A kind of holding mechanism used on the pcb board furnace carrier

A technology of PCB board and pressure holding mechanism, which is applied in the orientation of circuit board tools, assembling printed circuits with electrical components, printed circuits, etc. High and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

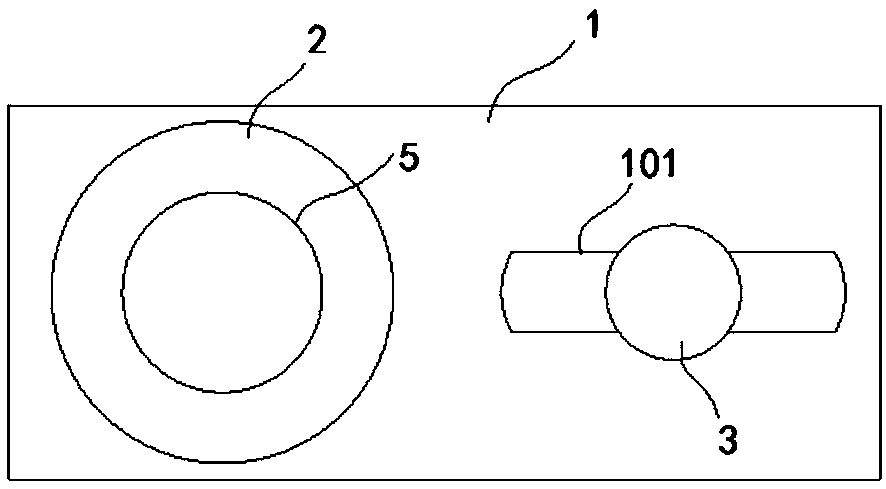

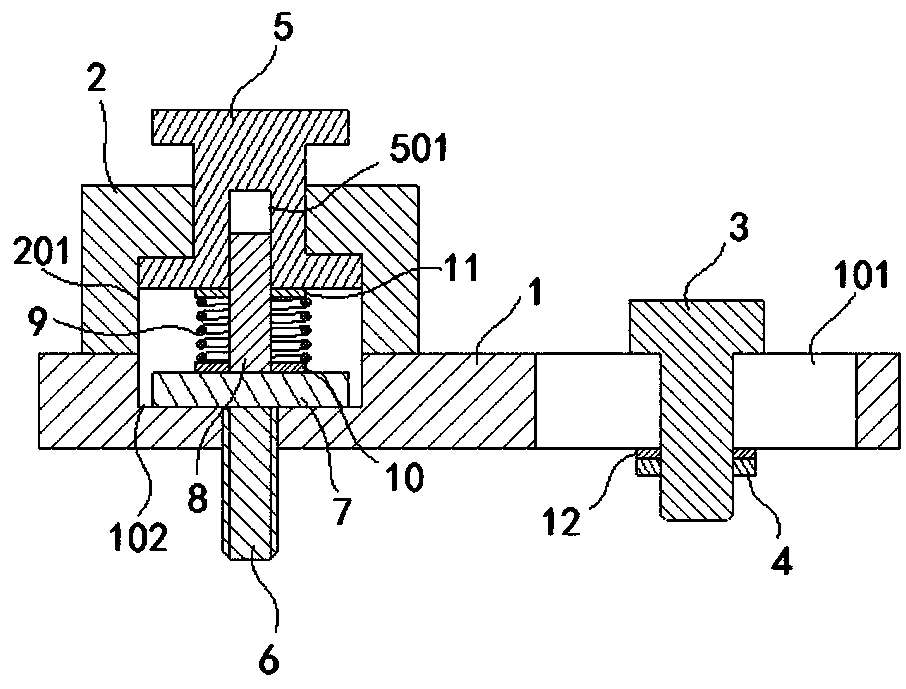

[0024] Such as figure 1 , figure 2 As shown, a kind of pressing mechanism used on the PCB board furnace carrier of the present invention includes:

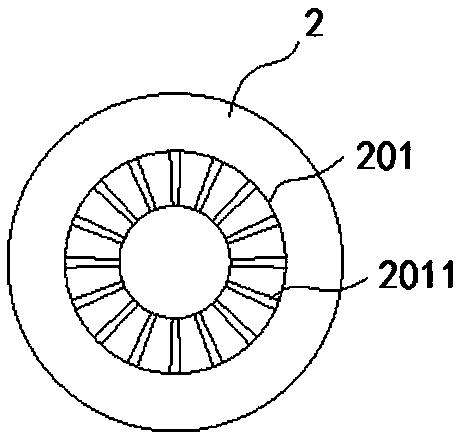

[0025] Pressing plate 1, the first end of the pressing plate 1 is formed with a positioning groove 101, the second end of the pressing plate 1 is formed with a bump 2, and the lower end of the pressing plate 1 is formed with a first stepped hole 102, such as image 3 As shown, the protruding block 2 is formed with a second stepped hole 201 , and a locking groove 2011 is formed on the lower end surface of the second stepped hole 201 , and the first stepped hole 102 communicates with the second stepped hole 201 . The upper end of the first stepped hole 102 is a large hole, the lower end of the first stepped hole 102 is a small hole, the upper end of the second stepped hole 201 is a small hole, and the lower end of the second stepped hole 201 is a large hole. The large hole of the first stepped hole 102 communicates with the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com