Ink and method adopting ink to prepare conductive line

A technology of conductive lines and inks, applied in printed circuits, printed circuits, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of poor conductivity, high cost, and uneven distribution, and achieve enhanced conductivity, thickness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

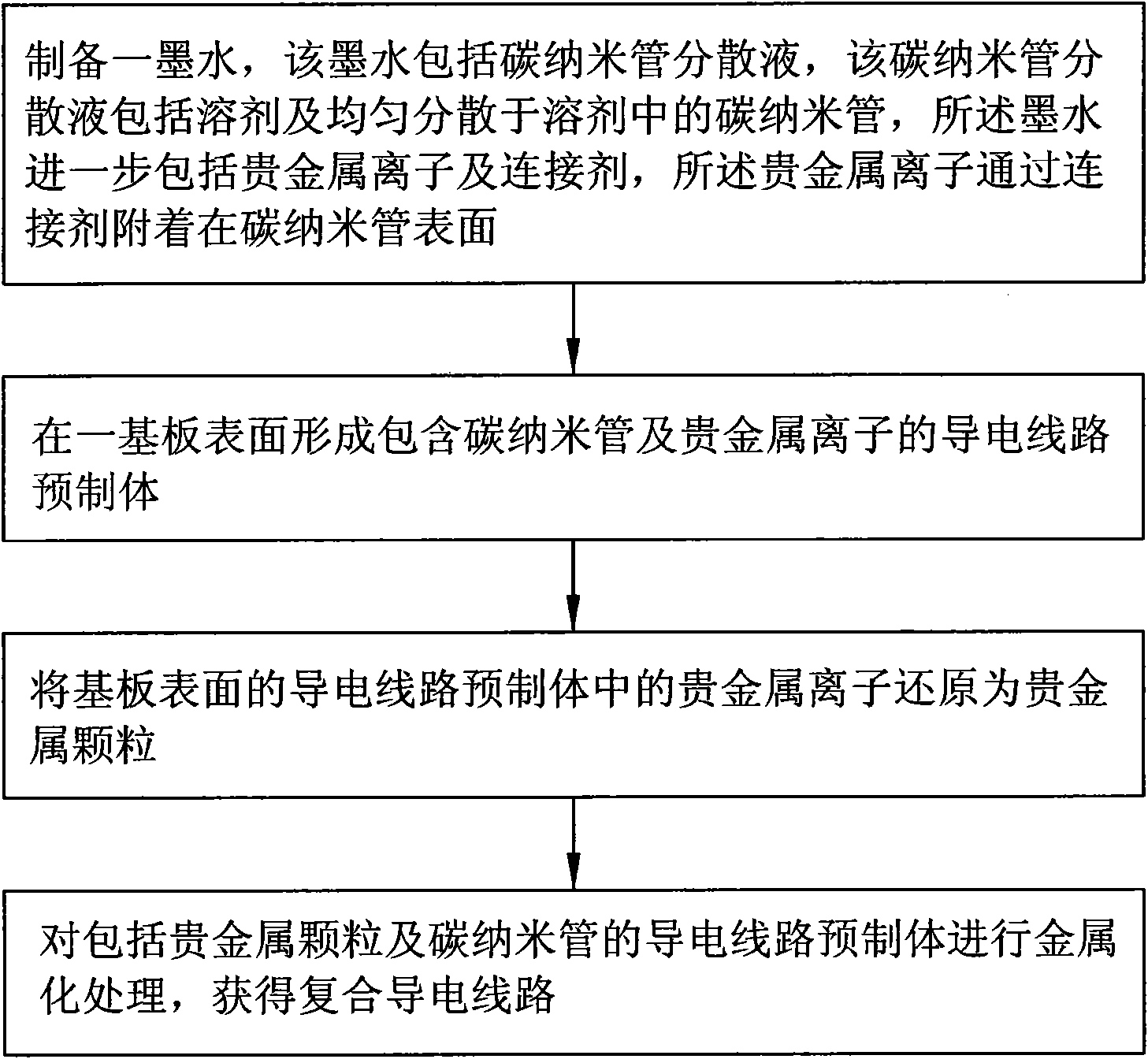

Method used

Image

Examples

Embodiment Construction

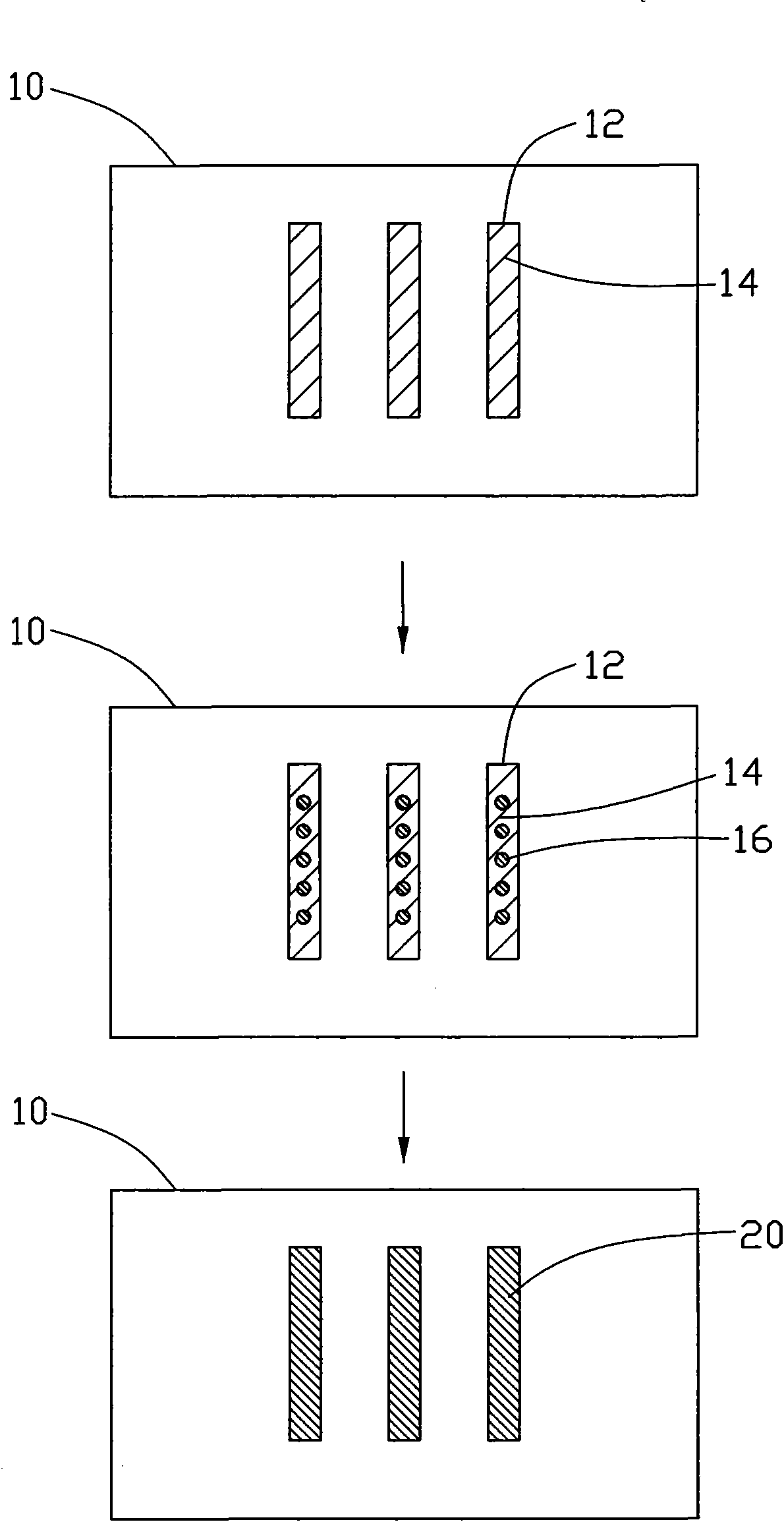

[0015] The ink provided by the present invention and the method for preparing a conductive circuit using the ink will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0016] An embodiment of the present invention provides an ink, the components of which include: noble metal ions, carbon nanotubes, solvents, viscosity modifiers, surfactants and linking agents. Wherein, the mass percentage of the noble metal ion is 1% to 55%, the mass percentage of the carbon nanotube is 0.2 to 5%, the mass percentage of the solvent is 50 to 80%, and the mass percentage of the viscosity modifier 0.1-30%, the mass percentage of the surfactant is 0.1-5%, and the mass percentage of the linking agent is 0.1-30%. Furthermore, a certain amount of humectant can also be added to the ink, and the mass percentage of the humectant is 0.1-40%.

[0017] The noble metal ions may be gold ions, silver ions, palladium ions or platinum ions. In the emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com