Dryer material lifting mechanism

A dryer and lifting plate technology, which is applied to drying, drying solid materials, lighting and heating equipment, etc., can solve the problems affecting the normal operation and use effect of the equipment, the continuous operation time of the equipment is short, and the maintenance cost is high. The effect of increased contact time, increased contact area, and increased drying output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

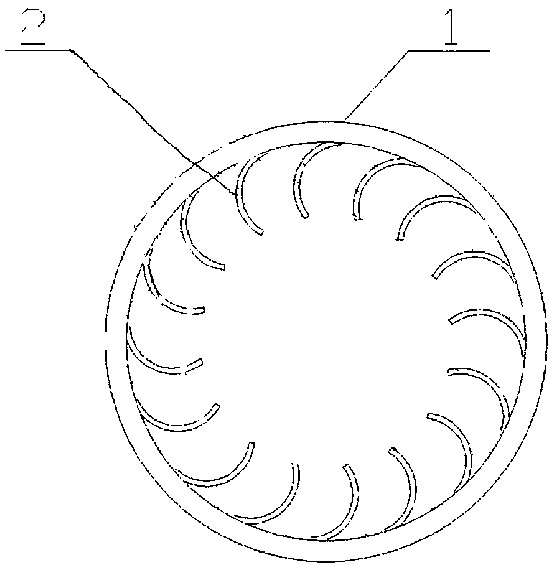

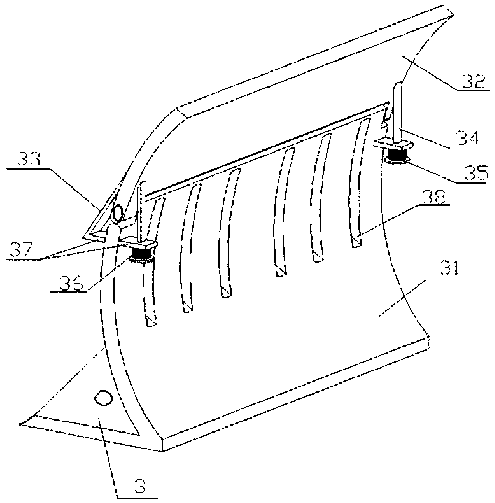

[0021] Such as Figure 1-2 As shown, a dryer lifting mechanism includes 24 sets of lifting assemblies 2 arranged at equal intervals along the axial direction of the drum 1, and each group of lifting assemblies 2 includes eight 8 sets of lifting assemblies arranged at equal intervals along the axial direction of the rotating drum 1. One lifting plate, the lifting plates of the adjacent lifting components 2 are arranged alternately, the angle between the connection point between the adjacent lifting plates of the adjacent lifting components 2 and the inner wall of the drum 1 and the axis of the drum 1 is 22.5°.

[0022] The lifting plate is arc-shaped, including a movable plate 32 and a fixed plate 31 connected to the inner wall of the drum. The bottom of the fixed plate 31 is connected with the inner wall of the drum 1 by solid welding, and the top is extended along the same curvature at the midpoint of its length. There are lugs, the bottom of the movable plate 32 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com