An adjustable pressure double-sided compression sealing device

A compression sealing, double-sided technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as increased use cost, inability to achieve compression deformation, seal failure, etc., to save costs and improve sealing effect. and use time, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

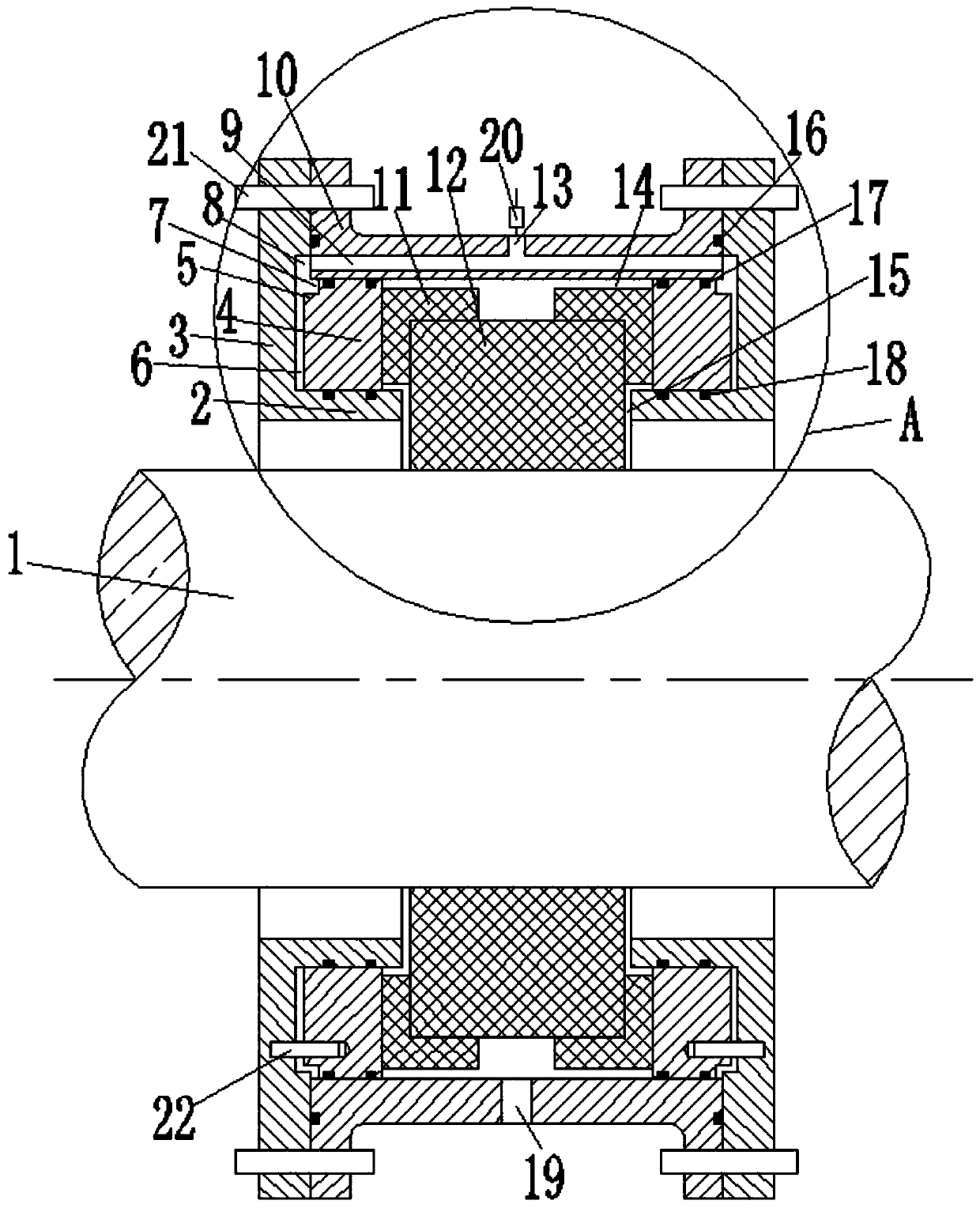

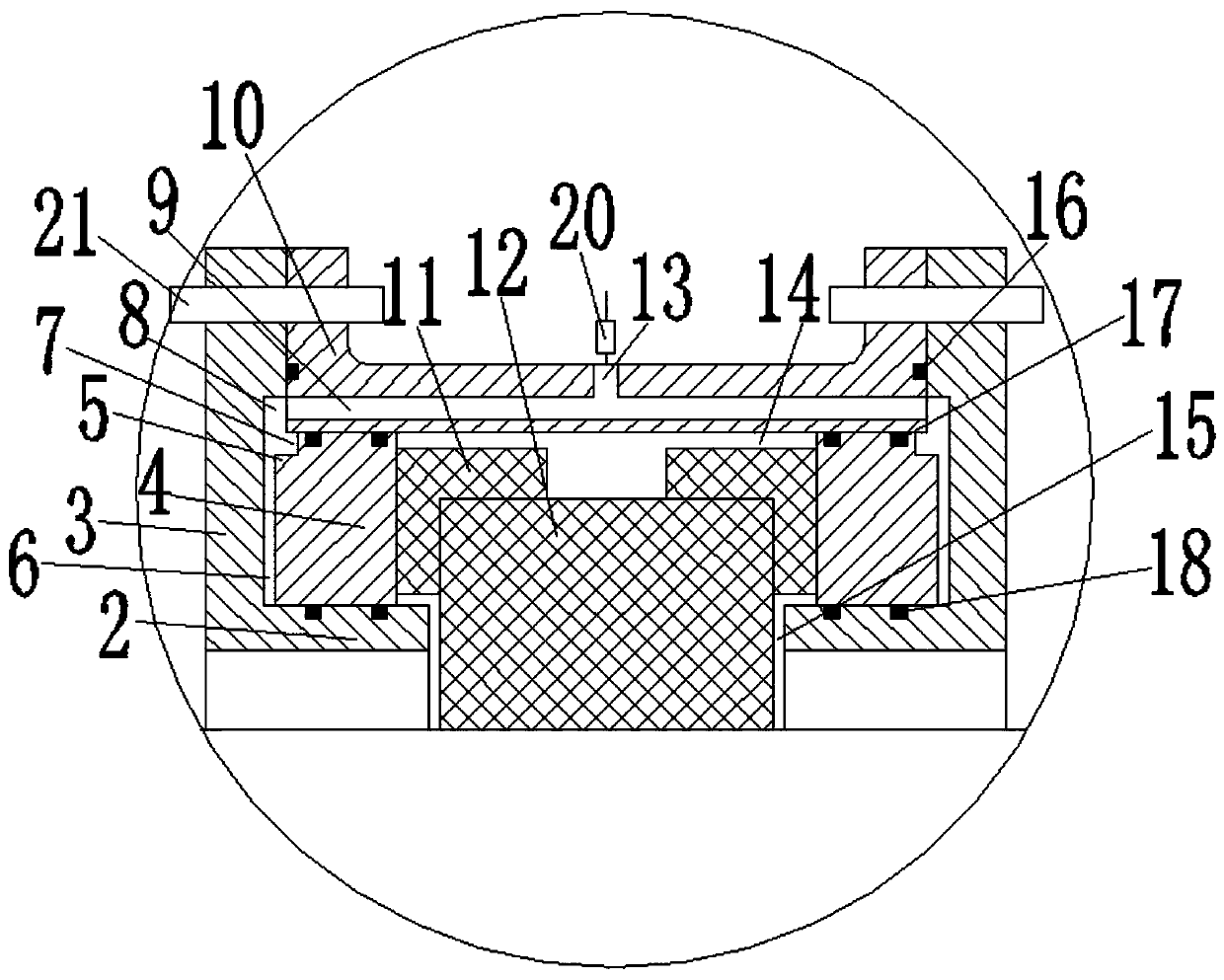

[0024] Such as figure 1 and image 3 As shown, an adjustable pressure double-sided compression sealing device includes a rotating shaft 1 and two sealing covers that are sleeved on the outer periphery of the rotating shaft 1 and are separated from each other. Each sealing cover includes an annular cover body 3 and is arranged inside the annular cover body 3 The flange ring 2 at the end of the flange ring 2 is provided with an elastic member 12 fixed on the outer periphery of the rotating shaft 1 between the two flange rings 2. There is a first gap 15 between the elastic member 12 and the flange ring 2, and the two sides of the elastic member 12 are respectively fixed. There is a dynamic sealing ring 11, a static sealing ring 4 is provided on the outer periphery of the flange ring 2, and a sealing seat 10 for pressing the static sealing ring 4 against the flange ring 2 is installed between the two annular covers 3, the sealing seat 10 It is fixed with the annular cover 3 and i...

