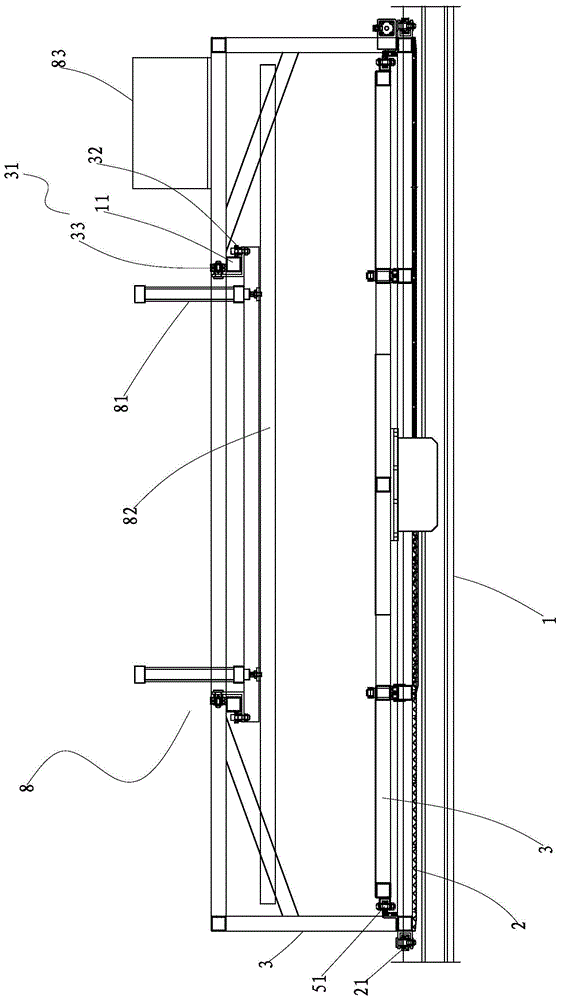

A lens automatic pressing device for a projection unit

InactiveCN106112524BAvoid shakingEasy to operateAssembly machinesVehicle componentsEngineeringPortal frame

The invention provides an automatic lens press-fitting device for a projection unit. The automatic lens press-fitting device comprises a workbench (1), and is characterized in that a portal frame (2) is arranged on the workbench (1), and a cross beam (21) on the portal frame (2) stretches over the workbench (1); guide rails (3) are arranged on the cross beam (21), one end of each guide rail (3) is movably connected with a pressing ring grasping part (4), and the other end of each guide rail (3) is movably connected with a lens grasping part (5); the portions, at the two ends of the guide rails (3), of the cross beam (21) are provided with transverse moving parts (6) connected with the pressing ring grasping part (4) and the lens grasping part (5); and the installing position of a pressing ring positioning mechanism (8) corresponds to that of the pressing ring grasping part (4), and the installing position of a lens positioning mechanism (10) corresponds to that of the lens grasping part (5). By means of the automatic lens press-fitting device, labor intensity is greatly reduced, and production efficiency is improved.

Owner:DANYANG YINUO AUTO PARTS

A superhard material grinding wheel abrasive block and substrate consolidation device and method

ActiveCN103949989BThickness is easy to controlConsistency Guarantee of Thickness UniformityGrinding devicesSuperhard materialAdhesive

A superhard material grinding wheel abrasive block and substrate consolidation device includes a bottom ring, a turntable, an adhesive coating mechanism, an elastic magnetic pressure ring and an electromagnetic ring. The method for bonding the abrasive block of the superhard material grinding wheel to the base includes the following specific steps: (1), installing the grinding wheel base on the turntable and coating the adhesive; (2), positioning and bonding the abrasive block to the grinding wheel base ; (3), curing the adhesive layer between the abrasive block and the grinding wheel substrate. The thickness of the adhesive layer of the present invention is controllable, and the thickness uniformity of the adhesive on the grinding wheel substrate and the grinding wheel block is consistent; the bonding and pressing force of the grinding wheel block is controllable, which improves the bonding efficiency of the abrasive block; the abrasive block and the grinding wheel The consistency of curing strength between substrates is guaranteed, energy is saved and production efficiency is high.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

