A driving wheel anti-slip device of a double-line steel bar hoop bending machine

A technology of anti-skid device and driving wheel, which is applied in the field of steel bar processing equipment, can solve the problems that integral pressure wheels cannot be adapted at the same time, cannot solve the problem of slippage, and support bearing damage, etc., and achieves simple structure, low processing cost and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

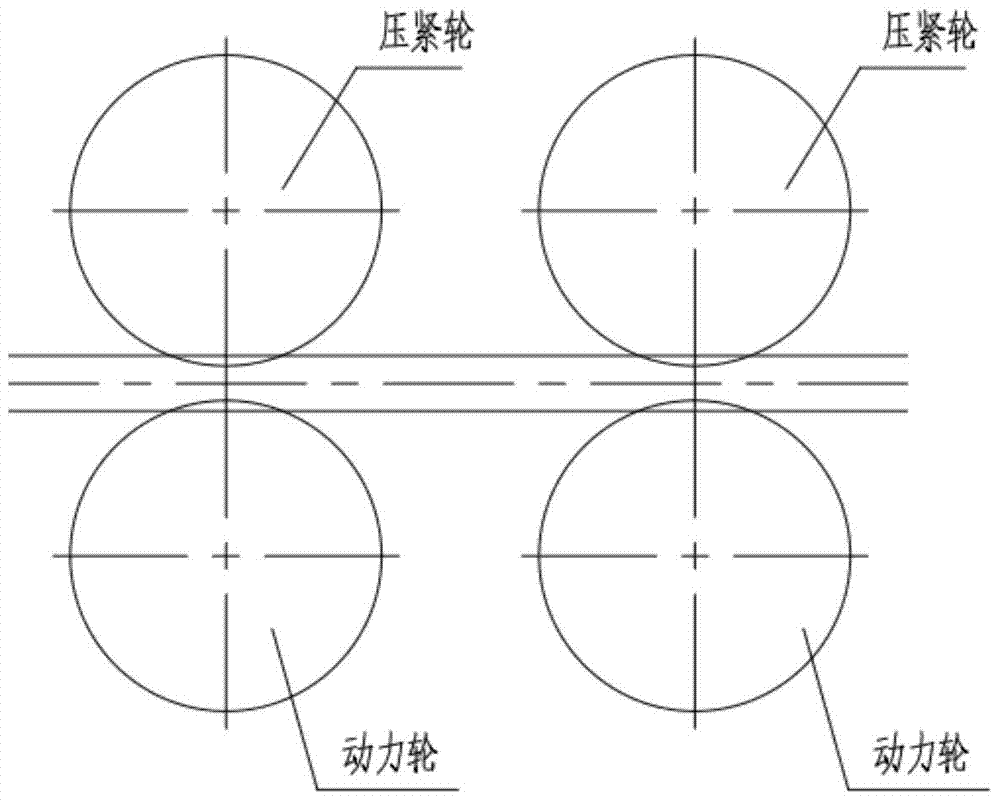

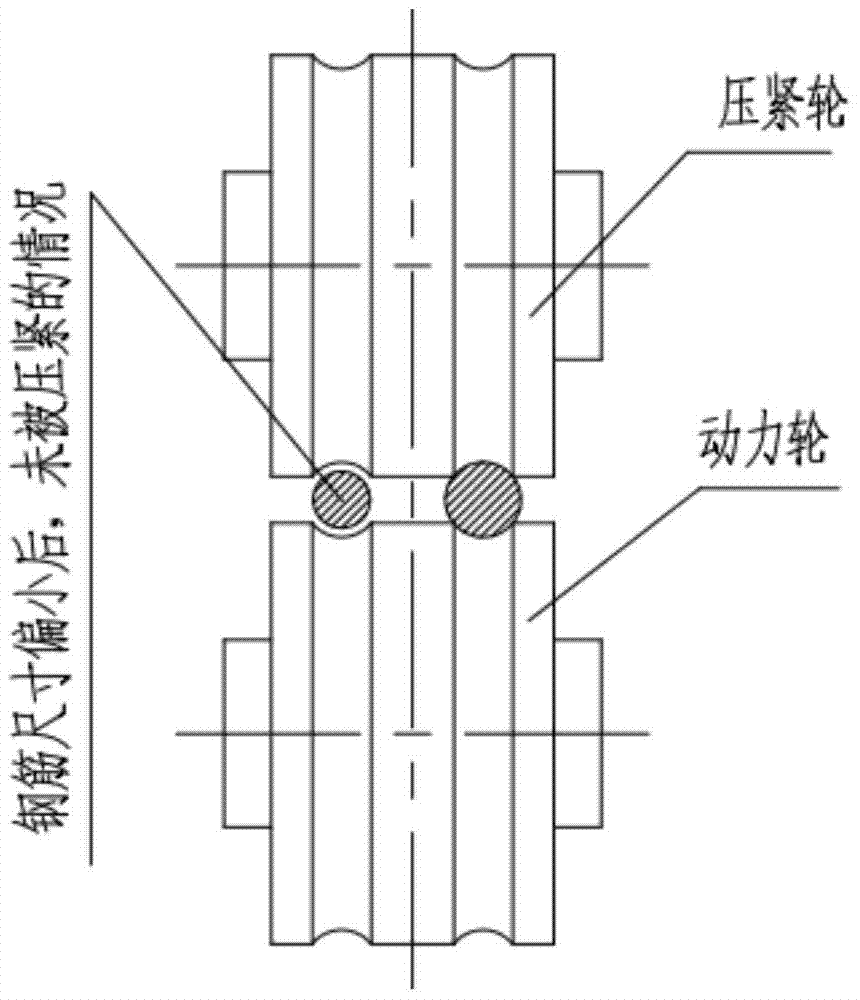

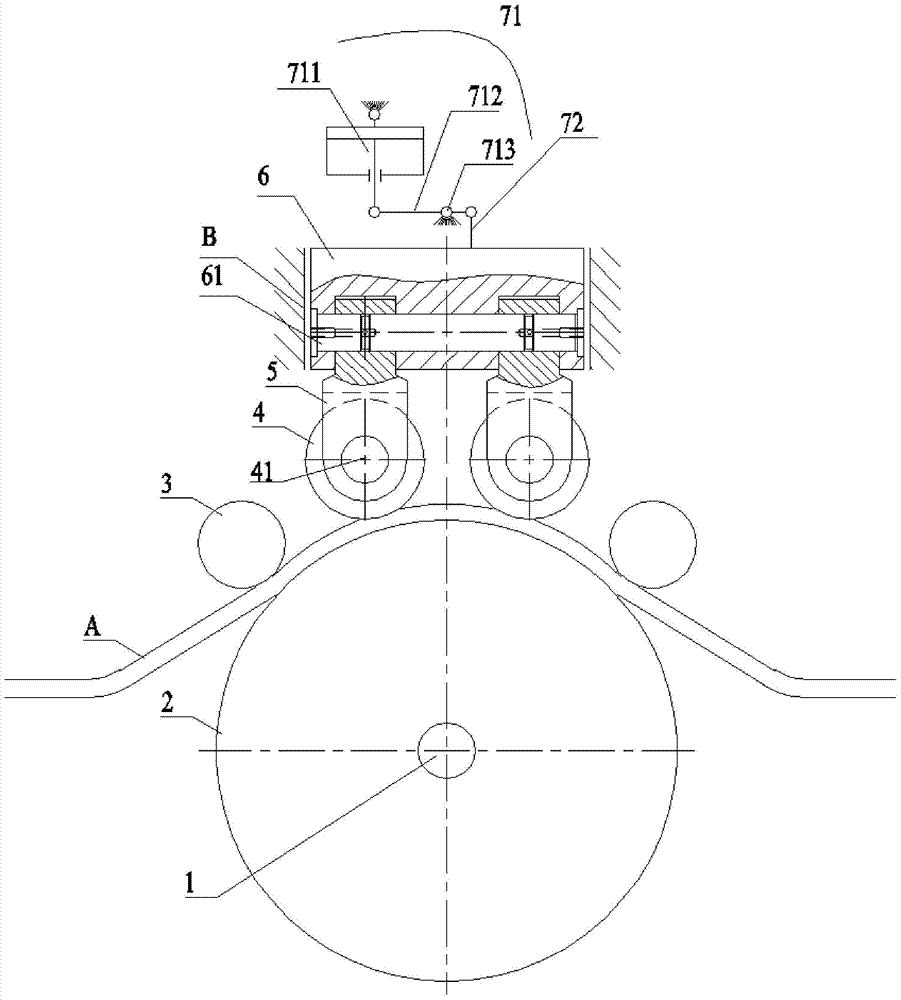

[0021] see image 3 and Figure 4 , the anti-skid device for the driving wheel of the double-line steel bar hoop bending machine of the present invention includes the driving wheel 2 driven by the driving main shaft 1, the straightening wheels 3 arranged on both sides of the driving wheel 2, and at least two wheels arranged on both sides of the center line of the driving wheel 2. A pinch wheel 4, this pinch wheel 4 is an integral type, can press down two reinforcing bars A simultaneously, and the integral pinch wheel 4 adopts flat wheel structure. The pinch wheel 4 is easy to wear and tear due to direct contact with the steel bar A, and should be made of high-strength wear-resistant material and surface hardened. Further, it also includes a pressing wheel seat 5 whose lower end is connected to the axis 41 of the pressing wheel 4, and the upper part of the pressing wheel seat 5 is arranged in the machine base, and its two sides are in clearance fit with the machine base B.

...

Embodiment 2

[0029] see Figure 5 and Figure 6 , the second embodiment is roughly the same as the anti-skid device for the driving wheel of the double wire hoop bending machine of the first embodiment, the only difference is that the main pressing device 71 is a hydraulic cylinder, and the output shaft of the piston of the hydraulic cylinder is movably connected to the connecting rod 62A. The output force of the hydraulic cylinder is relatively large, which can directly provide downforce for the pressing wheel 4A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com