Constant tension device of rotor spinning machine

A rotor spinning machine, constant tension technology, applied in the direction of spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the problem of periodically changing pulling force without effective control, yarn There are no compensation measures, reducing the working efficiency of the machine, etc., and achieve the effect of solving the problem of yarn tension fluctuation, simple and reliable structure, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

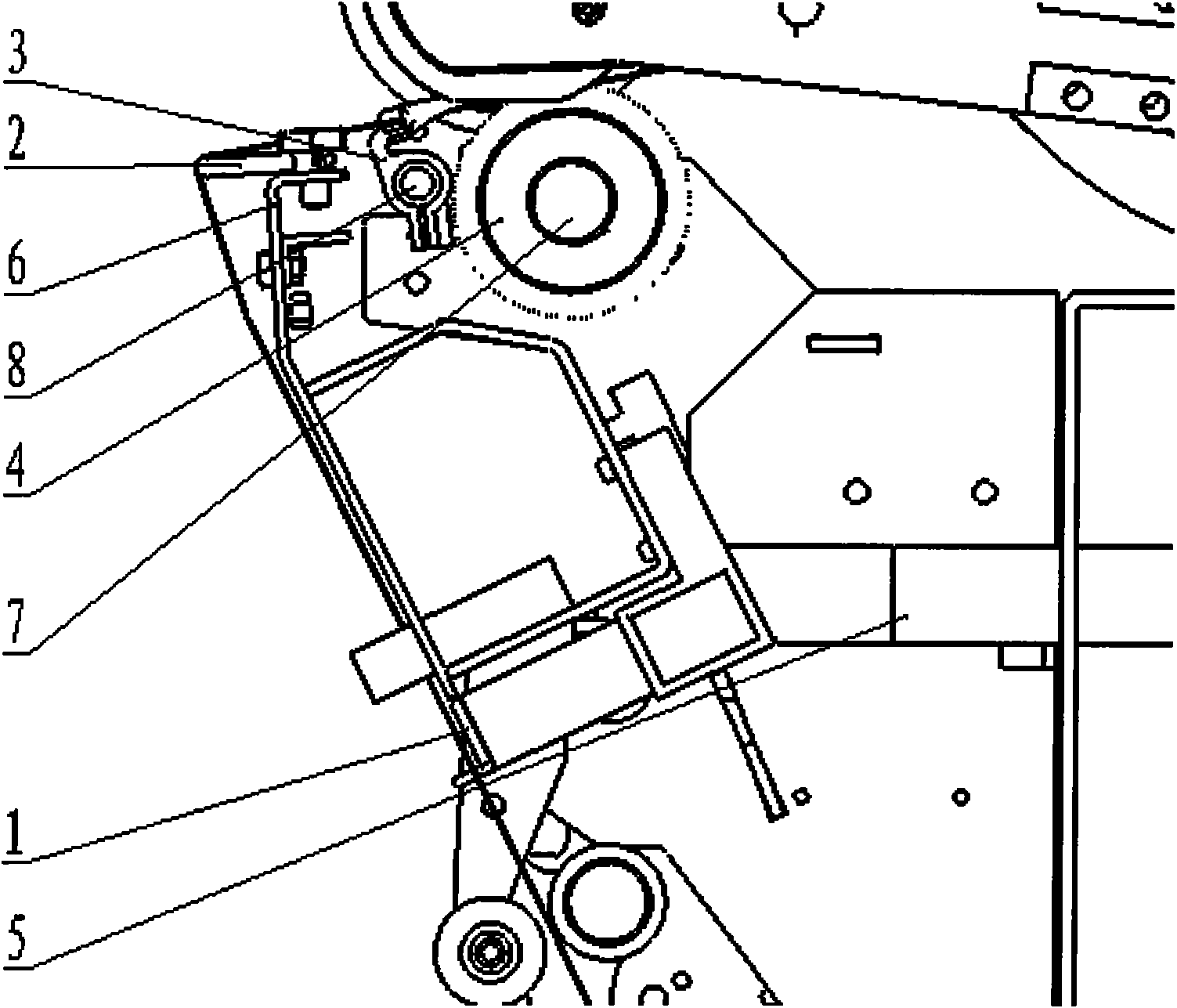