A torque device magnetic steel assembly device and method

ActiveCN106555796BConsistent pressing forceReduce shedding ratioFastening meansArchitectural engineeringMagnet

The invention belongs to a torquer magnetic steel assembly device and method. Firstly, an excitation ring is placed in a base, after the lower end face of magnetic steel is coated with a binder, the magnetic steel is placed in an upper cover, the upper cover is mounted on the base, a protruding locating column of the upper cover cooperates with the inner wall of the base, and accurate locating of the magnetic steel in the excitation ring is ensured; and the upper cover and the base are in fastened connection through fastening screws, then a torque screwdriver is adopted for screwing down a force application screw, when the tightening torque exceeds a set value, pressure is not applied to the magnetic steel any more, and it is ensured that the stress of the magnetic steel is consistent. The torquer magnetic steel assembly device and method have the beneficial effects that the pressing force of the magnetic steel can be consistent, the binding quality of the magnetic steel and the binding quality of the excitation ring are consistent, and therefore the assembly quality is improved; the magnetic steel fall-off proportion of an existing assembly method is reduced, the percent of pass of parts is improved, and the production cost is reduced; and the inner side wall of the excitation ring is not damaged under the condition of ensuring magnetic steel accurate locating, and the product surface quality is improved.

Owner:航天科工惯性技术有限公司

Casting and retreating device for press plate

InactiveCN102055136BEasy to carryFlexible and reliable operationSubstation/switching arrangement detailsEngineeringDepth direction

The invention relates to a casting and retreating device for a press plate, comprising a shell in which a transmission gear, an upper gear and a lower gear are arranged, wherein the upper gear and the lower gear are engaged with the transmission gear, the outer end of a shaft of the transmission gear is provided with a turning handle, the inner ends of shafts of the upper gear and the lower gear are respectively provided with an upper sleeve and a lower sleeve, the distance between the upper sleeve and the lower sleeve is equal to the distance between an upper nut and a lower nut of the press plate, the upper sleeve and the lower sleeve are provided with wedge-shaped holes which are large at the outside and small at the inside, and convex teeth extending along the depth direction of each hole are arranged on the inner wall of each hole. The casting and retreating device for protecting the press plate is convenient to carry and flexible and reliable to operate when in use.

