Die for preparing integrated electrode for full-vanadium liquid flow energy storage battery and application thereof

An energy storage battery, all-vanadium liquid flow technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of inaccurate positioning, low bonding strength, and poor sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

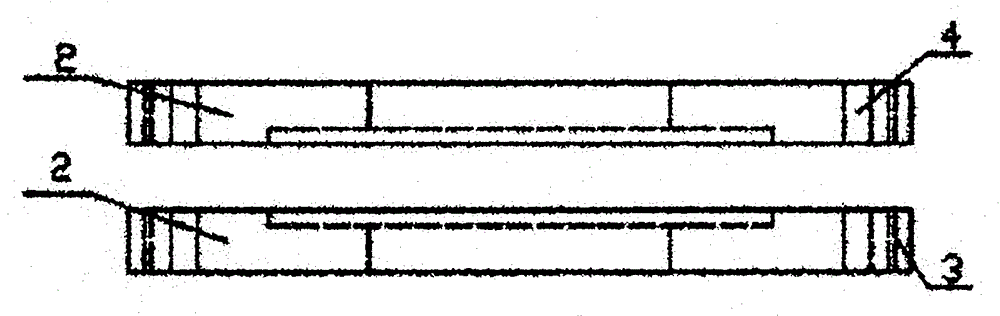

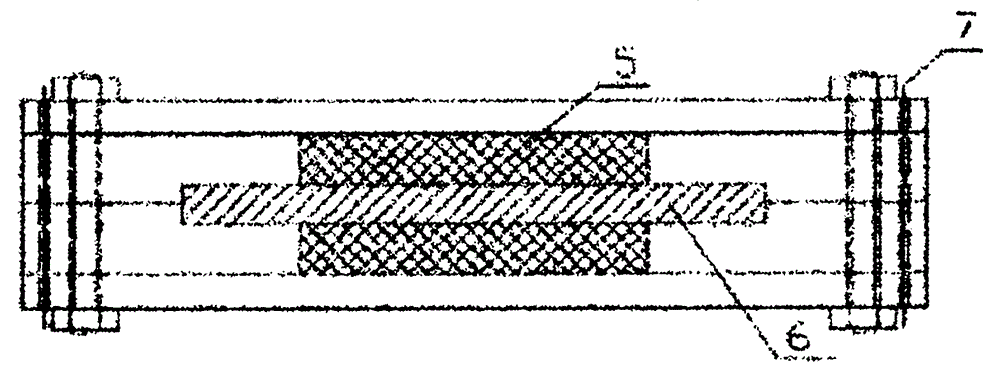

[0044] An all-vanadium redox flow energy storage battery integrated electrode preparation mold, including two rectangular mold frames 2 with the same size and structure. The mold frame 2 is a rectangular metal flat plate. A hole is opened through the metal plate, and the groove sides of the two mold frames are buckled relative to each other to form an all-vanadium redox flow energy storage battery integrated electrode preparation mold. The electrode material (thickness, density) and polyethylene resin-based carbon-plastic composite bipolar plate (thickness, length, width) according to the following Figure 4 Assembled in the manner shown, and then placed the assembled mold on a heat press for heating and pressurization. After the temperature rose to 190°C, the temperature was maintained for 15 minutes. After cooling to normal temperature, the mold is disassembled and demolded.

Embodiment 2

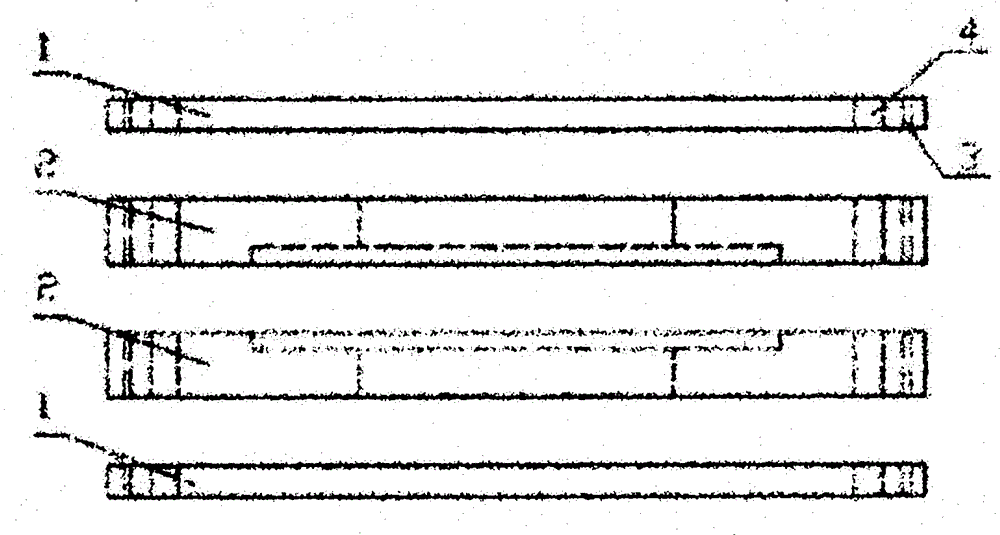

[0046] An all-vanadium redox flow energy storage battery integrated electrode preparation mold, including two rectangular mold frames 2 with the same size and structure. The mold frame 2 is a rectangular metal flat plate. There are holes through the metal plate, and the groove sides of the two mold frames are relatively fastened to form an all-vanadium redox flow energy storage battery integrated electrode preparation mold; at the four corners of the metal plate as the mold frame, respectively Bolt holes 4 are provided.

[0047] Cover plates 1 are arranged on the outer sides of the two mold frames that are relatively fastened respectively. The cover plates 1 are metal flat plates whose size and shape are the same as those of the mold frames 2. Four bolt holes 4 are arranged at corresponding positions of the bolt holes, and the cover plate and the mold frame are connected and fixed through bolts or screws inserted in the bolt holes 4 .

[0048] Two corresponding positioning ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com