A lens automatic pressing device for a projection unit

A technology of pressing device and lens, applied in assembly machines, transportation and packaging, metal processing equipment, etc., can solve the problems of high labor intensity, low production efficiency, lens shaking, etc., to avoid shaking and breaking, reduce labor intensity, Easy and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

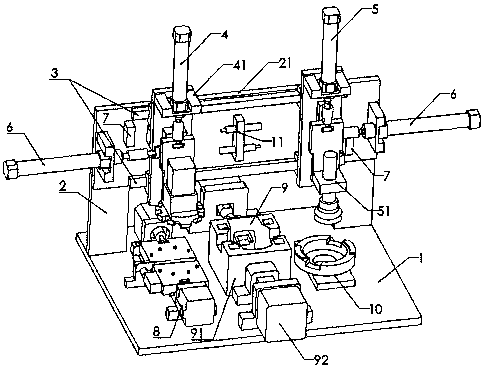

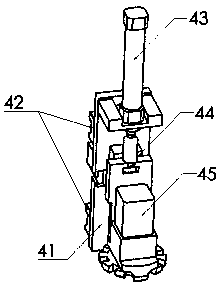

[0015] Depend on figure 1 Known, an automatic lens pressing device for a projection unit includes a workbench 1, a gantry 2 is arranged on the workbench 1, and a beam 21 on the gantry 2 spans above the workbench 1; There is a guide rail 3, and the two ends of the guide rail 3 are respectively movably connected with the clamping ring grabbing part 4 and the lens grabbing part 5. Laterally moving part 6; on the workbench 1, from left to right, there are fixedly installed a pressure ring positioning mechanism 8, a pressing mechanism 9 and a lens positioning mechanism 10; the installation position of the pressure ring positioning mechanism 8 corresponds to the pressure ring grasping part 4, The installation position of the lens positioning mechanism 10 corresponds to the lens grabbing part 5 . The crossbeam is respectively provided with limit blocks 7 between the lateral moving part 6 and the clamping ring grabbing part 4 and between the lateral moving part 6 and the lens grabbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com