Automatic pressing system for components of tire forming machine

A tire building machine and component technology, applied in the field of rubber products, can solve the problems of increased labor intensity of operators, low speed, inconsistent pressing force, etc., and achieve the effects of saving labor intensity, improving quality, and ensuring consistent pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

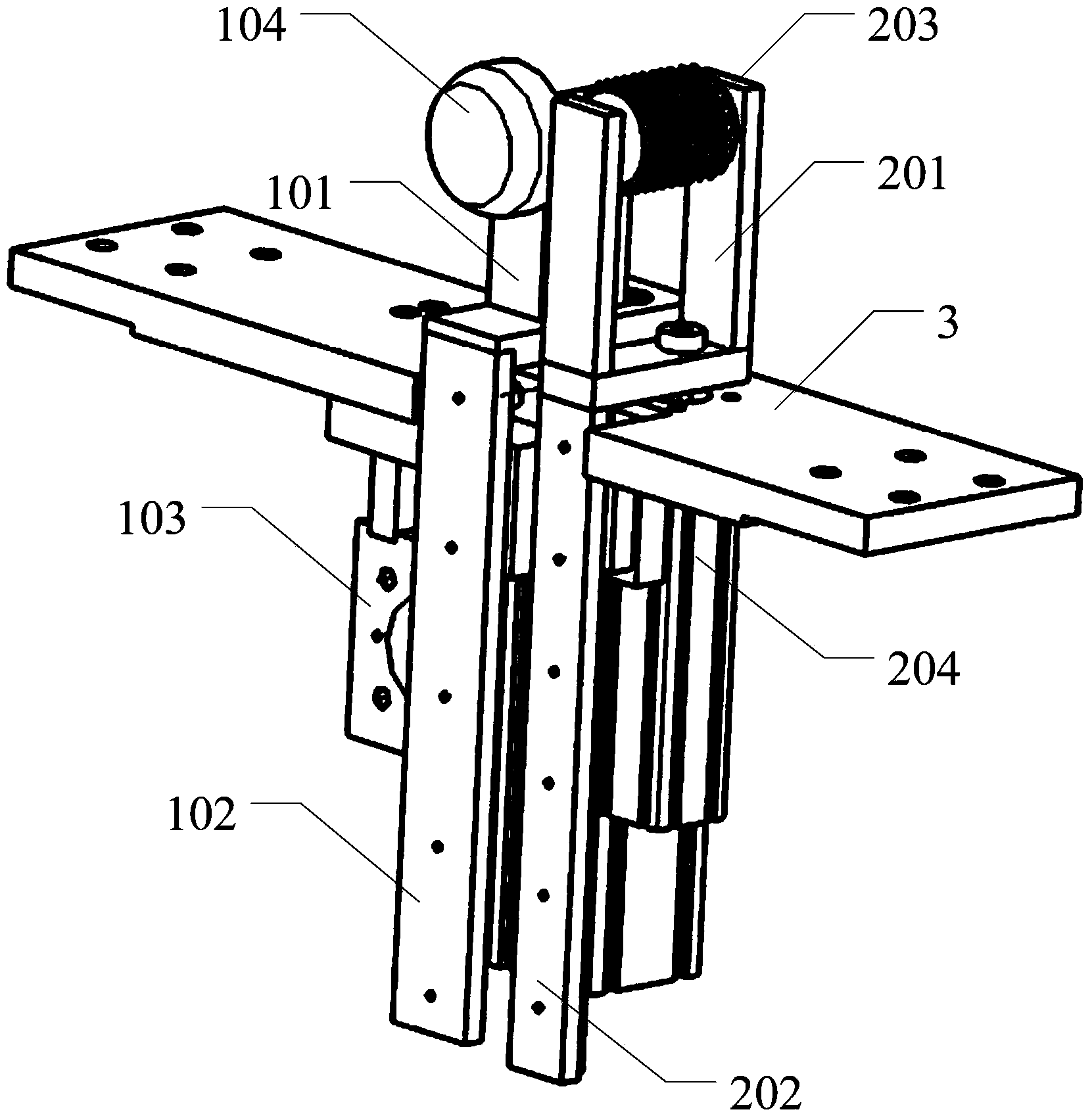

