Casting and retreating device for press plate

A pressing plate and sleeve technology, applied to electrical components, substation/switch layout details, etc., can solve the problems of different operator force, loose protection pressing plate, easy to miss screwing nuts, etc., to achieve easy portability, electrical circuit The performance is not affected, and the effect of good upper and lower contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

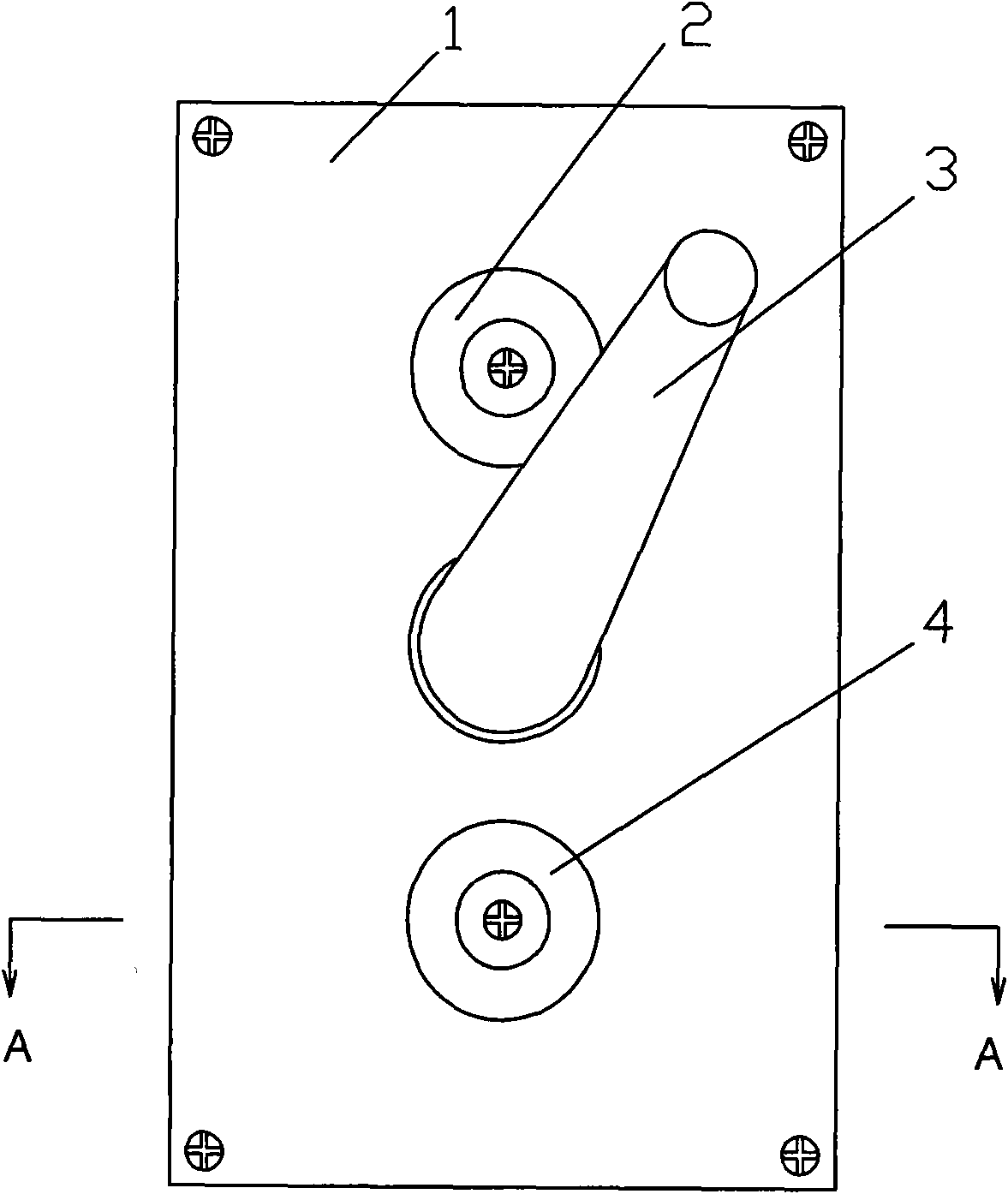

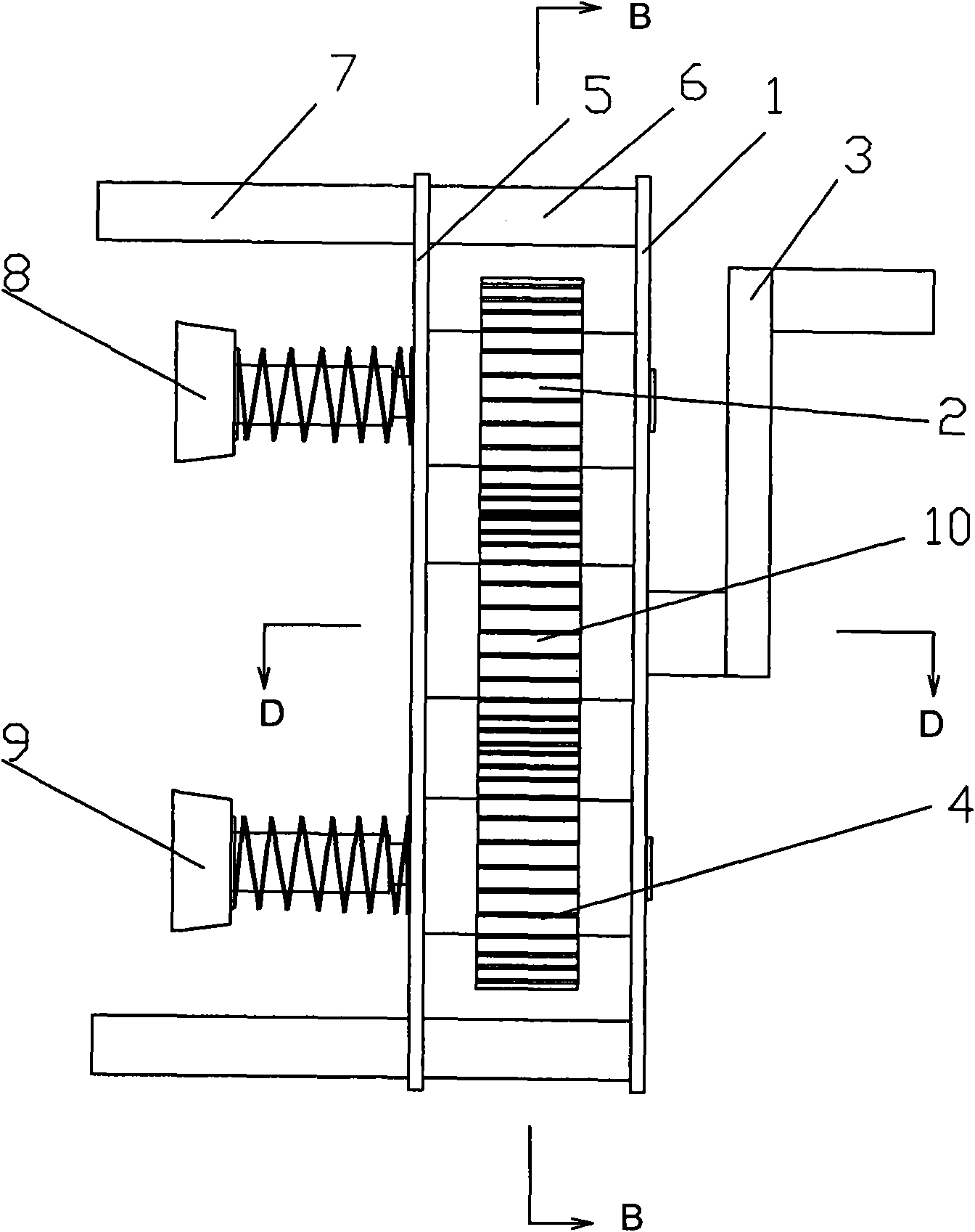