Owner:XUCHANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

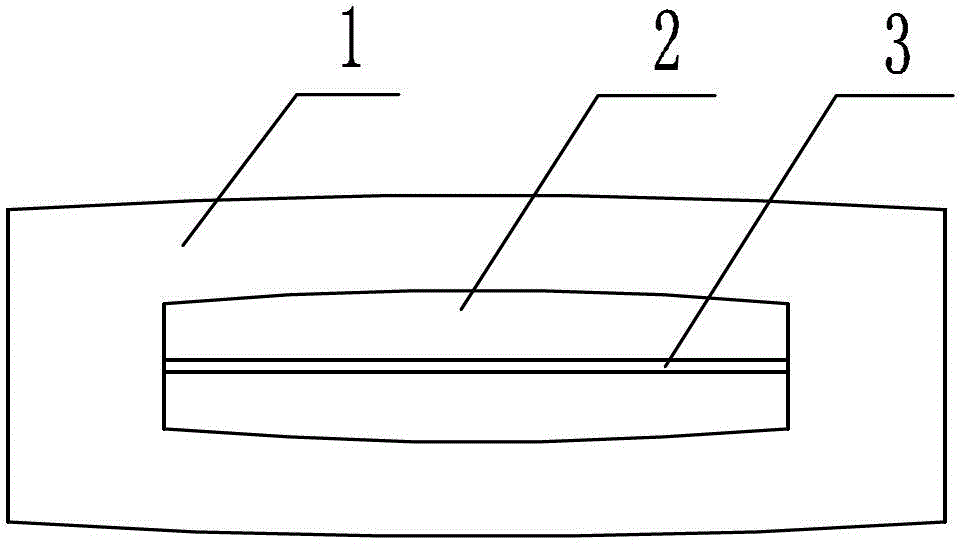

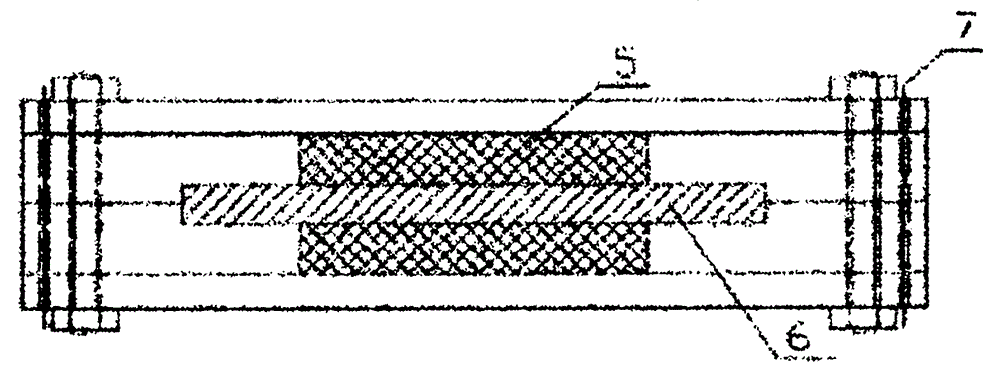

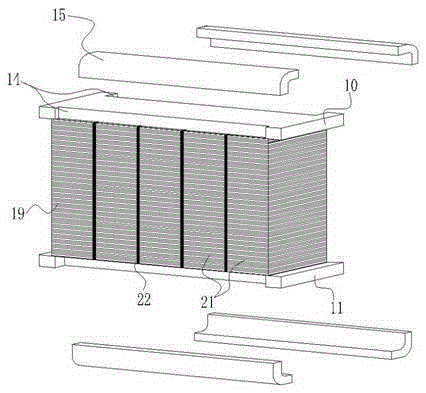

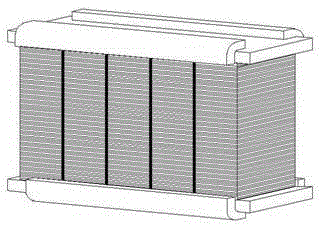

Die for preparing integrated electrode for full-vanadium liquid flow energy storage battery and application thereof

ActiveCN102074710BNo deformationConsistent pressing forceCell electrodesEngineeringUltimate tensile strength

The invention belongs to the field of full-vanadium liquid flow energy storage batteries, particularly relates to a die for preparing an integrated electrode for a full-vanadium liquid flow energy storage battery and application thereof and provides the die for preparing the integrated electrode. The die comprises two die frames with the same shape, size and structure, wherein the die frames are metal flat plates; a groove is arranged on the surface of one side of each plate; holes penetrating through the metal plates are arranged in the middles of the grooves; and groove sides of the two dieframes are oppositely buckled to form the die for preparing the integrated electrode for the full-vanadium liquid flow energy storage battery. The integrated electrode for the full-vanadium liquid flow energy storage battery, which has lower surface resistance, higher combined strength and no deformation, can be prepared by placing an electrode material and a bipolar plate material into the die and carrying out heating, temperature rise, heat preservation, cooling and die stripping.

Owner:DALIAN RONGKE POWER

Copper-aluminum transition junction box for switch in front of meter

ActiveCN114336098AConsistent cutting depthConsistent pressing forceElectrically conductive connectionsPhotovoltaic energy generationEngineeringKnife blades

A meter-front switch copper-aluminum transition junction box disclosed by the present invention comprises a reinforced insulation shell, a connection bolt, a connection nut and a connection sheet, the reinforced insulation shell comprises an upper shell and a lower shell, one end of the connection bolt sequentially passes through the lower shell and the upper shell and then is connected with the connection nut, the other end of the connection bolt tightly presses the lower shell, and the connection sheet is connected with the connection nut. A puncture blade is fixed on the upper shell and / or the lower shell, the puncture blade is arranged between the upper shell and the lower shell, the connecting piece comprises a copper end made of copper and an aluminum end made of aluminum, the aluminum end of the connecting piece is connected with the puncture blade, and the copper end of the connecting piece extends out of the reinforced insulating shell. The invention provides a copper-aluminum transition junction box for a meter-front switch. The copper-aluminum transition junction box can solve the problem that copper-aluminum joints of the meter-front switch of a user meter box are easy to burn out due to different materials of drop wires (aluminum) and binding posts (copper).