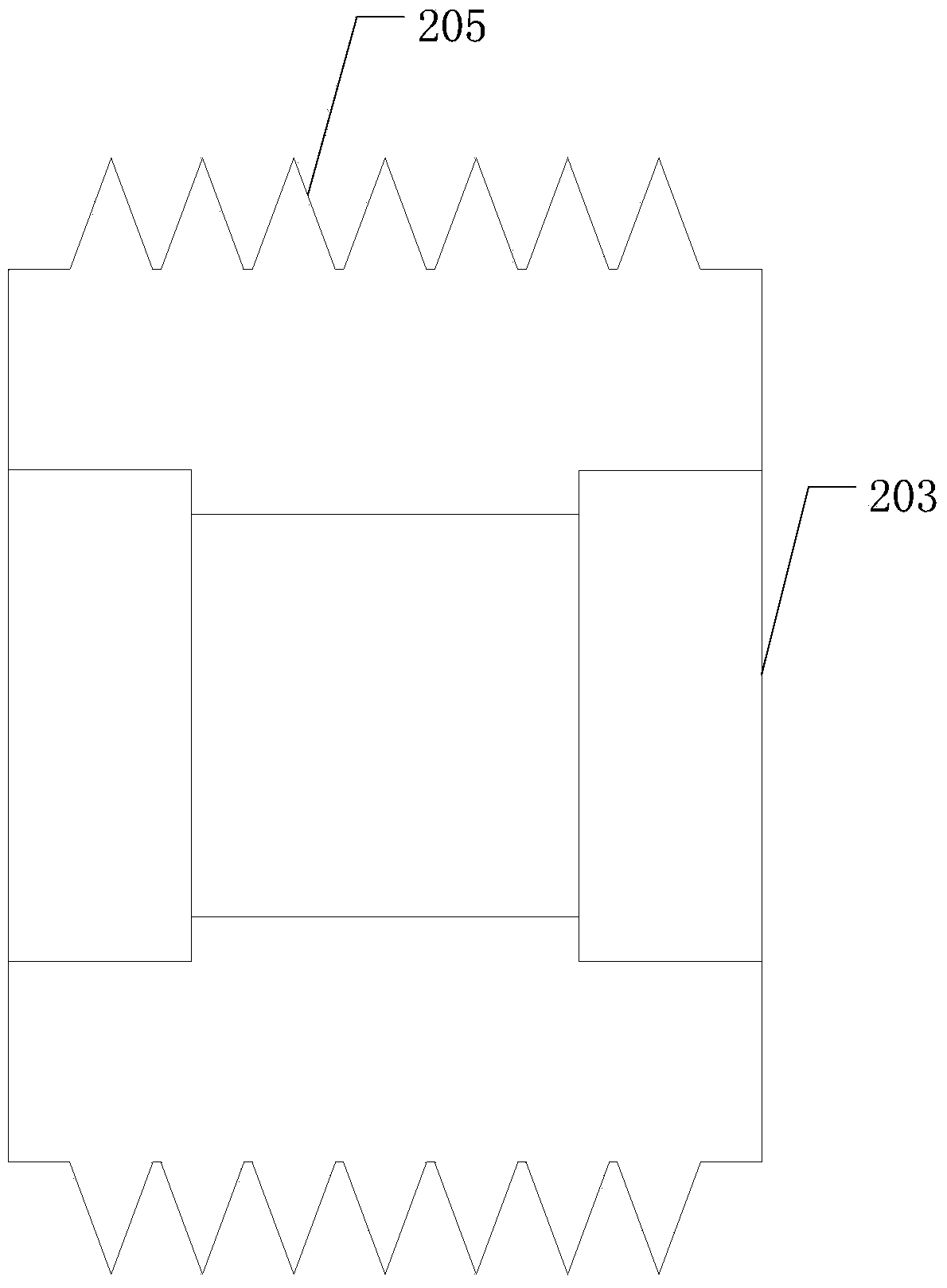

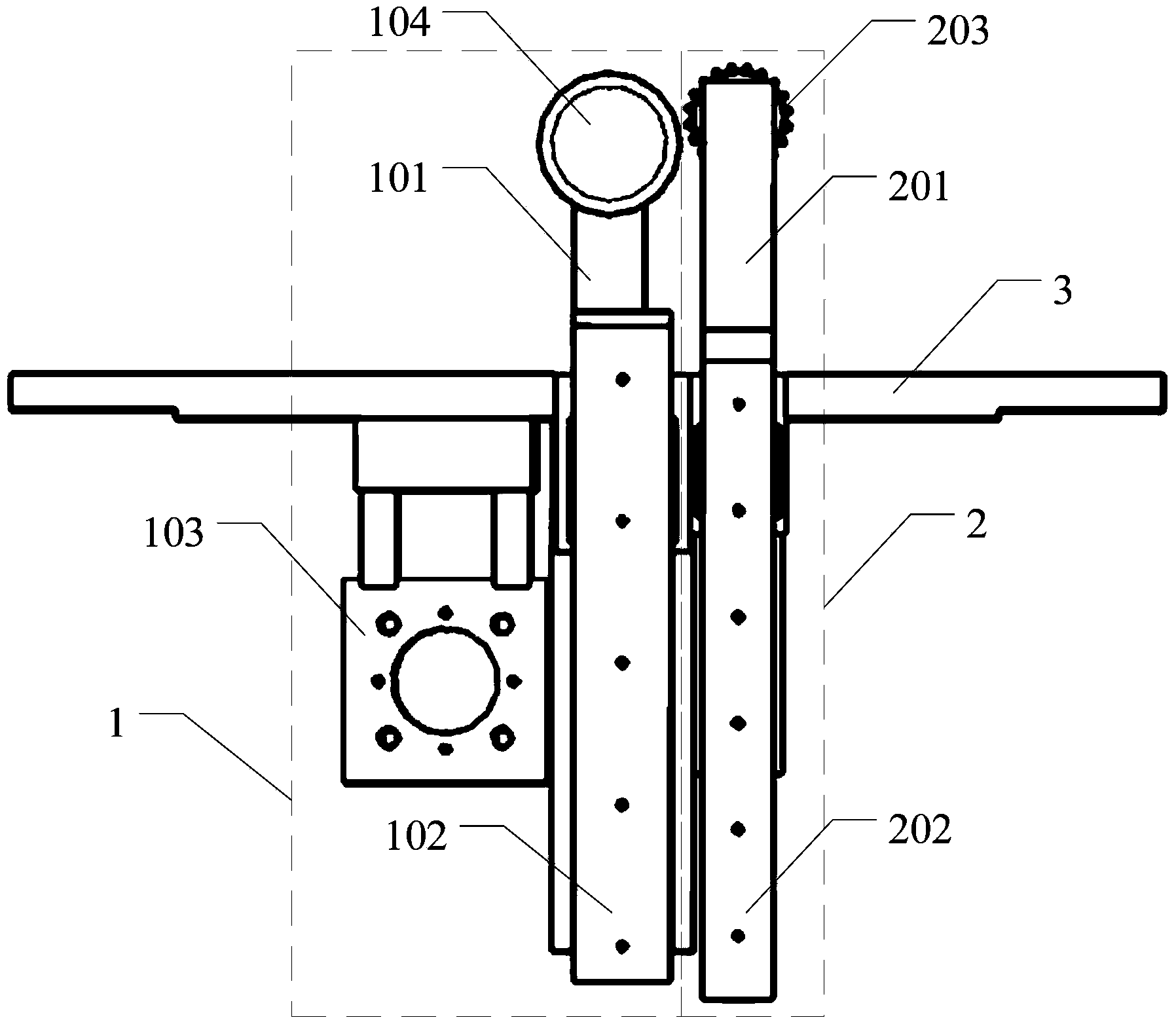

[0036] The embodiment of the present invention provides an automatic pressing system for parts of a tire building machine. The forming drum that has already been mounted on the side tire is put into the system, and first pressed through the burr roller device, and then passed through the smooth circumferential roller of the lower pressure roller device. The flat pressure squeezes out the air between the sidewall and the forming drum, making the two fit perfectly and avoiding isolation. At the same time, it saves the labor intensity of the operator, ensures consistent pressing force, and improves the quality of the tire.

[0037] The technical solutions in the embodiments of the present invention will be described clearly and in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. Based on the embodiments of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com