ZIF-8@MCM-41 molecular sieve and preparation method thereof

A technology of MCM-41 and ZIF-8, applied in chemical instruments and methods, other chemical processes, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem that zeolite imidazolate framework materials cannot withstand temperature and are easy to decompose , limited application and other issues, to achieve the effect of good porosity, high chemical stability and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

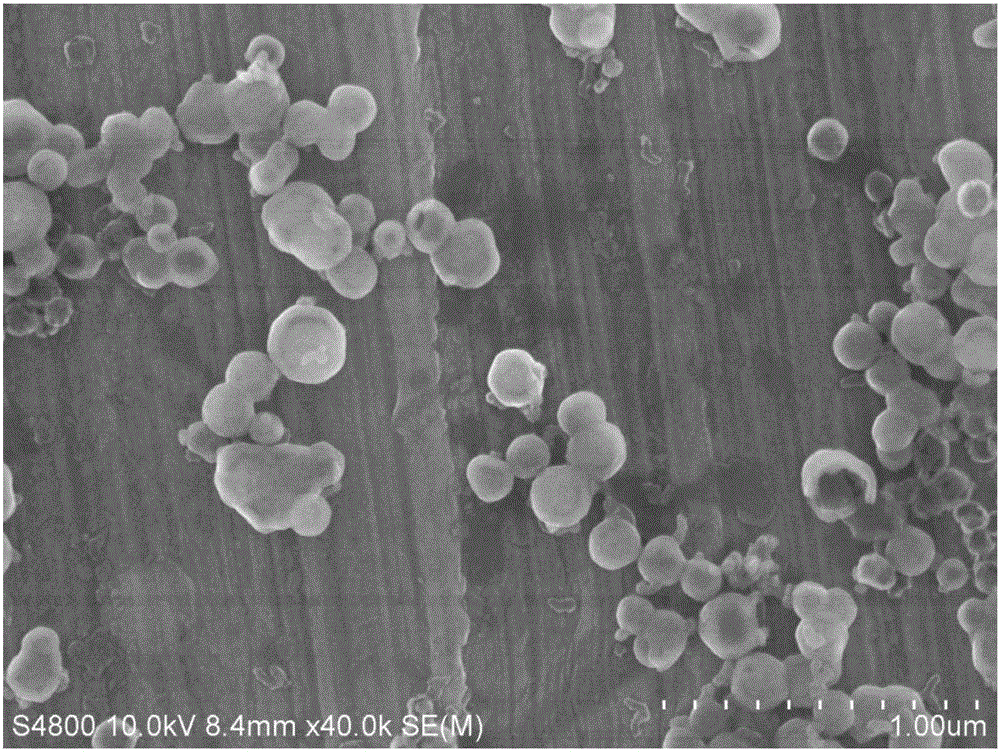

[0025] Dissolve 0.585g of zinc nitrate hexahydrate in 4g of deionized water to make a zinc nitrate solution, dissolve 11.35g of 2-methylimidazole in 40g of deionized water to make a 2-methylimidazole solution, mix the two and then stir for 0.5 h, centrifuged, washed and dried to obtain white powder ZIF-8 particles. Such as Figure 5 Shown is the scanning electron microscope image of the ZIF-8 particles obtained in this example. It can be seen from the figure that the particle size of the ZIF-8 particles is 50-70 nm, and the particle size is uniform.

[0026] Mix 2 g of the obtained ZIF-8 granules with 0.125 g of surfactant CTAB and 20 g of deionized water, then add 0.45 mL of NaOH solution with a concentration of 2 mol / L to adjust the pH to 9, stir and heat at 80 °C for 1 h, slowly dropwise Add 0.625mL tetraethyl orthosilicate and continue the reaction for 8h. After the reaction, let the reaction solution stand still, filter, wash, and dry to obtain a white powder, then heat ...

Embodiment 2

[0029] Dissolve 0.585g of zinc nitrate hexahydrate in 4g of deionized water to make a zinc nitrate solution, dissolve 11.35g of 2-methylimidazole in 40g of deionized water to make a 2-methylimidazole solution, mix the two and then stir for 0.5 h, centrifuged, washed and dried to obtain white powder ZIF-8 particles. Mix 2 g of the obtained ZIF-8 granules with 0.25 g of surfactant CTAB and 80 g of deionized water, then add 0.9 mL of NaOH solution with a concentration of 2 mol / L to adjust the pH to 10, stir and heat at 80 ° C for 1 h, slowly dropwise Add 0.625mL tetraethyl orthosilicate and continue the reaction for 8h. After the reaction, let the reaction solution stand still, filter, wash, and dry to obtain a white powder, then heat the white powder to reflux in 50mL of ethanol to remove the surfactant CTAB, and finally Stand still, wash and dry to obtain white powder ZIF-8@MCM-41 molecular sieve.

