Positive type adjustable tension yarn feeding device and work method thereof

A tension and positive technology, applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve problems affecting fabric properties, fluctuations in yarn tension, uneven fabric structure, etc., to avoid uneven effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

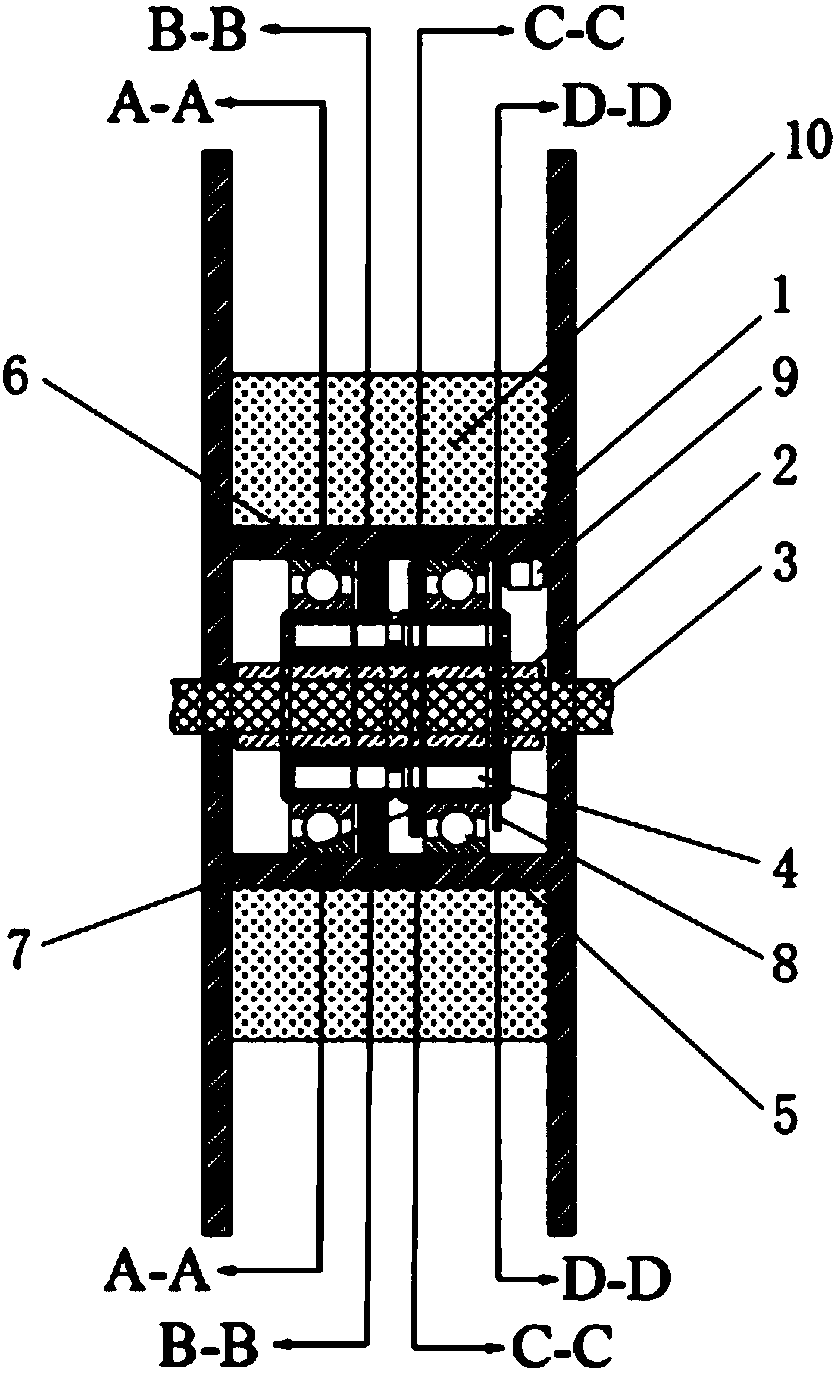

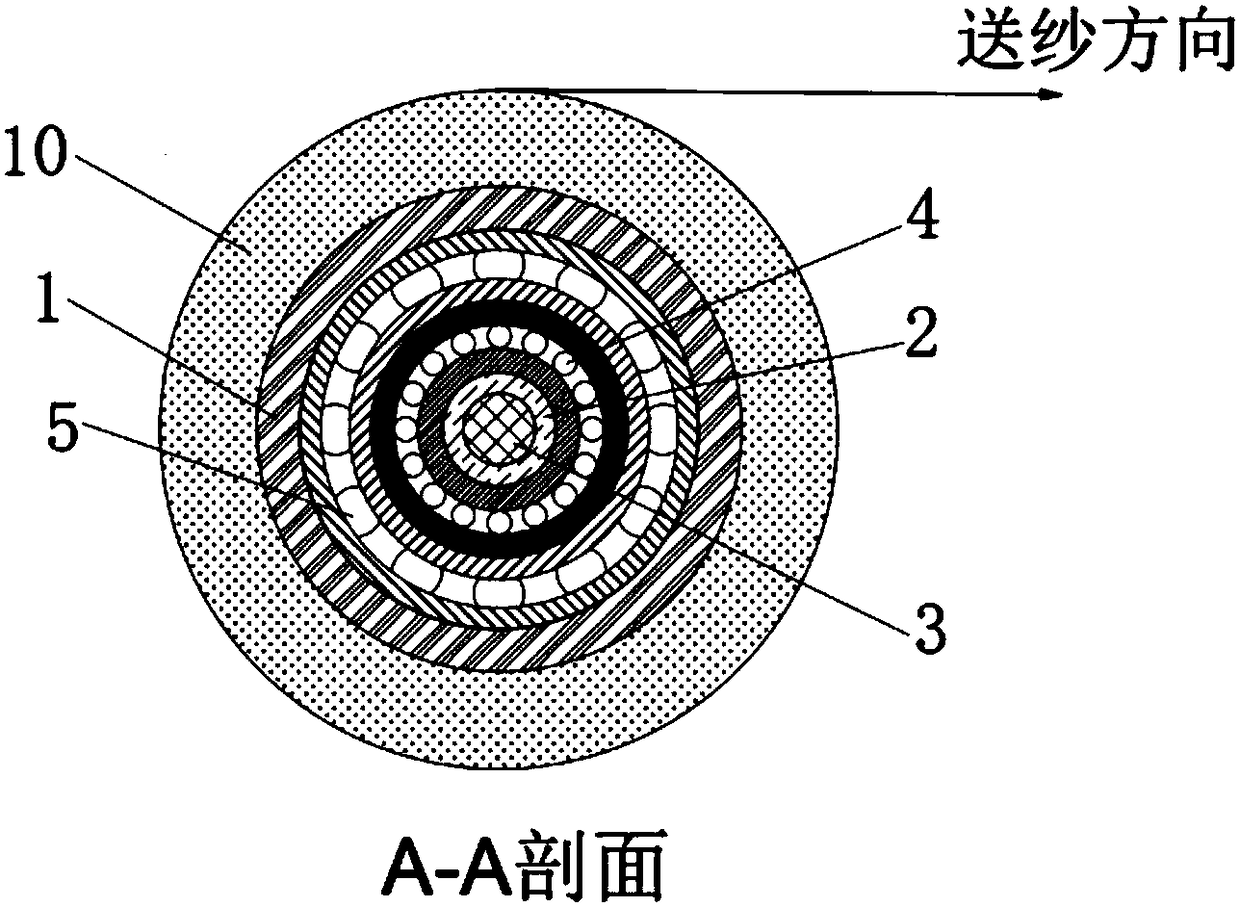

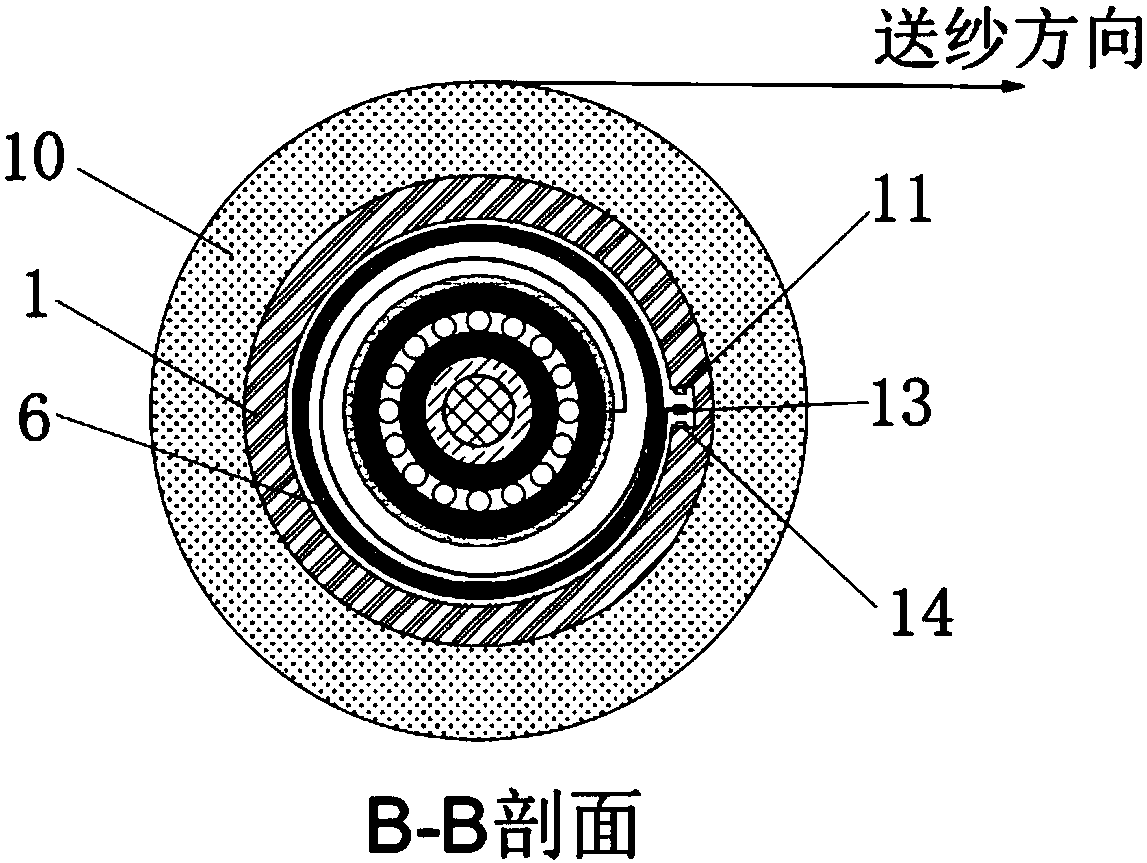

[0031] see figure 1 , a positive adjustable tension yarn feeding device of the present invention, which includes a yarn disc 1, a bearing mechanism, a clockwork spring mechanism, a DC motor gear pair mechanism, and a ratchet mechanism;

[0032] see figure 1 with figure 2 , the bearing mechanism includes two ball bearings 5 and a roller bearing 4, the two ball bearings 5 are installed on the inner side of the yarn disc 1, and the outer rings of the two ball bearings 5 and the inner side of the yarn disc 1 adopt a transition fit; the roller bearing 4 Installed in the inner rings of two ball bearings 5, the outer ring of the roller bearing 4 and the inner ring of the ball bearing 5 adopt a transition fit; a sleeve 2 is installed in the inner ring of the roller bearing 4, and the inner ring of the roller bearing 4 The ring and the outer wall of the sleeve 2 adopt a transition fit; the sleeve 2 is pierced with an optical axis 3, and the sleeve 2 and the optical axis 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com