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO +2

An adjustable pressure double-sided compression sealing device

ActiveCN109882593BConsistent pressing forceImprove sealingEngine sealsStructural engineeringIndustrial engineering

The invention discloses an adjustable pressure double-sided pressure sealing device in the technical field of grain and feed processing equipment. The sealing device comprises a rotating shaft and twosealing covers. Each sealing cover comprises an annular cover body and a flange ring. An elastic part fixed to the periphery of the rotating shaft is arranged between the two flange rings. The two sides of the elastic part are fixedly provided with dynamic sealing rings, and the peripheries of the flange rings are provided with static sealing rings. A sealing seat is arranged between the two annular cover bodies. Pressing assemblies for driving the static sealing rings to axially move are arranged on the static sealing rings and comprise inlets, wherein the inlets are formed in the sealing seat and used for introducing compressed air or hydraulic oil. A flowing channel communicating with the inlets is formed in the sealing seat. Annular grooves communicating with the flowing channel are formed in the annular cover bodies. Annular flanges are arranged on the static sealing rings. The outer diameters of the annular flanges are smaller than the outer diameters of the static sealing rings. An annular channel communicating with the annular grooves is formed between the peripheries of the annular flanges and the static sealing rings. The adjustable pressure double-sided pressure sealingdevice has the advantages of adjusting the pressing force and improving the sealing effect.

Owner:FAMSUN CO LTD

Two-point flexible hold-down fixtures at different heights

ActiveCN106799603BReduce distortionConsistent pressing forceWork clamping meansPositioning apparatusEngineeringHinge angle

The invention relates to a two-point flexible pressing clamp at different heights. The two-point flexible pressing clamp is characterized by comprising a basal body and a fixed base connected on the basal body, wherein pressure plates are mounted at the two sides of the upper end of the fixed base; the lower ends of the pressure plates are rotatably connected with the fixed base; pressure heads are arranged at the upper ends of the pressure plates; a hinge is arranged between the pressure plates at the two sides; the lower end of the hinge is rotatably connected with the upper end of a drawbar; the lower end of the drawbar penetrates through the fixed base and the basal body; the lower end of the drawbar is connected with a thrust force source; a pressure plate connecting pin is arranged on the hinge in a sliding mode; and the pressure plate connecting pin is connected with pressure plates at the left side and the right side. The two-point flexible pressing clamp at different heights can solve the problem that two points in two planes at different heights are simultaneously pressed and are consistent in pressing force in a limited space as a result of casting errors.

