A halogen-free pickling flux and its preparation method are disclosed

A flux and pickling-free technology, which is applied in the direction of manufacturing tools, welding media, welding/cutting media/materials, etc., to achieve the effects of high brazing efficiency, lower melting point, and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

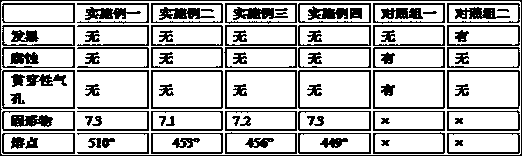

Examples

Embodiment 1

[0011] Embodiment one: a kind of halogen-free pickling-free flux, which flux comprises 55 parts by weight of trimethyl borate, 35 parts of methyl alcohol, 15 parts of water, 3 parts of sodium tetraborate and 2 parts parts of boric acid.

Embodiment 2

[0012] Embodiment two: a kind of halogen-free pickling-free flux, this flux comprises the trimethyl borate that is 55 parts by weight, the methyl alcohol of 35 parts, the water of 15 parts, the sodium tetraborate of 3 parts, 2 parts of boric acid and 3 parts of potassium tetraborate.

Embodiment 3

[0013] Embodiment three: a halogen-free pickling-free flux, the flux comprising 55 parts by weight of trimethyl borate, 35 parts of methanol, 15 parts of water, 3 parts of sodium tetraborate, 2 parts of boric acid and 5 parts of potassium tetraborate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com