A high-pressure hydrogen-facing butterfly valve for coal-to-hydrogen production

A coal-to-hydrogen, high-pressure technology, applied in valve lifts, valve details, valve devices, etc., can solve the problem that the valve plate cannot be opened, and achieve the effect of preventing the sliding bearing from being stuck, avoiding the gap, and being sensitive to the action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

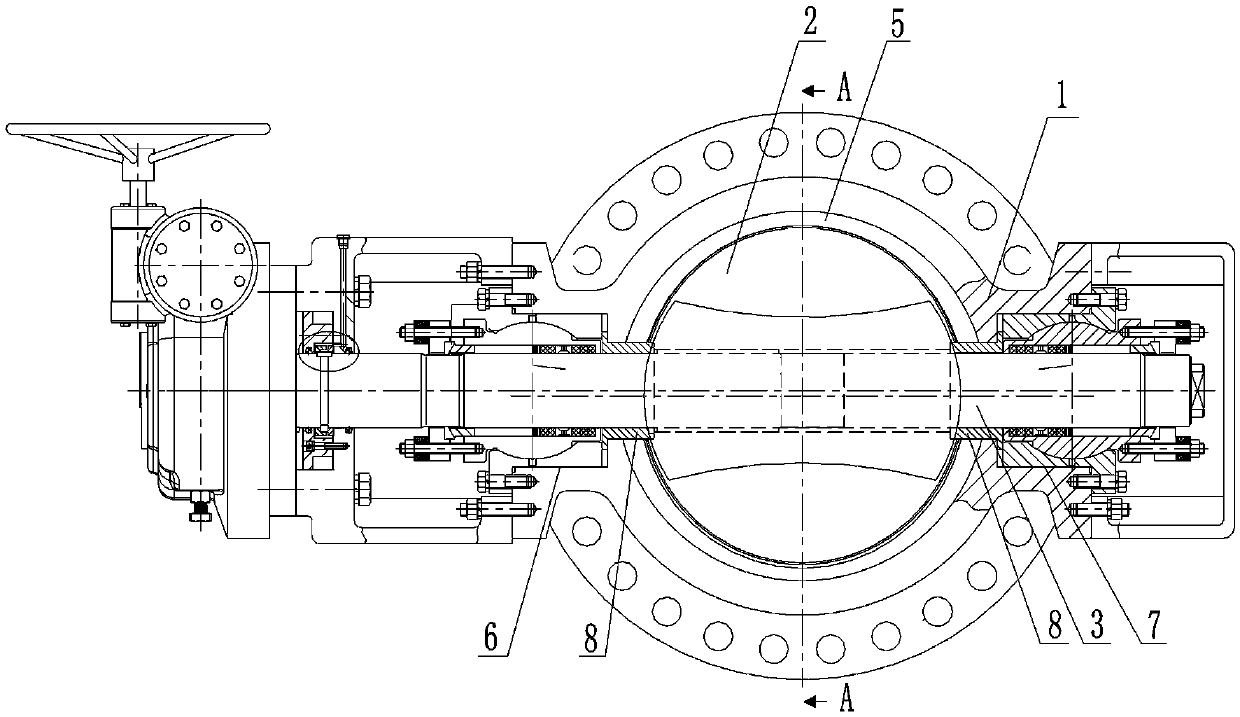

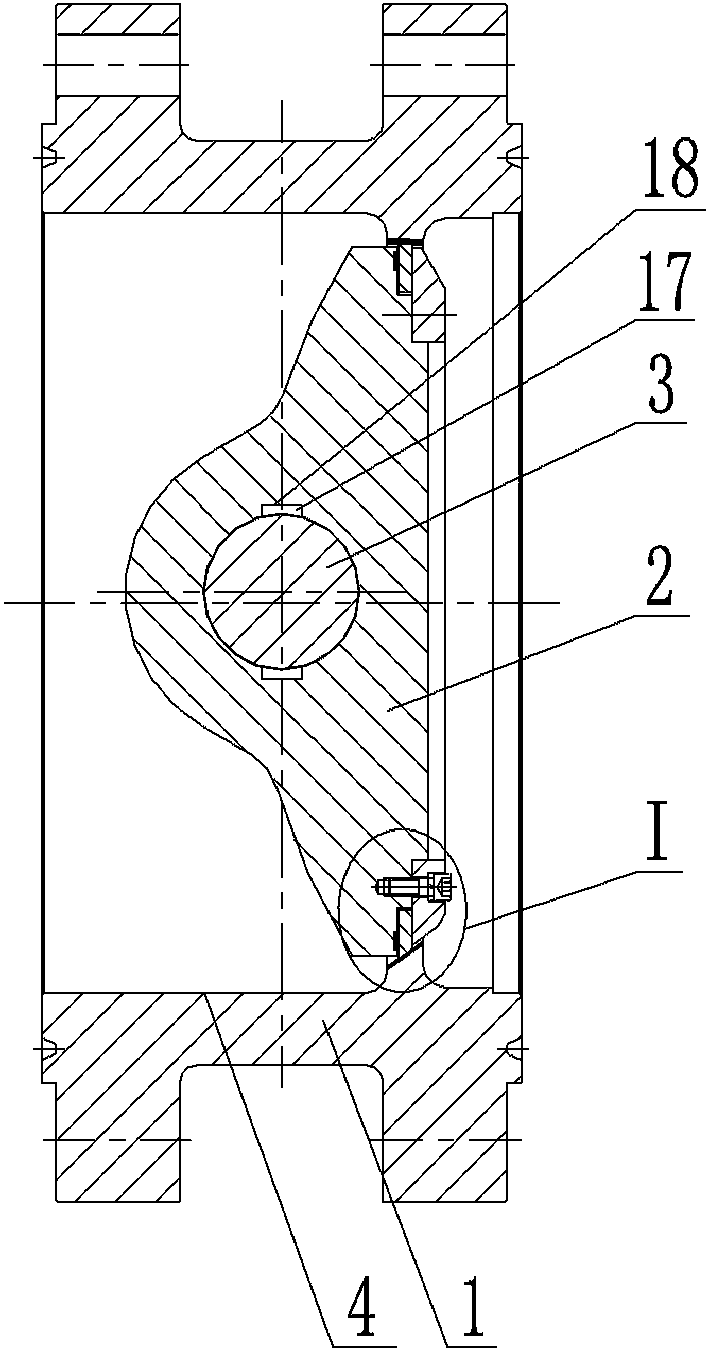

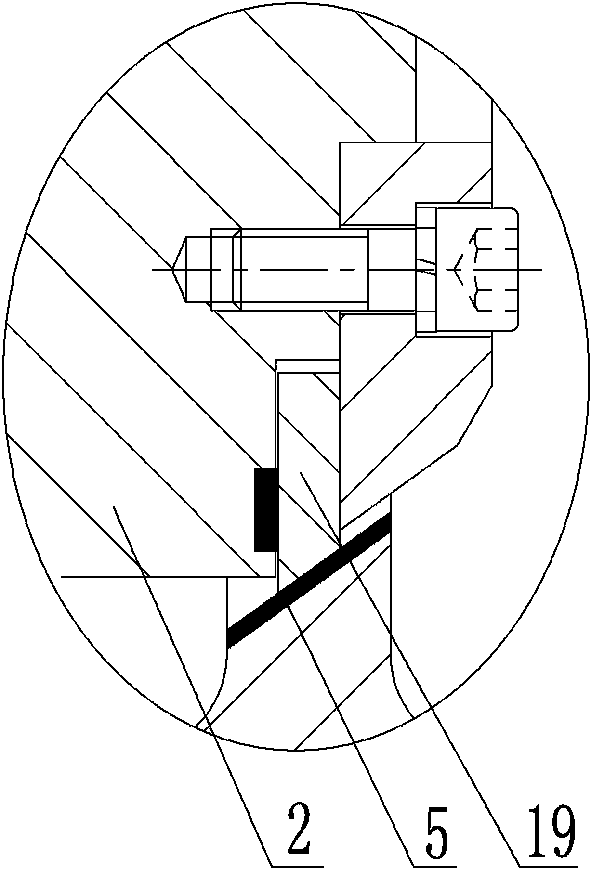

[0020] Such as Figure 1~4 As shown, a coal-to-hydrogen high-pressure hydrogen-facing butterfly valve includes a valve body 1, a valve plate 2 and a valve shaft 3. The valve body 1 is provided with a medium flow channel 4, and the medium flow channel 4 is provided with a tapered The valve seat 5 is characterized in that: the valve body 1 and the left and right sides of the medium flow channel 4 are respectively provided with a step hole a6 and a step hole b7, and a positioning ring 8 is arranged in the small hole of the step hole, and two positioning rings The ring 8 is symmetrically arranged, and the cylindrical surface of the positioning ring 8 is provided with an annular platform 22. The annular platform 22 is pressed between the outer ring 10 of the spherical joint and the shoulder of the step ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com