Embodiment 2

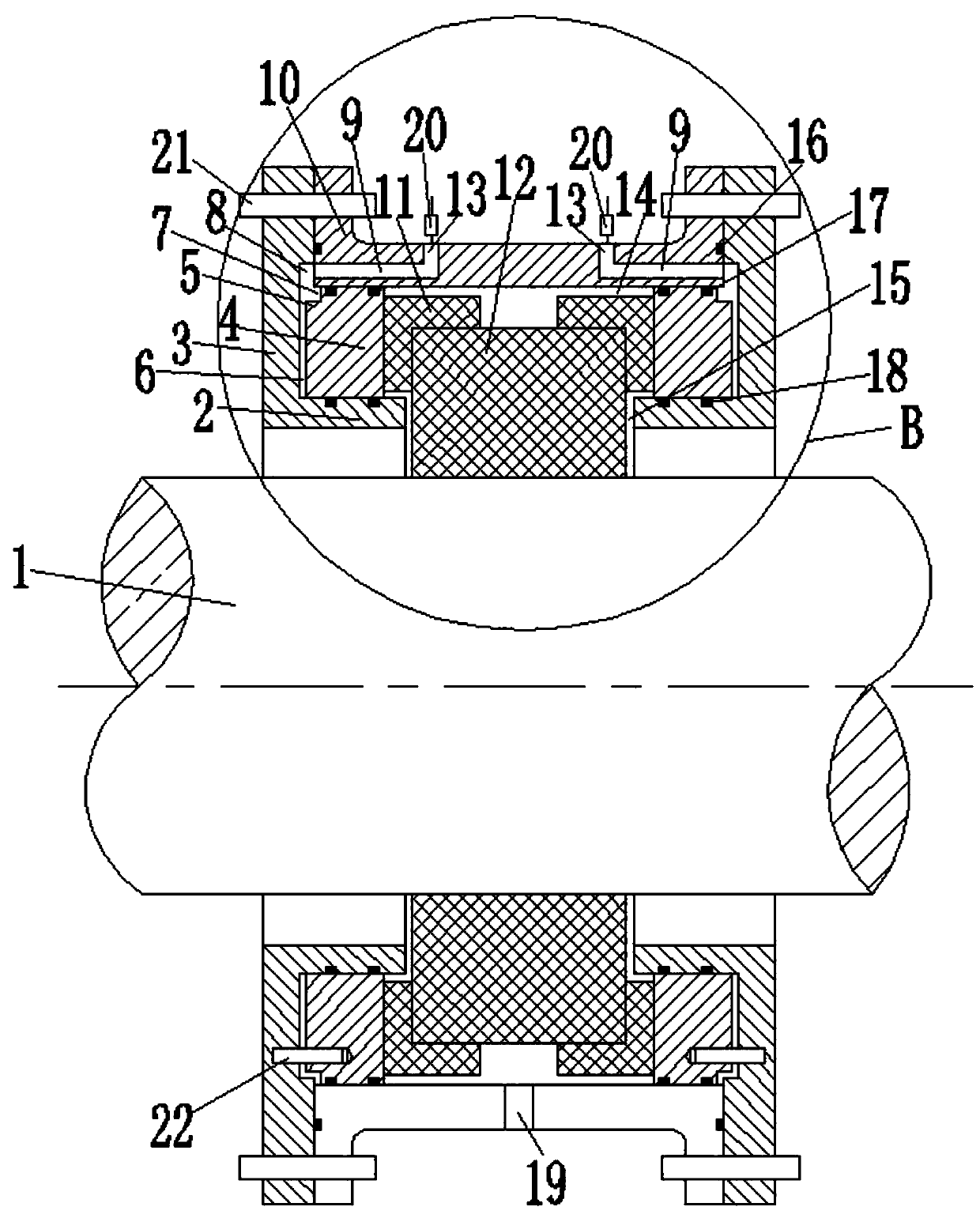

[0027] Such as figure 2 and Figure 4As shown, an adjustable pressure double-sided compression sealing device includes a rotating shaft 1 and two sealing covers that are sleeved on the outer periphery of the rotating shaft 1 and are separated from each other. Each sealing cover includes an annular cover body 3 and is arranged inside the annular cover body 3 The flange ring 2 at the end of the flange ring 2 is provided with an elastic member 12 fixed on the outer periphery of the rotating shaft 1 between the two flange rings 2. There is a first gap 15 between the elastic member 12 and the flange ring 2, and the two sides of the elastic member 12 are respectively fixed. There is a dynamic sealing ring 11, a static sealing ring 4 is provided on the outer periphery of the flange ring 2, and a sealing seat 10 for pressing the static sealing ring 4 against the flange ring 2 is installed between the two annular covers 3, the sealing seat 10 It is fixed with the annular cover 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com