Owner:WUXI BEST PRECISION MACHINERY

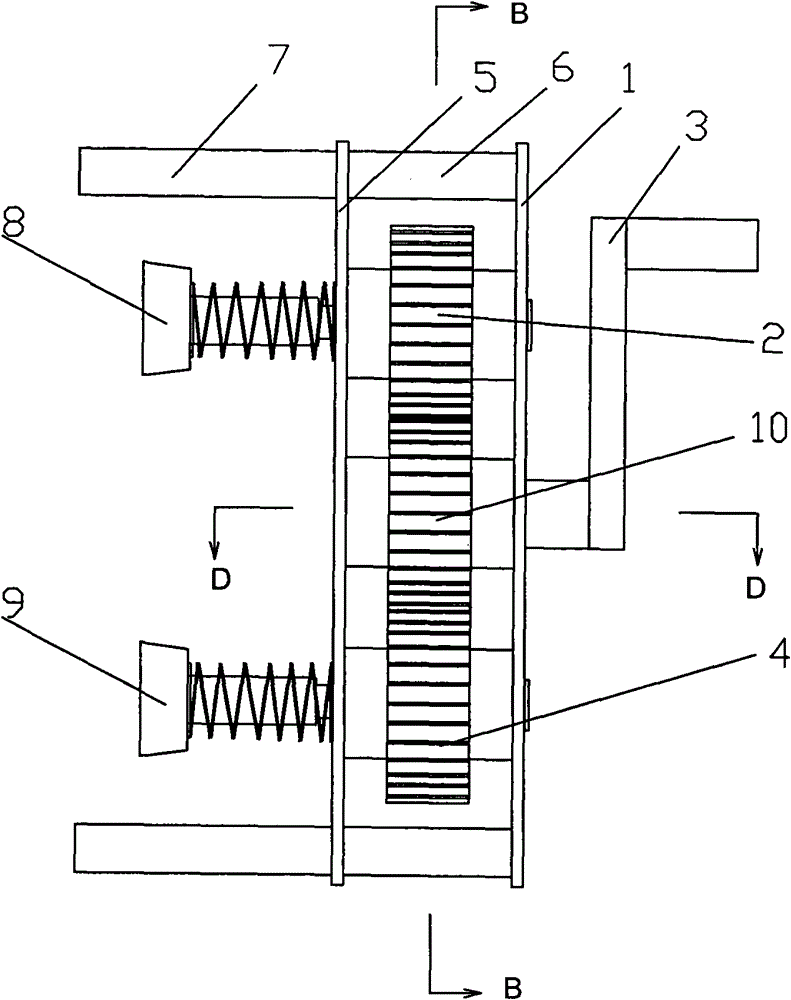

Lamination device and lamination method for reactor iron core

ActiveCN103280308BEnsure consistencyReduce air gap errorInductances/transformers/magnets manufactureEngineeringVertical cylinder

Owner:襄阳中车电机技术有限公司 +1

A car door gluing and bonding tooling fixture used on an automobile door gluing production line

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

Automatic spring tubing device and system

PendingCN114496324AEasy to installConsistent pressing forceMeasurement devicesNuclear energy generationStructural engineeringMechanical engineering

The invention discloses an automatic spring tubing device and an automatic spring tubing system comprising the automatic spring tubing device, the automatic spring tubing device comprises a tubing mechanism, a storage mechanism and a pushing mechanism, the diameter of the outer ring of a compression spring is larger than the inner diameter of a cladding tube, and the pushing mechanism comprises a push rod assembly and a measuring assembly. The measuring assembly comprises a length measuring rod, the length measuring rod is used for measuring the first distance between the inlet end of the cladding tube and a core block in the cladding tube, the push rod assembly comprises a push rod, and the push rod is used for pushing one compression spring stored in the storage mechanism into the cladding tube after the length measuring rod measures the compression spring and making the compression spring located at the target position in the cladding tube. The length of the compression spring is set as a first length, the distance between the compression spring at the target position and the inlet end of the cladding tube is a second distance, and the second distance is equal to the difference value between the first distance and the first length. According to the device, the consistency of the pressing force of the springs in different cladding pipes on the core block can be ensured.

