Novel steel slag composite soil road base material and preparation method thereof

A technology for road base and base material, applied in the field of new steel slag mixed soil road base material and preparation, can solve problems such as poor stability, and achieve the effects of low expansion rate, good water stability and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

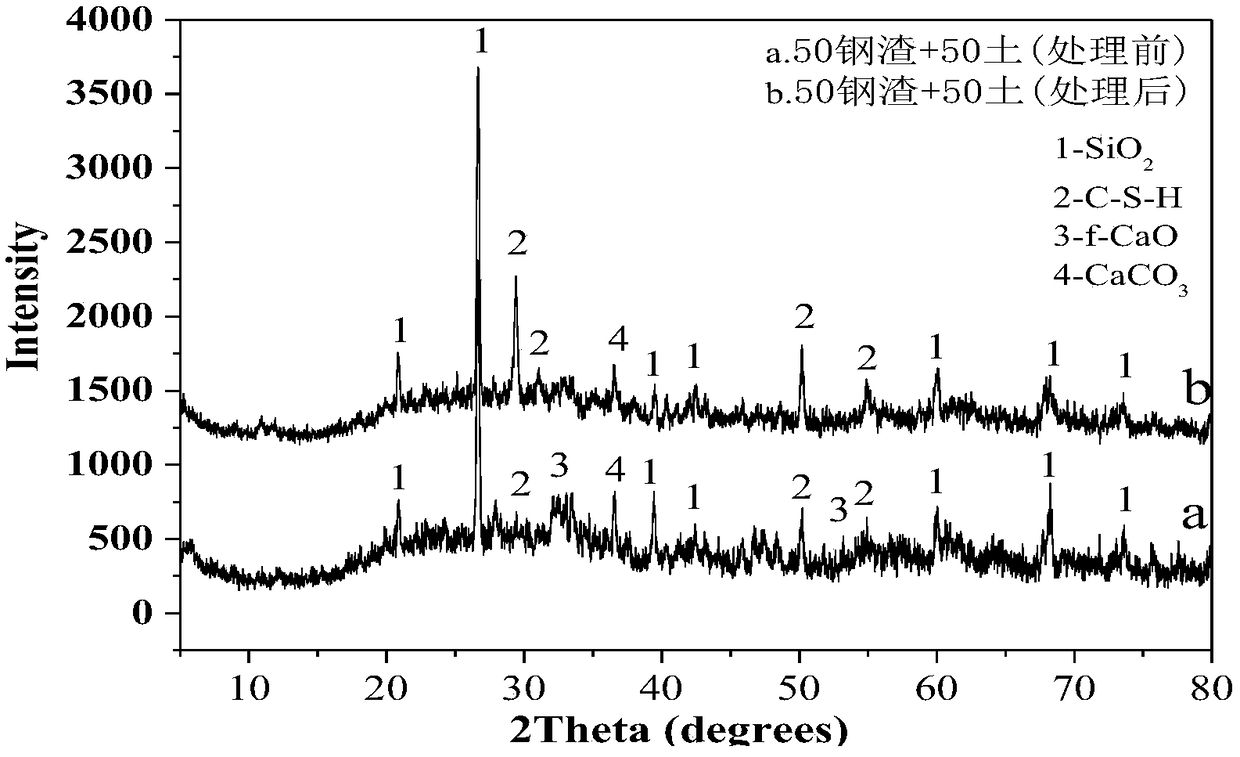

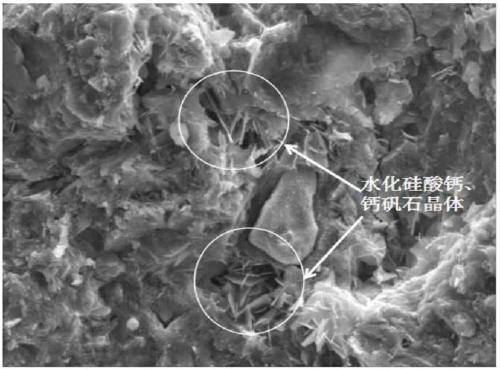

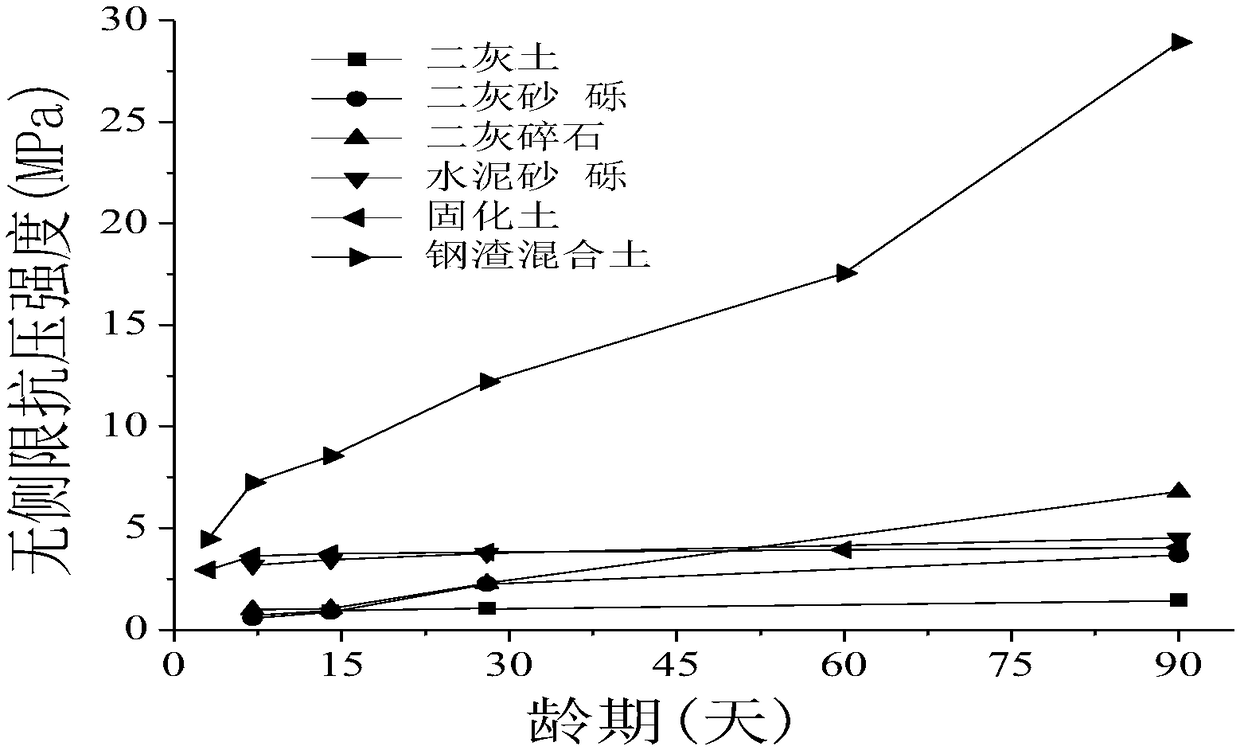

[0035] Select 50 parts of steel slag, 50 parts of soil, 3 parts of cement, 40 parts of compounding agent and 0.02 part of modifier, and prepare a new type of steel slag mixed soil road base material according to the following steps:

[0036] 1) After mixing steel slag, soil, cement and compounding agent, conduct a compaction test to measure the optimum moisture content;

[0037] 2) Screening the unaged steel slag for particle size, and crushing if the particle size is greater than 3.0 cm;

[0038] 3) weighing each component according to parts by weight, wherein the steel slag particle size is not more than 3.0cm;

[0039] 4) Spray the steel slag and the composite agent with tap water with a total water content of 50%, mix and mix them to make them fully contact, and obtain the slag powder mixture;

[0040] 5) Spray modifier in soil and mix remaining 50% tap water to obtain modified soil;

[0041] 6) mixing the slag-powder mixture and the modified soil for the second time to ...

Embodiment 2

[0050] Select 40 parts of steel slag, 60 parts of soil, 3 parts of cement, 40 parts of compounding agent and 0.020 parts of modifier, and prepare the new steel slag mixed soil road base material according to the following steps:

[0051] 1) After mixing steel slag, soil, cement and compounding agent, conduct a compaction test to measure the optimum moisture content;

[0052] 2) Screening the unaged steel slag for particle size, and crushing if the particle size is greater than 3.0 cm;

[0053] 3) weighing each component according to parts by weight, wherein the steel slag particle size is not more than 3.0cm;

[0054] 4) Spray the steel slag and the composite agent with tap water with a total water content of 50%, mix and mix them to make them fully contact, and obtain the slag powder mixture;

[0055] 5) Spray modifier in soil and mix remaining 50% tap water to obtain modified soil;

[0056] 6) mixing the slag-powder mixture and the modified soil for the second time to obta...

Embodiment 3

[0064] Select 50 parts of steel slag, 50 parts of soil, 3 parts of cement, 30 parts of compounding agent and 0.02 part of modifier, and prepare a new type of steel slag mixed soil road base material according to the following steps:

[0065] 1) After mixing steel slag, soil, cement and compounding agent, conduct a compaction test to measure the optimum moisture content;

[0066] 2) Screening the unaged steel slag for particle size, and crushing if the particle size is greater than 3.0 cm;

[0067] 3) weighing each component according to parts by weight, wherein the steel slag particle size is not more than 3.0cm;

[0068] 4) Spray the steel slag and the composite agent with tap water with a total water content of 50%, mix and mix them to make them fully contact, and obtain the slag powder mixture;

[0069] 5) Spray modifier in soil and mix remaining 50% tap water to obtain modified soil;

[0070] 6) mixing the slag-powder mixture and the modified soil for the second time to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com