A kind of cold rolling production method of ultra-thin stainless steel strip

A production method and technology of stainless steel strips, applied in rolling, metal rolling, metal rolling, etc., can solve problems such as low production efficiency, low rolling speed, and small reduction in passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A cold-rolling production method for an ultra-thin stainless steel strip, comprising the following steps:

[0028] The first step: blank preparation: select SUS430 raw material, BA blank of stainless steel strip with a thickness of 1.0mm and a width of 615mm.

[0029] The second step: the first rolling process: the billet is transported by the crane and the steel coil trolley to the uncoiler of the rolling mill, and enters the rolling mill after uncoiling. After the lead is wound to the coiler sleeve for two turns, the tension is established at 120KN, and 32% is given. Reduce the amount of reduction, then increase the speed of the uncoiler, rolling mill, and coiler to 100 m / min for steady-speed rolling. When the billet is almost rolled, perform slow-down rolling until parking, reverse after parking, and then reverse rolling , the reverse rolling speed is 120 m / min, so repeated reversible rolling, cold rolling 8 times, forming a semi-finished product with a thickness of ...

Embodiment 2

[0036] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0037] Select SUS304 raw material, 0.5mm thick, 610mm wide stainless steel strip 2B blank.

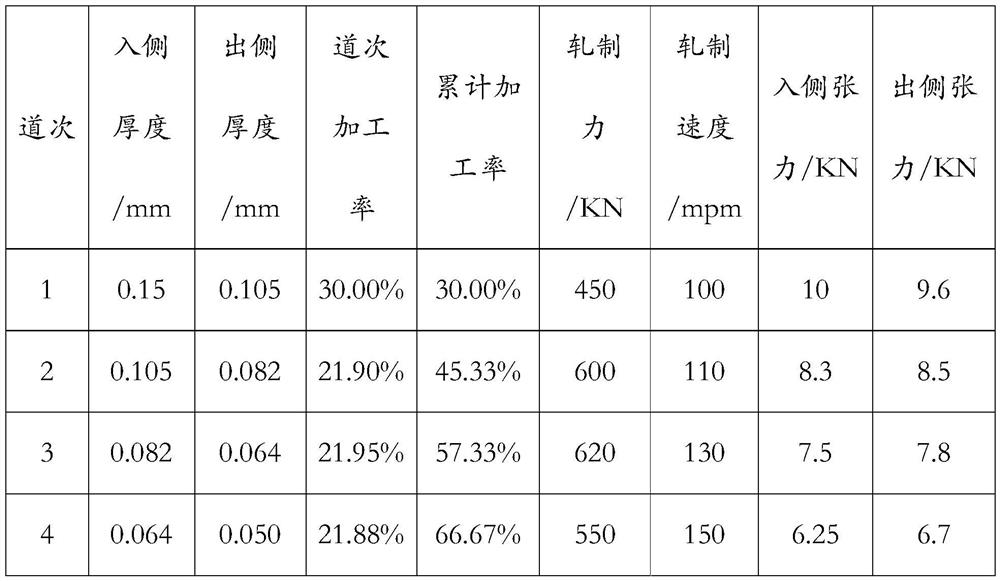

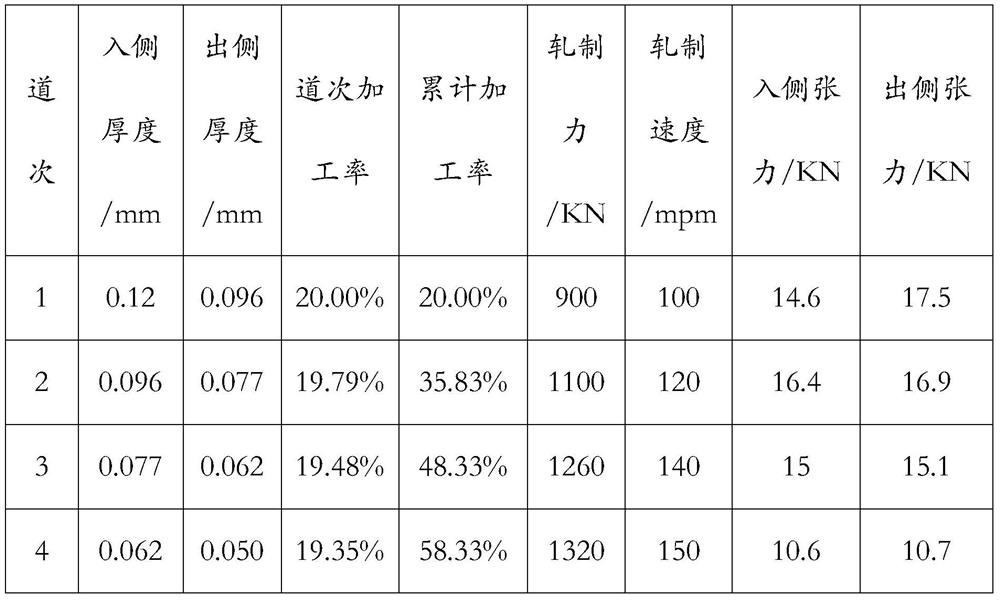

[0038] The first rolling process: establish a tension of 55KN and give a reduction of 30%. The uncoiler, rolling mill, and coiler are raised to 120 m / min for steady rolling. Reverse after parking, and then carry out reverse rolling, the reverse rolling speed is 140-180 m / min, so repeated reversible rolling, cold rolling 7 times, forming a semi-finished product with a thickness of 0.12mm.

[0039] Degreasing cleaning: The semi-finished product is transported by the crane to the uncoiler of the degreasing cleaning unit. After uncoiling, the head of the strip steel is welded by a lap welding machine, and then degreased, cleaned and dried by the S roller.

[0040] Continuous annealing: The semi-finished product enters the annealing furnace at a speed of 25 m / min. The temperature in t...

Embodiment 3

[0045] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0046] Select SUS301 raw material, 2B blank of stainless steel strip with a thickness of 1.5mm and a width of 610mm.

[0047] The first rolling process: establish a tension of 190KN, and give a reduction of 26%, the uncoiler, rolling mill, and coiler are raised to 80 m / min for steady rolling, and the reverse rolling speed is 100 m / min, so Repeated reversible rolling and cold rolling for 7 passes to form a stainless steel strip with a thickness of 0.5mm.

[0048] Degreasing and cleaning: The stainless steel strip with a thickness of 0.5mm is transported by a crane to the uncoiler of the degreasing and cleaning unit. area storage.

[0049] Continuous annealing: The stainless steel strip with a thickness of 0.5mm enters the annealing furnace at a speed of 9 m / min. The temperature in the annealing furnace is: 1100°C in the first zone, 1120°C in the second zone, 1140°C in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com