Electrode plate roller type positioning press-fitting device

A technology of press-fitting device and electrode sheet, which is applied in the direction of electrode manufacturing, press machine, cleaning by electrostatic method, etc. It can solve the problems of affecting the use of roller pressure, dusty impurities, high cost of use, etc., and achieve stable transmission, good adsorption effect, Guarantee the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

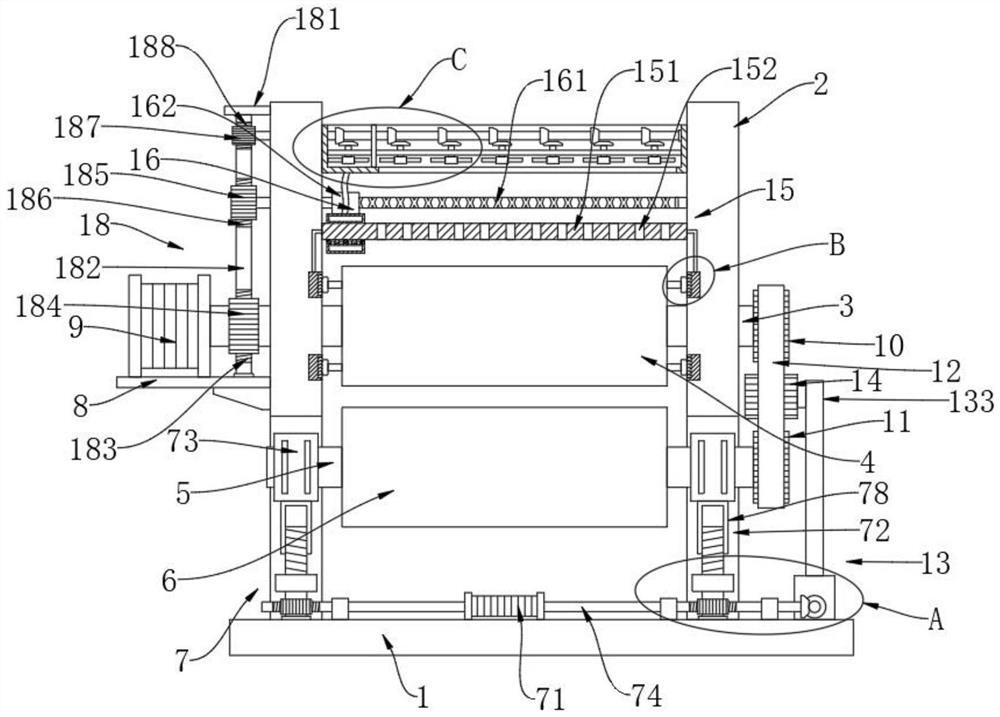

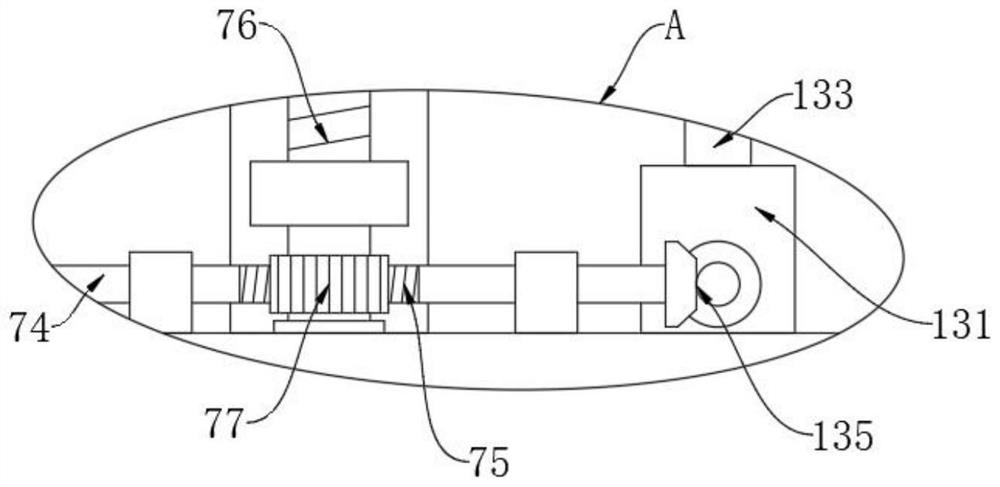

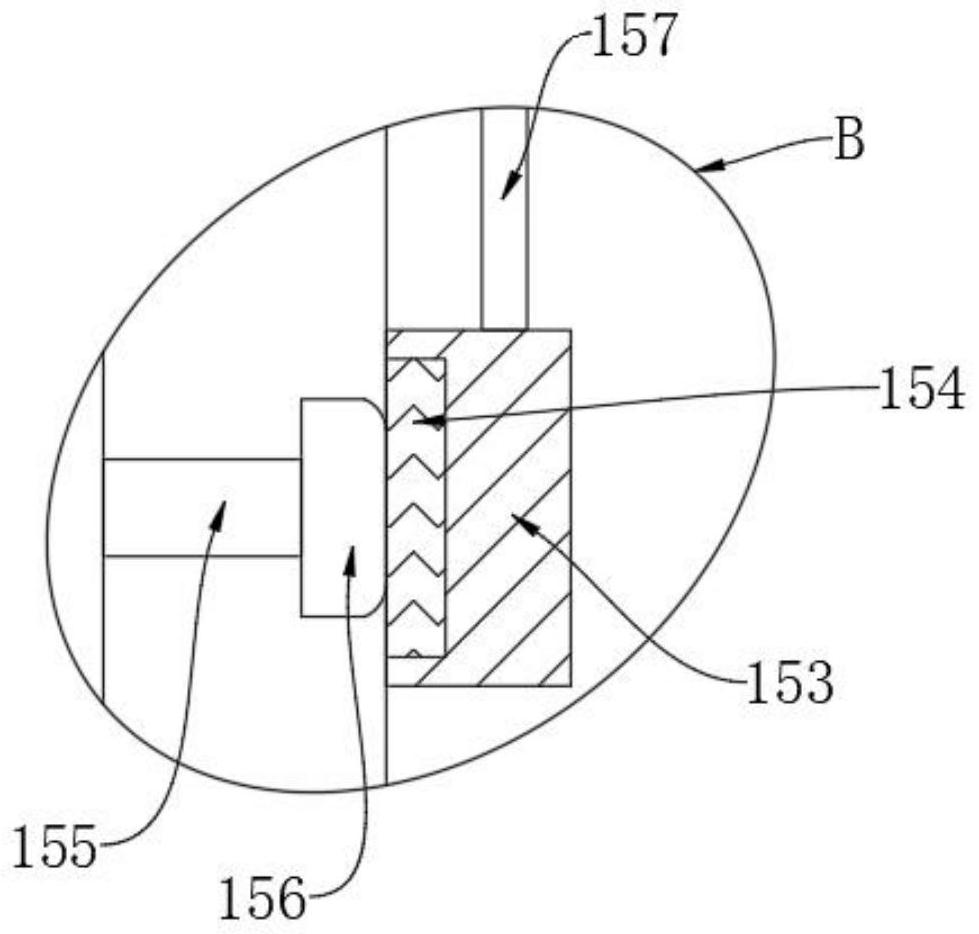

[0028] see Figure 1-6, an electrode sheet roller type positioning and pressing device, comprising a base 1, the upper end of the base 1 is symmetrically and fixedly connected with two side plates 2, and the opposite sides of the two side plates 2 are connected with an upper pressing roller through a first rotating shaft 3. 4. The opposite sides of the two side plates 2 are rotatably connected to the lower pressure roller 6 located on the lower side of the upper pressure roller 4 through the second rotating shaft 5, and the upper end of the base 1 is also fixedly connected with a lift adjustment for driving the lower pressure roller 6 to move up and down. The mechanism 7 is located on the outer side of the left side plate 2 and is fixedly connected with a support plate 8, the upper end of the support plate 8 is fixedly connected with a rotary motor 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com