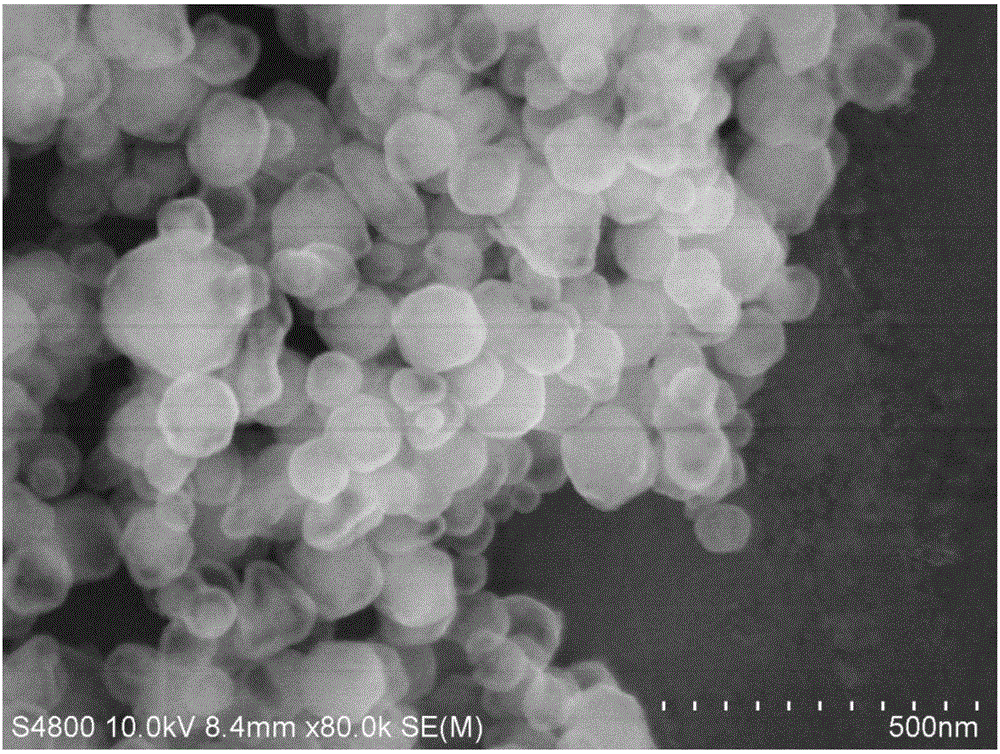

[0030] figure 2 It is a scanning electron microscope image of the product ob...

Embodiment 3

[0032] Dissolve 0.585g of zinc nitrate hexahydrate in 4g of deionized water to make a zinc nitrate solution, dissolve 11.35g of 2-methylimidazole in 40g of deionized water to make a 2-methylimidazole solution, mix the two and then stir for 0.5 h, centrifuged, washed and dried to obtain white powder ZIF-8 particles. Mix 2 g of the obtained ZIF-8 granules with 0.5 g of surfactant CTAB and 200 g of deionized water, then add 1.8 mL of NaOH solution with a concentration of 2 mol / L to adjust the pH to 10, stir and heat at 80 ° C for 1 h, slowly dropwise Add 0.625mL tetraethyl orthosilicate and continue the reaction for 8h. After the reaction, let the reaction solution stand still, filter, wash, and dry to obtain a white powder, then heat the white powder to reflux in 50mL of ethanol to remove the surfactant CTAB, and finally Stand still, wash and dry to obtain white powder ZIF-8@MCM-41 molecular sieve.

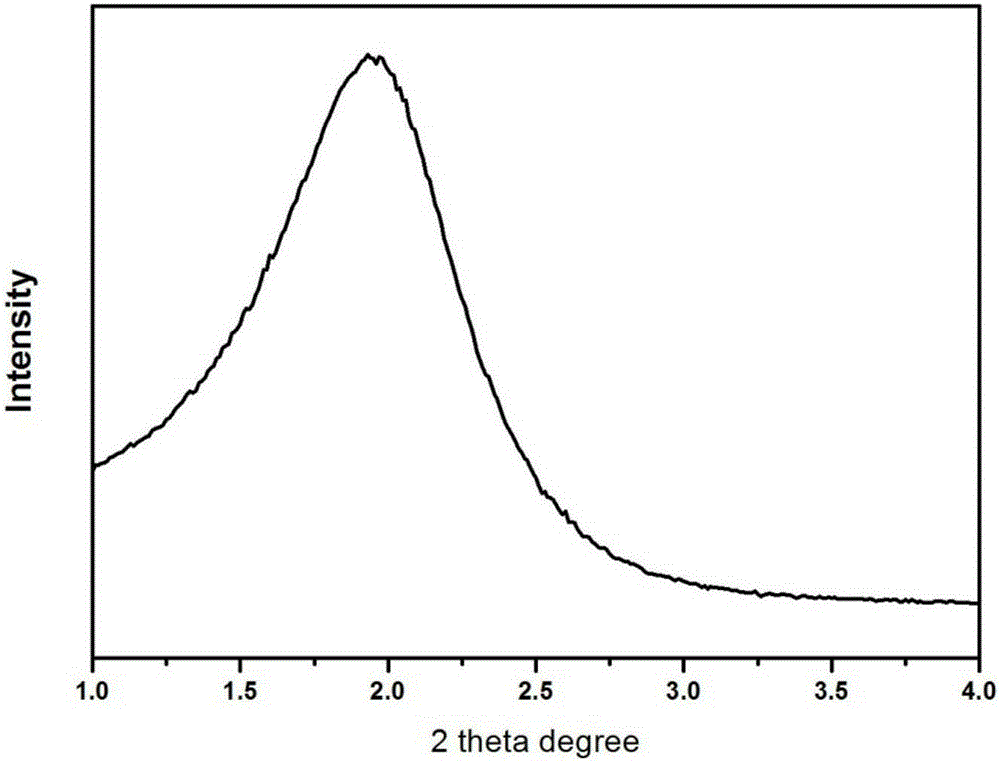

[0033] Figure 4 It is a scanning electron microscope image of the product ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com