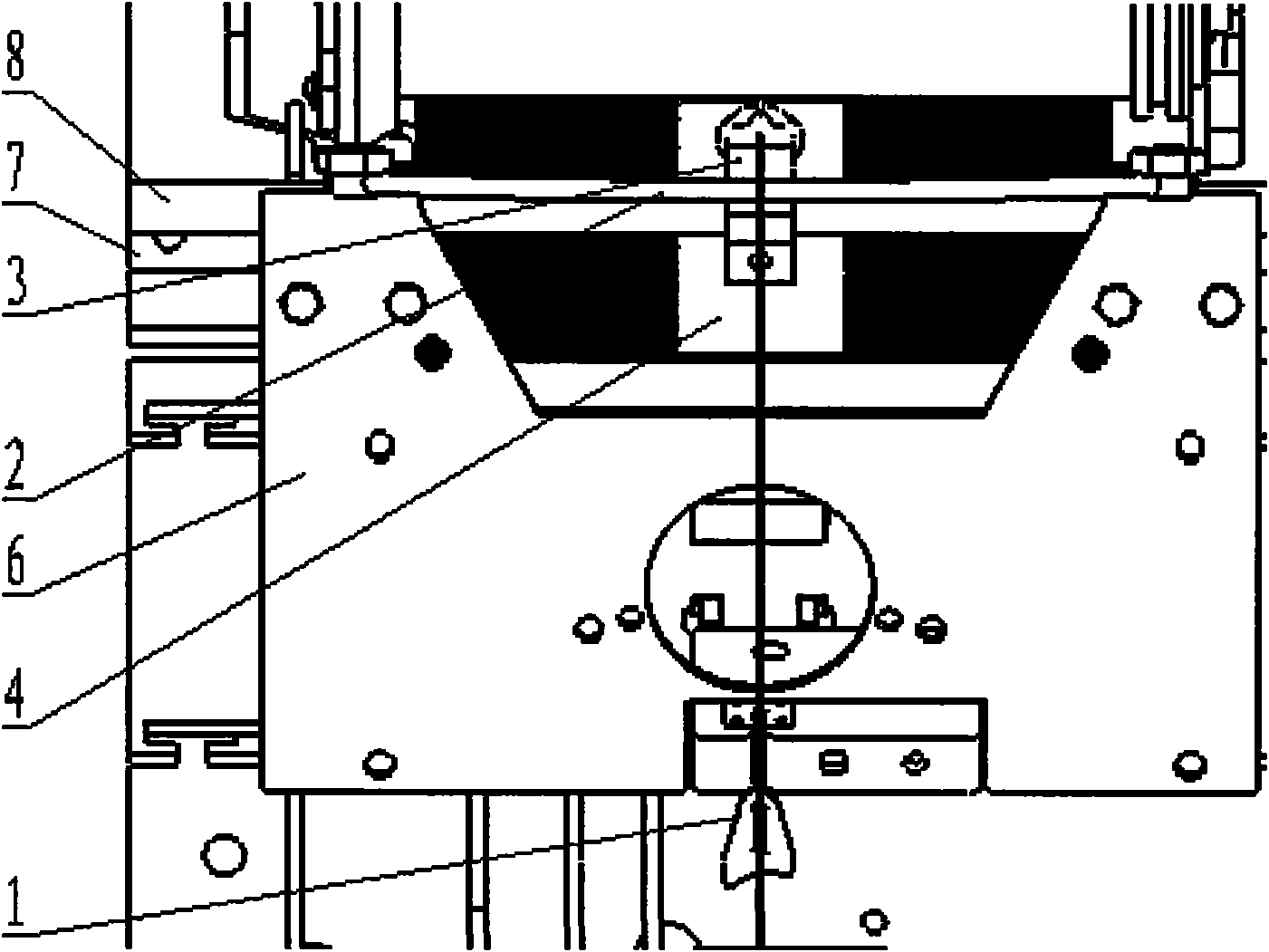

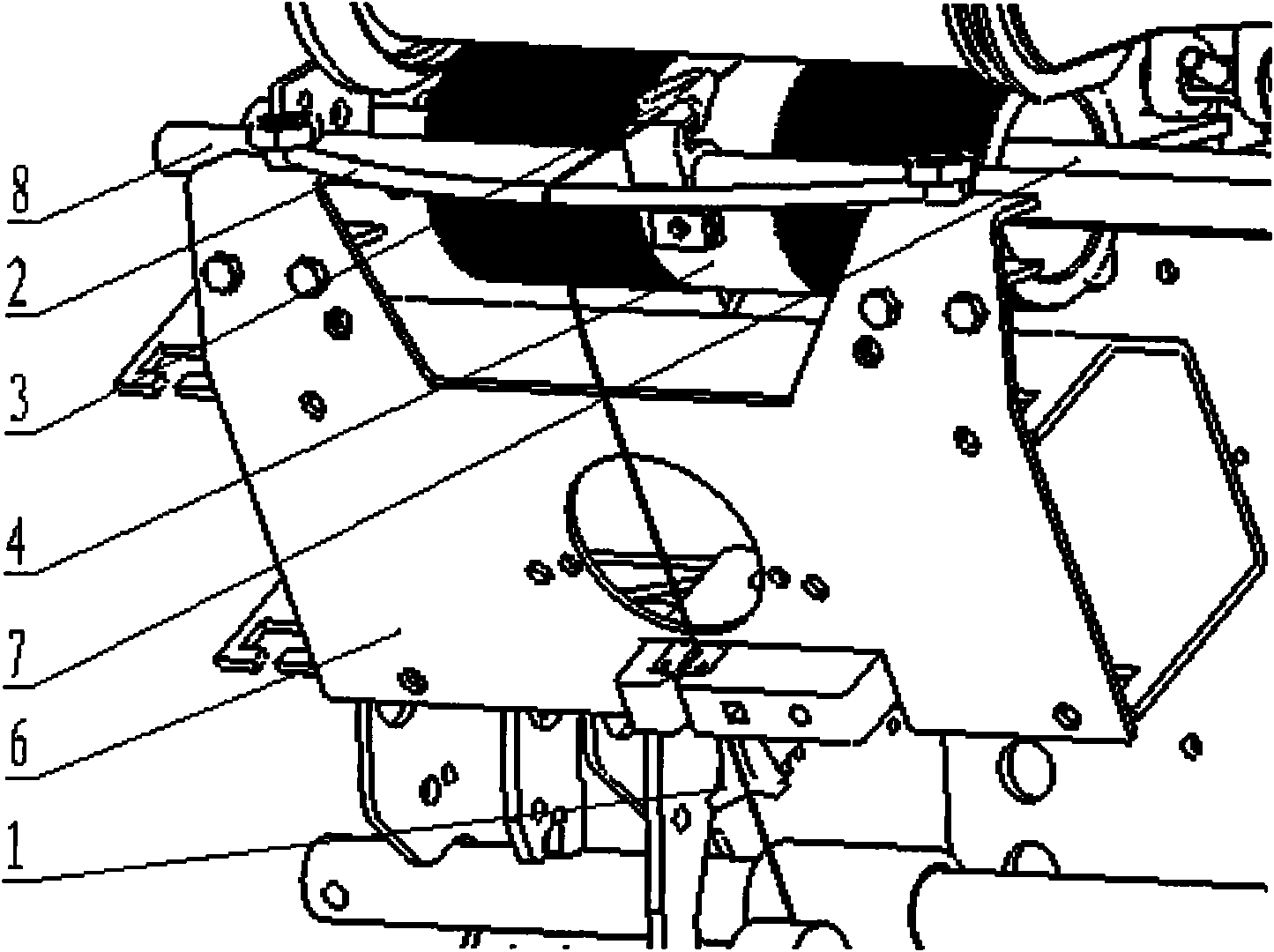

[0014] A constant tension device for a rotor spinning machine, which includes a yarn suction nozzle 1, an arc-shaped yarn guide rod 2, a yarn guide 3, a winding roller 4, a suction pipe 5, a panel 6, a winding roller shaft 7 and a horizontal The reciprocating rod 8 is connected to the yarn suction nozzle 1 and the suction pipe 5, and the suction pipe 5 is connected to the miscellaneous negative pressure channel; the curved yarn guide rod 2 is connected to the panel 6; the yarn guide 3 is connected to the traverse reciprocating rod 8 , The traversing reciprocating rod 8 is connected with the cam of the cam box; the winding roller 4 is connected with the winding roller shaft 7, and the winding roller shaft 7 is connected with the winding frequency conversion motor.

[0015] The radius of the arc yarn guide rod 2 is 175mm, and the chord length is 184mm.

[0016] The shape of the yarn suction nozzle 1 is that the front part is oblong, and the bottom of the mouth has ribs, one long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com