Mowing machine

A technology of frame and adjustment mechanism, applied in the direction of roads, road repair, roads, etc., can solve the problems of saw blade rotation, potential safety hazards, misoperation, etc., and achieve the effect of balanced force and stable and reliable action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

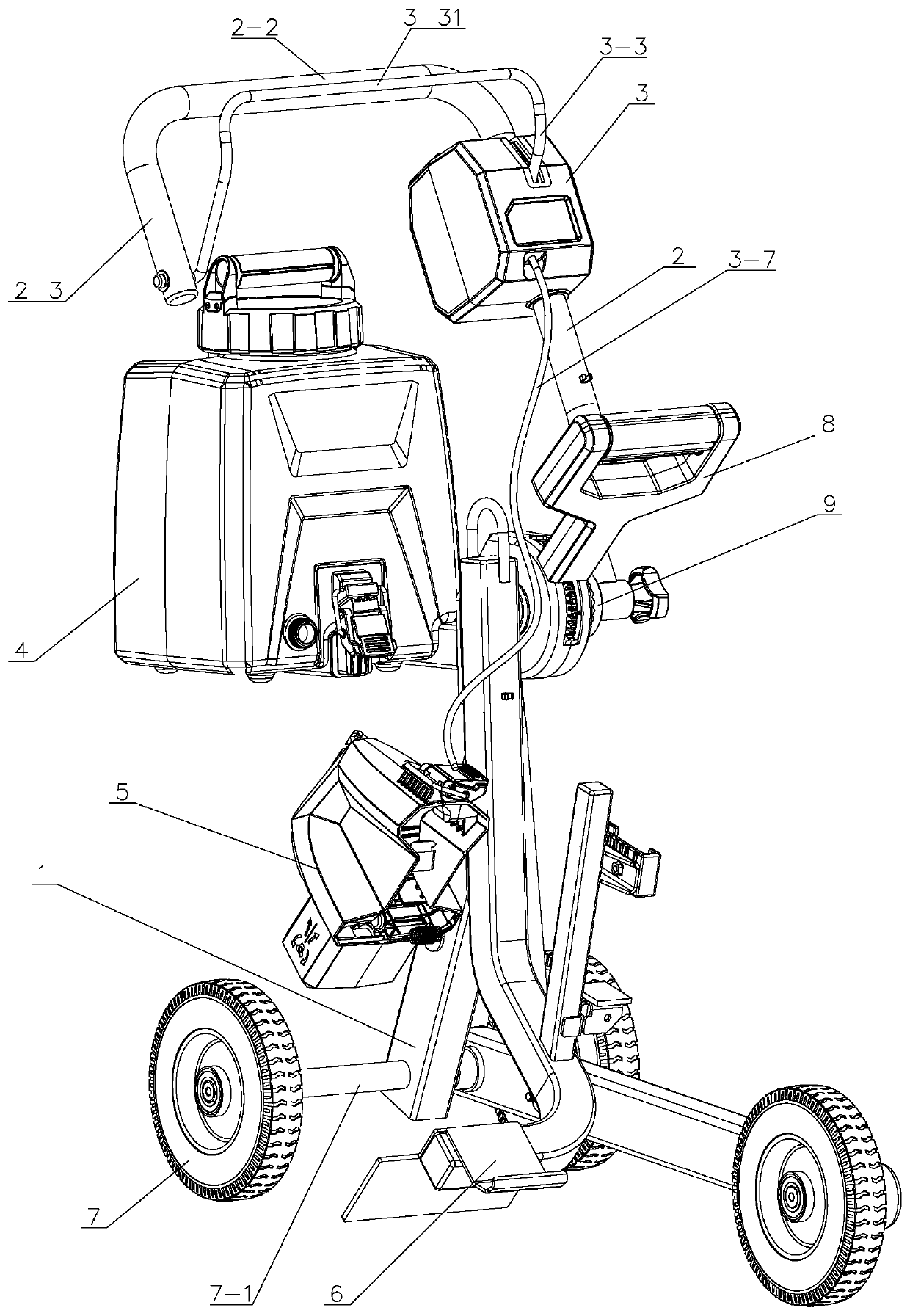

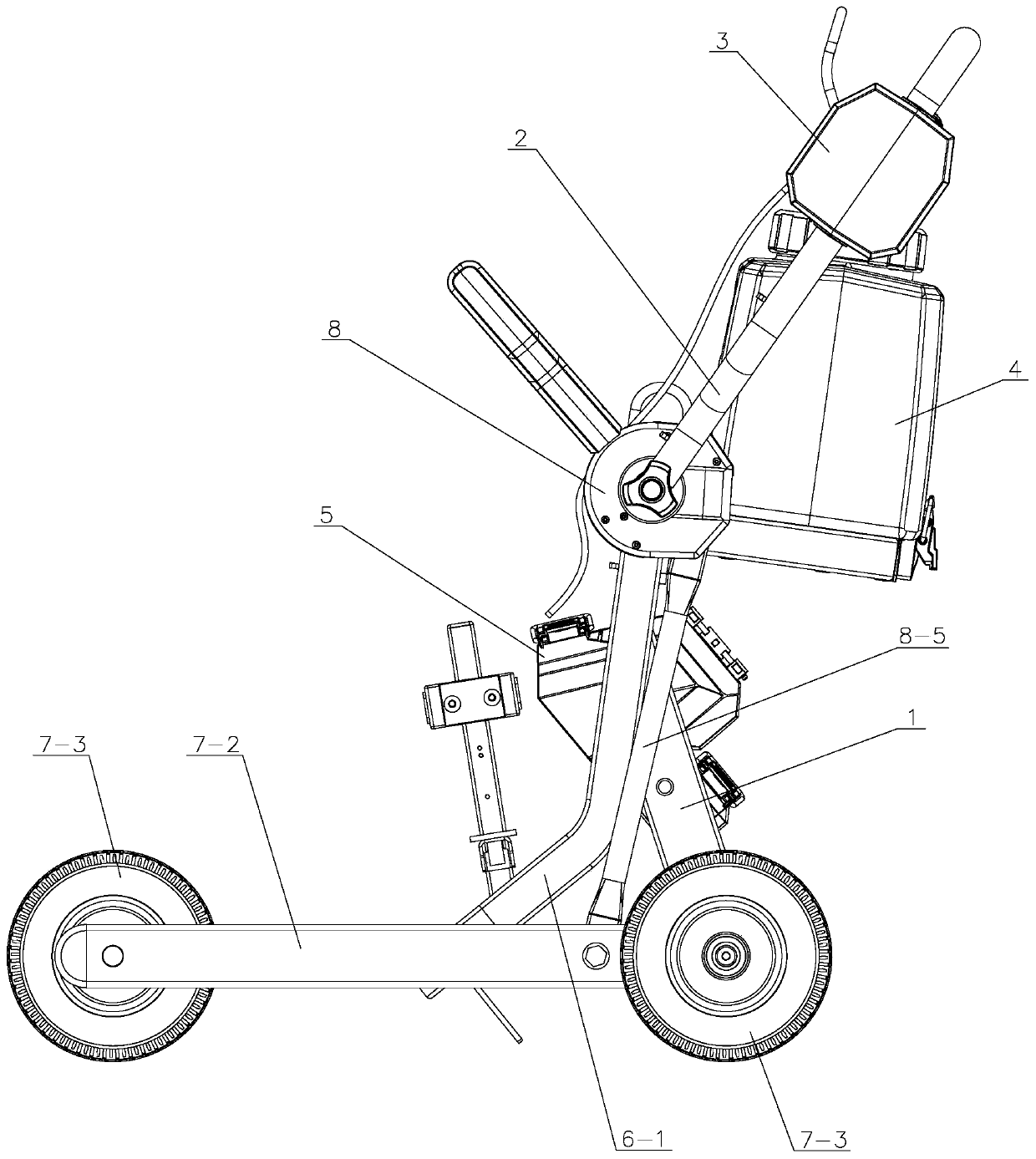

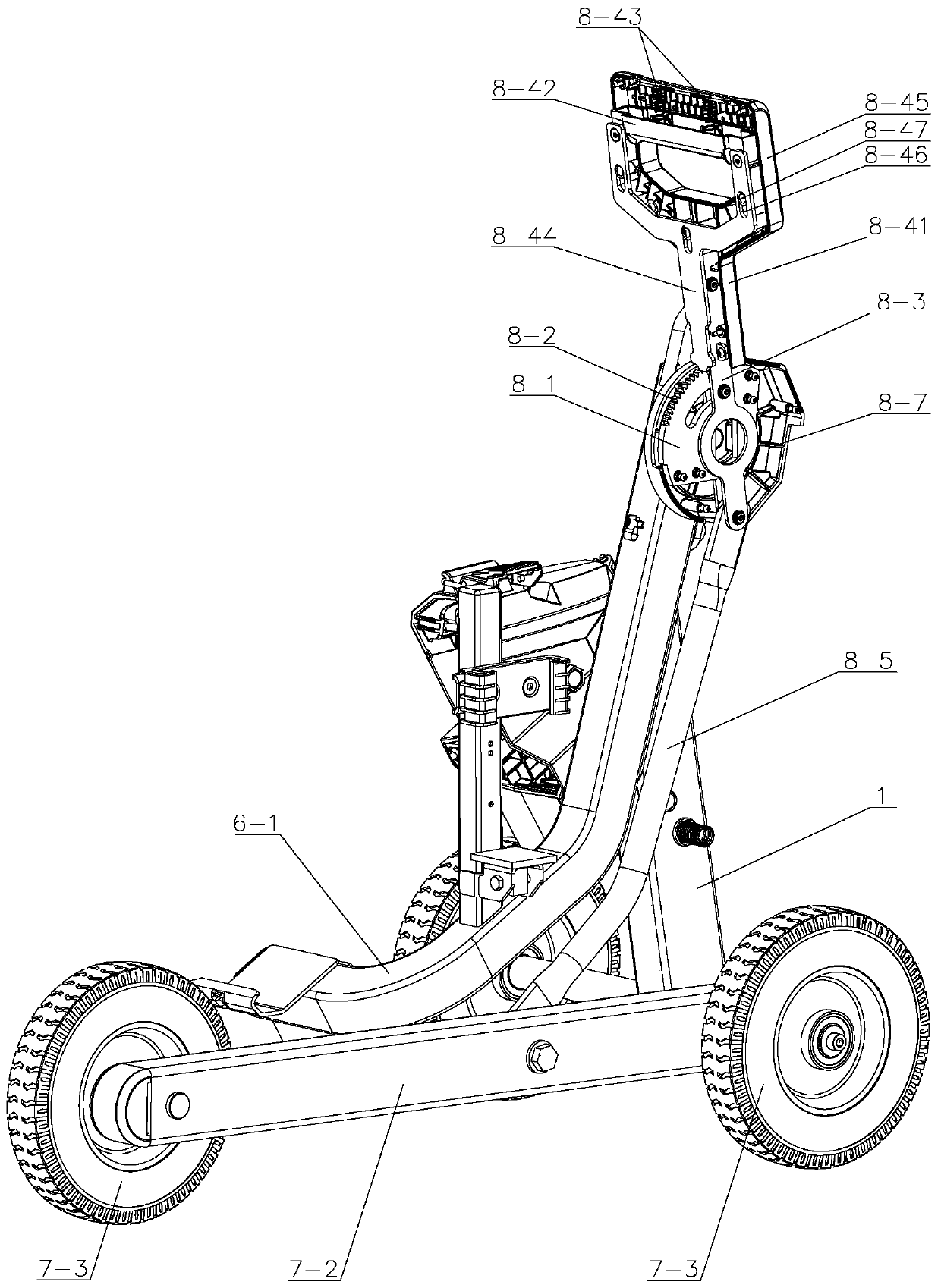

[0054] Such as figure 1 , 2 As shown, a mowing machine whose frame 1 is set up as a vertical and slightly inclined column, and a handrail 2 is connected to the upper end of the frame 1. The handrail 2 is roughly U-shaped, and is mainly composed of vertically arranged handrails 2- 1. The armrest crossbar 2-2 fixedly connected to the upper end of the armrest member 2-1 horizontally, and the vertical armrest short rod 2-3 connected vertically to the other end of the armrest crossbar 2-2.

[0055] On the upper part of the frame 1, there is a horizontally extending support plate with a slot and a lock; the support plate is used to install the water storage mechanism 4, which is mainly composed of a water storage tank and a water pipe. Among them, the water storage tank is placed on the support plate and locked and fixed with a lock, and the water pipe can lead the water out of the water storage tank; water is sprayed in time in the process of cutting the ground and grooving to avoid du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com