Owner:CHINA NUCLEAR POWER ENG CO LTD

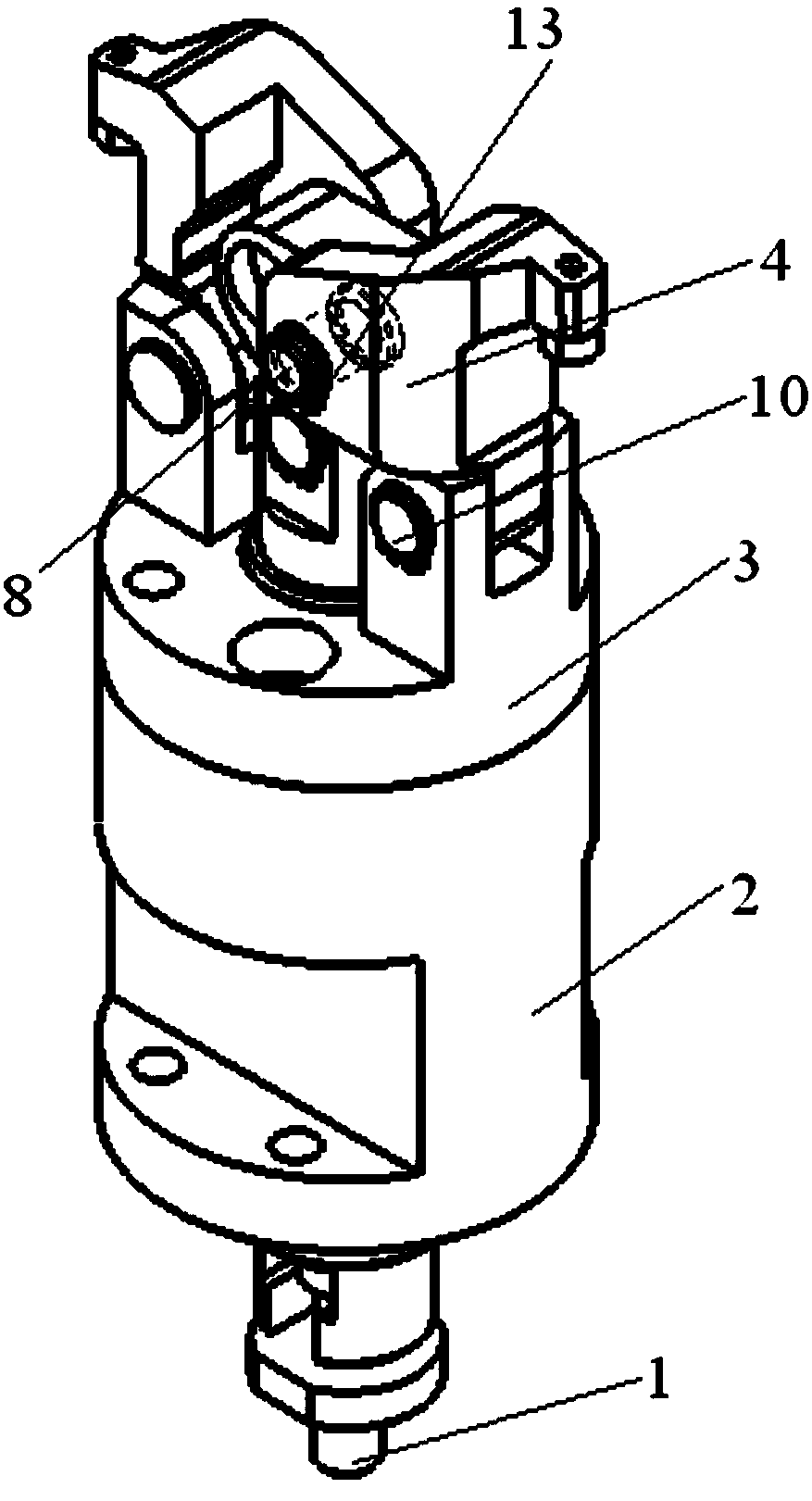

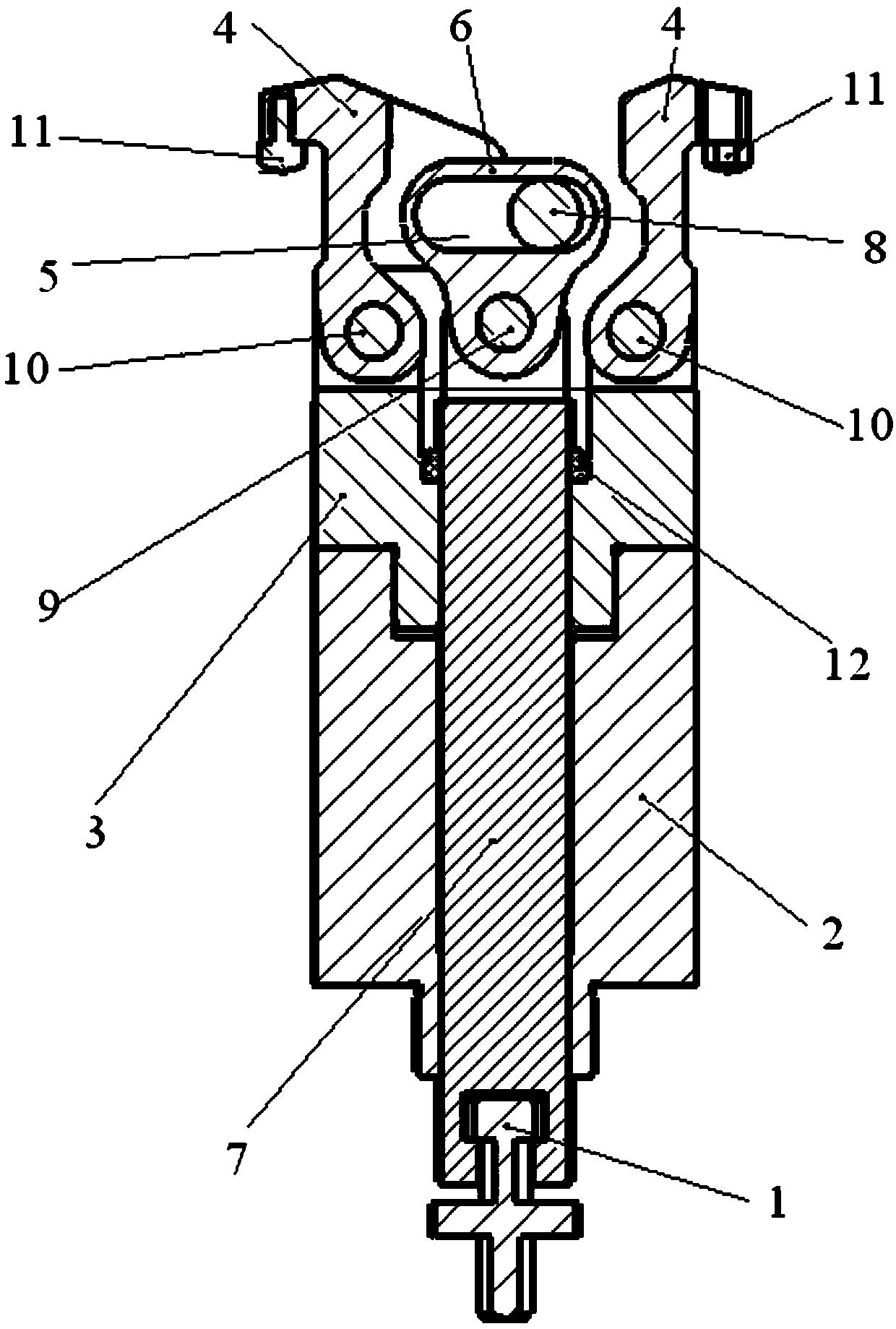

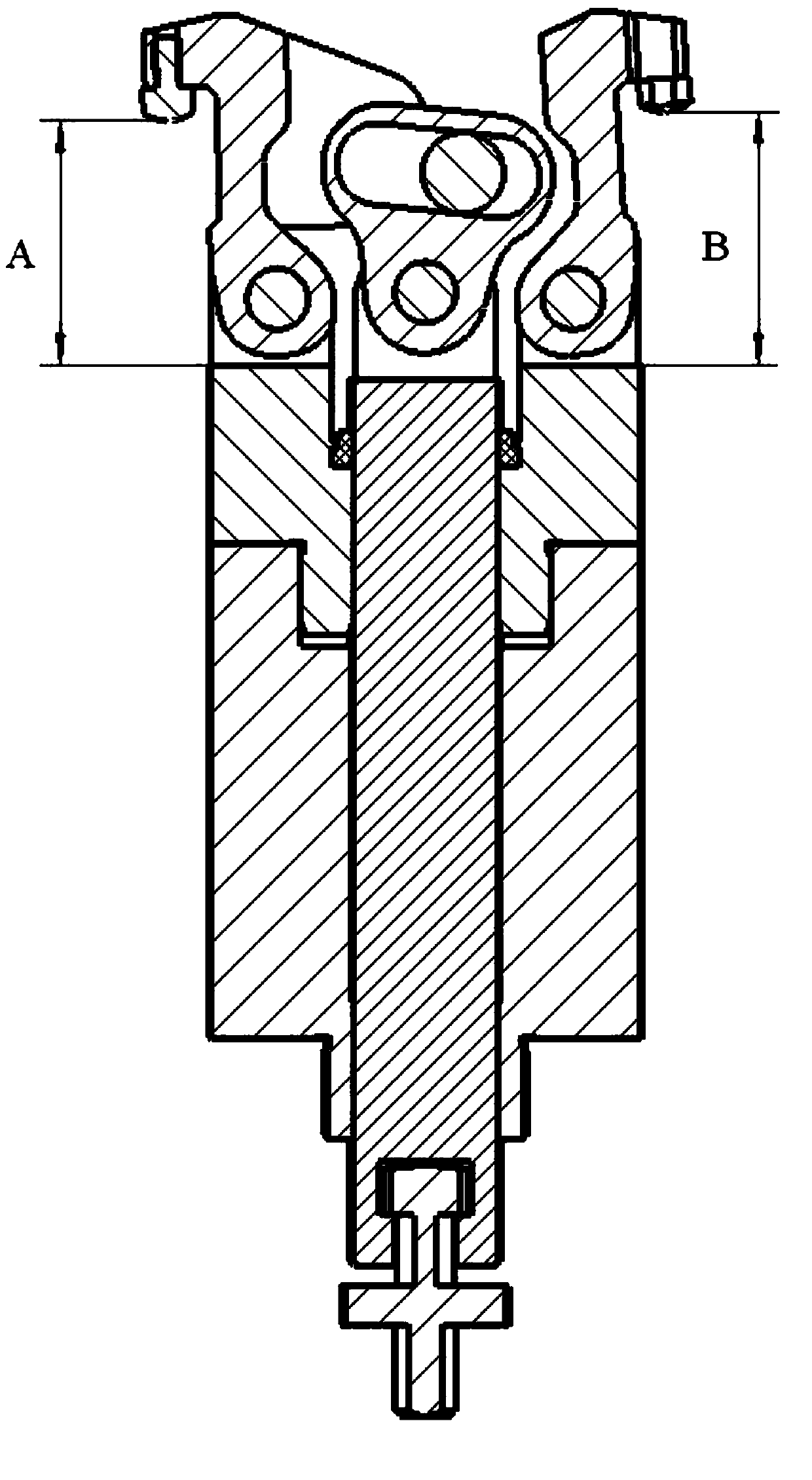

Integral type electrical park brake (EPB) driving device of parking brake

PendingCN109849886AMeeting parking brake needsReasonable structureBraking action transmissionParking brakeBrake pad

The invention discloses an integral type electrical park brake (EPB) driving device of parking brake. The integral type EPB driving device comprises a rotating shaft and a driving assembly for drivingthe rotating shaft to rotate; two synchronous worms are arranged on the rotating shaft, the synchronous worms can apply acting force on two corresponding brake pistons through corresponding transmission assemblies, the brake pistons are arranged in parallel to each other, the force-bearing surfaces of the brake pistons move facing brake pads, acting force of spring piece clips fixedly connected with the brake pads are overcome, and the brake pads are pressed on the surfaces of brake discs; and when parking is released, the transmission assemblies move in the direction back on to the brake pads, the brake pads move backwards under counter-acting force of the spring piece clips, and the brake pistons are pushed to move backward synchronously. The integral type EPB driving device of the parking brake is characterized in that the structure is reasonable, the design is novel, the two brake pistons are synchronously pressed on the brake pads, and reduplicated parking braking force can be generated, so that requirements of the parking brake can be met; and meanwhile, the device is compact in structure, small in size and convenient in installation and debugging, the control response is quick, and maintenance of a vehicle is convenient.

Owner:KUNTAI VEHICLE SYST CHANGZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com