Supersonic soldering aluminum coil and its production method

A manufacturing method and ultrasonic technology, applied in manufacturing tools, semiconductor/solid-state device manufacturing, welding equipment, etc., can solve the problems of complicated operation procedures, increased welding defect rate, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings and examples. In describing the present invention, if a specific description of known related content or functions may obscure the gist of the present invention, the detailed description will be omitted.

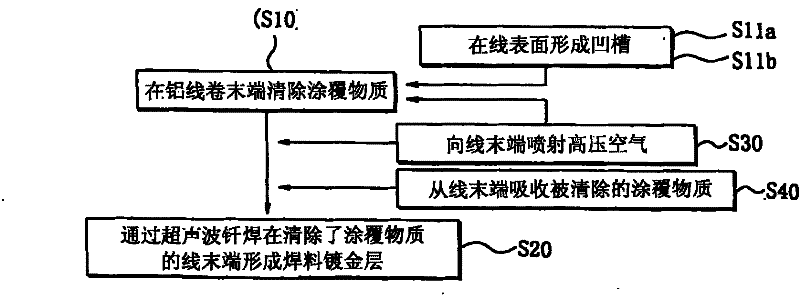

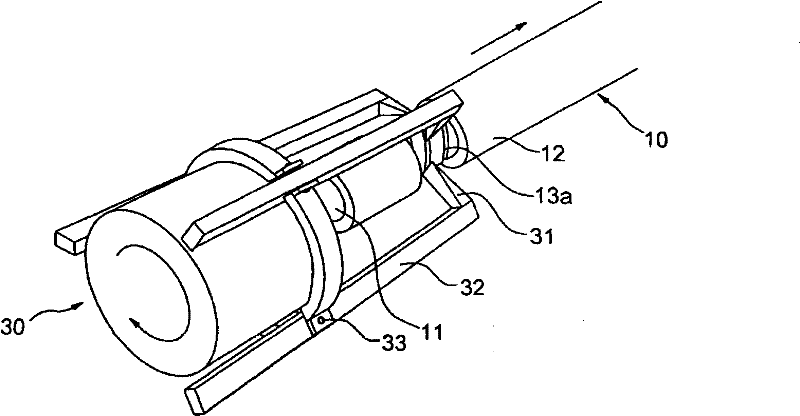

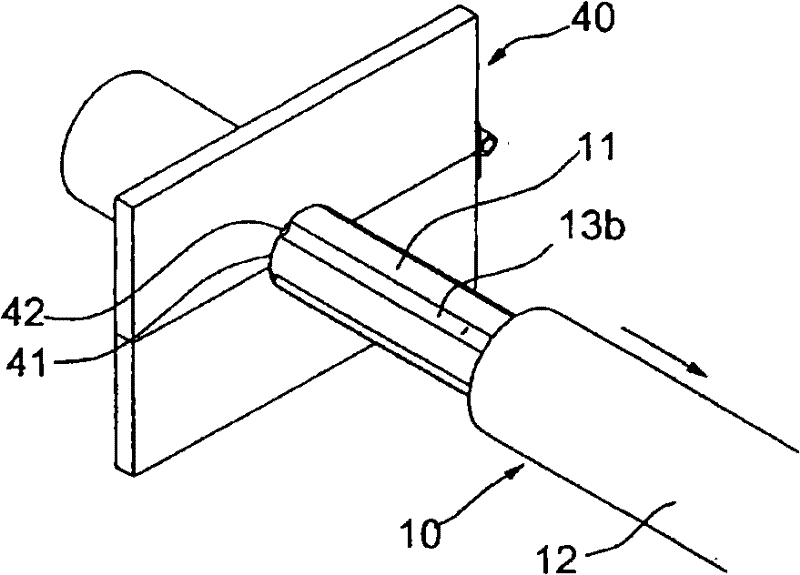

[0027] According to the ultrasonic brazing aluminum coil manufacturing method of the preferred embodiment of the present invention, the present invention includes the following steps: the first step (S10), such as figure 1 The coating substance (12) at the end of the clear wire coil (10) shown; the second step (S20), ultrasonic brazing is carried out to the end of the wire (11) that has removed the coating substance (12) and forms a solder gold-plated layer (20).

[0028] In the first step (S10), the coating substance (12) at the end of the wire coil (10) coated with an insulating substance such as enamel or epoxy resin is removed, although the coating substance (12) can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com