A Tension Control System of Fishing Vessel Trawl Winch

A trawl winch and tension control technology, applied in the field of fishing equipment, can solve problems such as tension changes, improve performance and life, and improve fishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

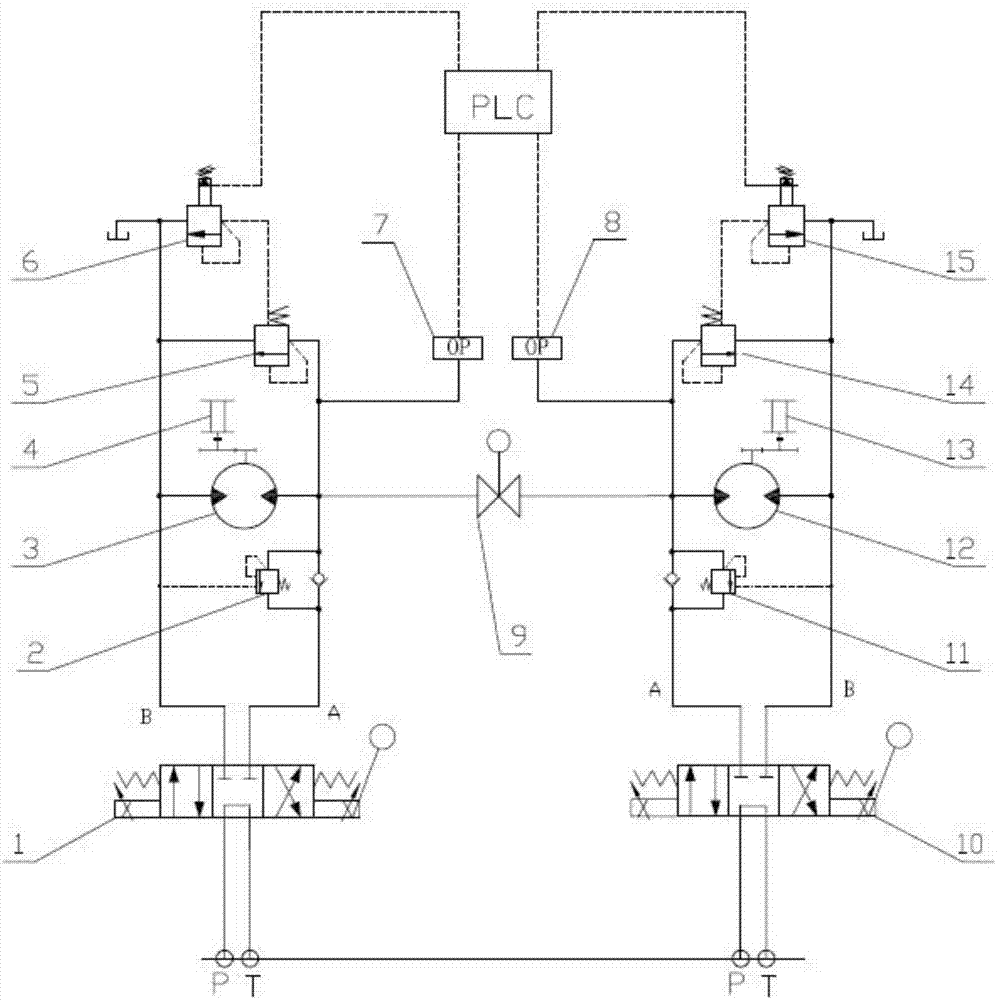

[0029] Such as figure 1 As shown, when lifting the net, the high-pressure oil enters the hydraulic motor (3, 12) through the proportional reversing valve to drive the hydraulic winch to rotate forward and lift the net. When the external load increases, the pressure of the hydraulic system increases, and the pulling force of the wire mesh machine increases. When the proportional directional control valve is in the left or right position, it can stabilize the pressure difference between the inlet and outlet ports of the proportional directional control valve by changing its own flow rate, avoiding the influence of load changes on the flow control, thereby realizing proportional flow control. In the neutral position, the valve is in the zero position when it is not in action, so the pressure oil flows out from the neutral oil return port of the manual reversing valve, and returns to the oil tank through the oil return pipe. At this time, the system is in an unloaded state, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com