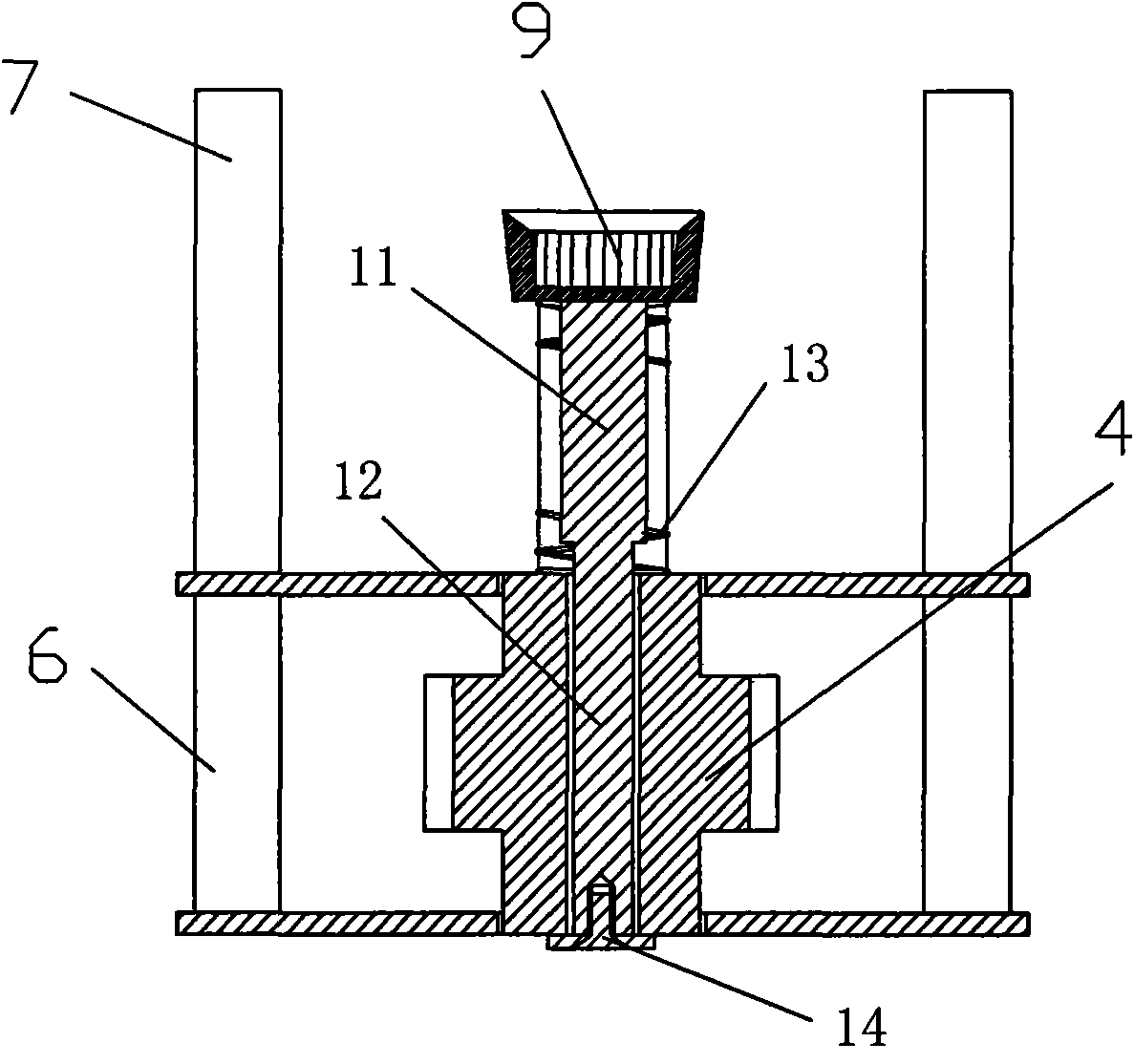

[0016] Example: as Figure 1-6 The shown pressure plate ejector includes a casing, the casing includes a front plate 1 and a rear plate 5, a fixed bracket 6 is arranged between the front plate 1 and the rear plate 5, and a transmission gear 10 is arranged between the front plate 1 and the rear plate 5 , upper gear 2 and lower gear 4, the upper and lower gears 2, 4 are meshed with the transmission gear 10 respectively, the outer end of the transmission gear 10 is provided with a rotating handle 3, and the inner ends of the upper and lower gears 2, 4 are respectively provided with There are upper and lower sleeves 8 and 9. The distance between the upper and lower sleeves 8 and 9 is equal to the distance between the upper and lower nuts of the pressing plate. The wedge-shaped hole is provided with protruding teeth extending along the depth direction of the hole on the inner peripheral wall of the hole.

[0017] The rear ends of the upper and lower sleeves 8 and 9 are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com