M1 line door seal automatic pressing machine

A pressing machine and seal technology, which is applied in the field of M1 line door seal automatic pressing machine, can solve the problems of inconsistent pressing quality, inability to adjust, and difficult control of pressing force, so as to improve the degree of automation, increase the scope of application, and reduce labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

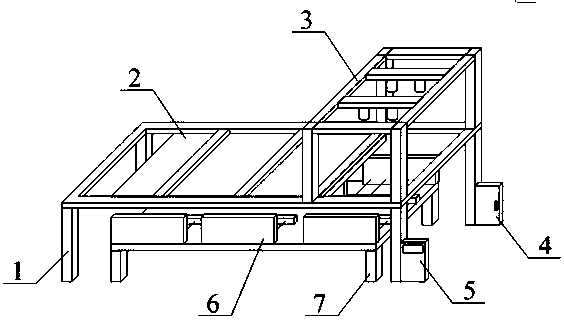

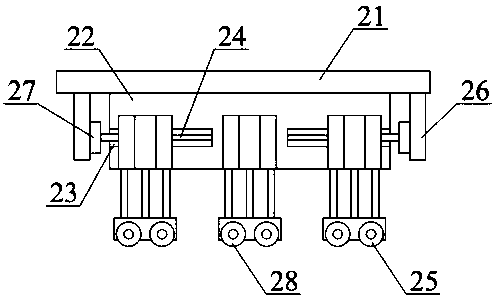

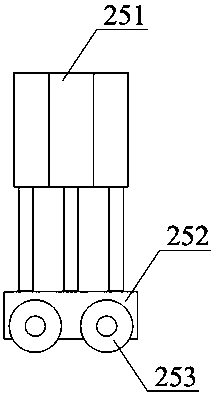

[0025] as attached figure 1 to attach Image 6 shown

[0026] The invention provides an automatic pressing machine for M1 line door seals, which includes a mounting bracket 1, a pressing assembly 2, a visual sensing assembly 3, an electric control cabinet 4, a PLC controller 5, a centering assembly 6 and a support plate 7. The pressing component 2 is fixed above the inside of the mounting bracket 1 by bolts; the support plate 7 is arranged below the mounting bracket 1; the visual sensing component 3 is fixed on one end above the mounting bracket 1 by bolts; the centering component 6 adopts three, and the centering assembly 6 is fixed on the top of the support plate 7 by bolts, and the centering assembly 6 is aligned with the pressing assembly 2 and the visual sensing assembly 3; the electric control cabinet 4 is fixed on the installation bracket 1 by bolts Close to the rear side below the side of the visual sensing component 3, and the electric control cabinet 4 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com