Coplanar multicylinder direct-driving type gas compressing mechanism

A gas compression, direct-acting technology, applied in the direction of machines/engines, liquid displacement machinery, multi-stage pumps, etc., can solve the problems of poor sealing effect, low gas compression efficiency, complex structure, etc., to improve product manufacturability , Improving mechanical efficiency, simplifying the effect of mechanical positioning and guiding mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

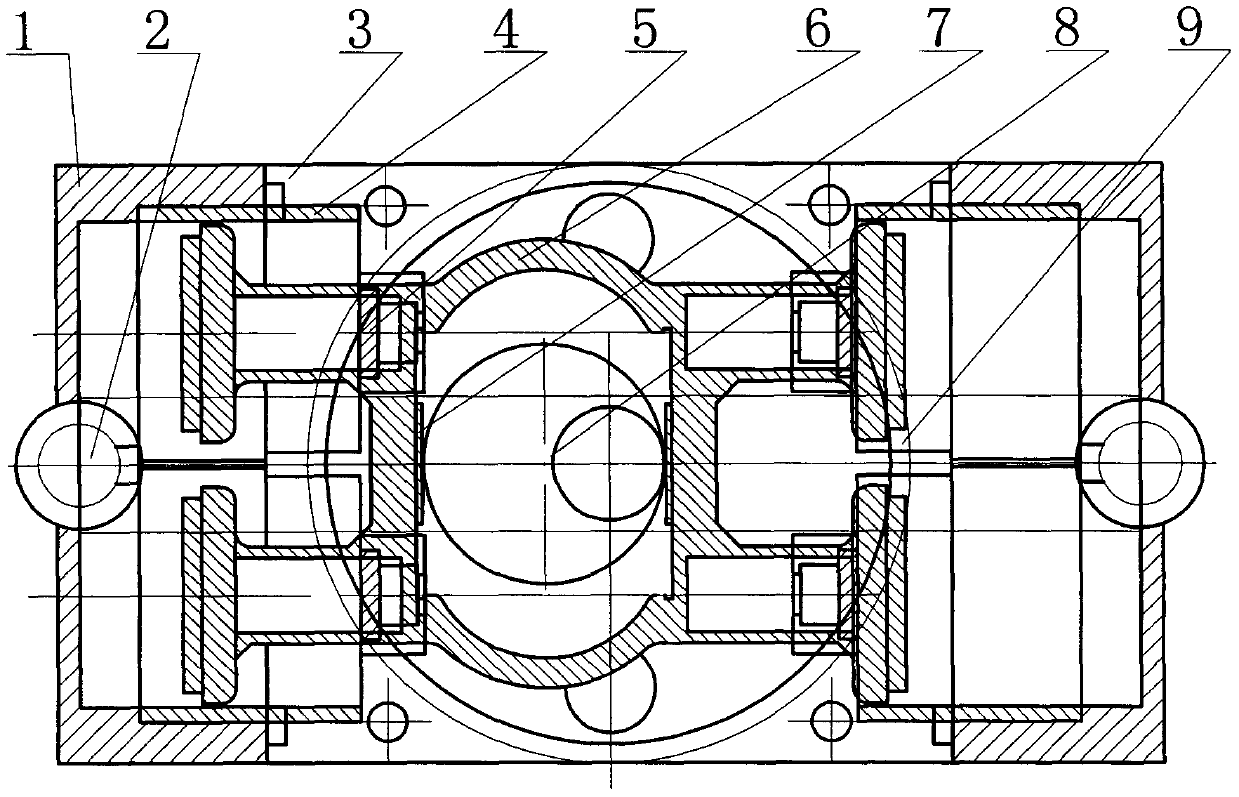

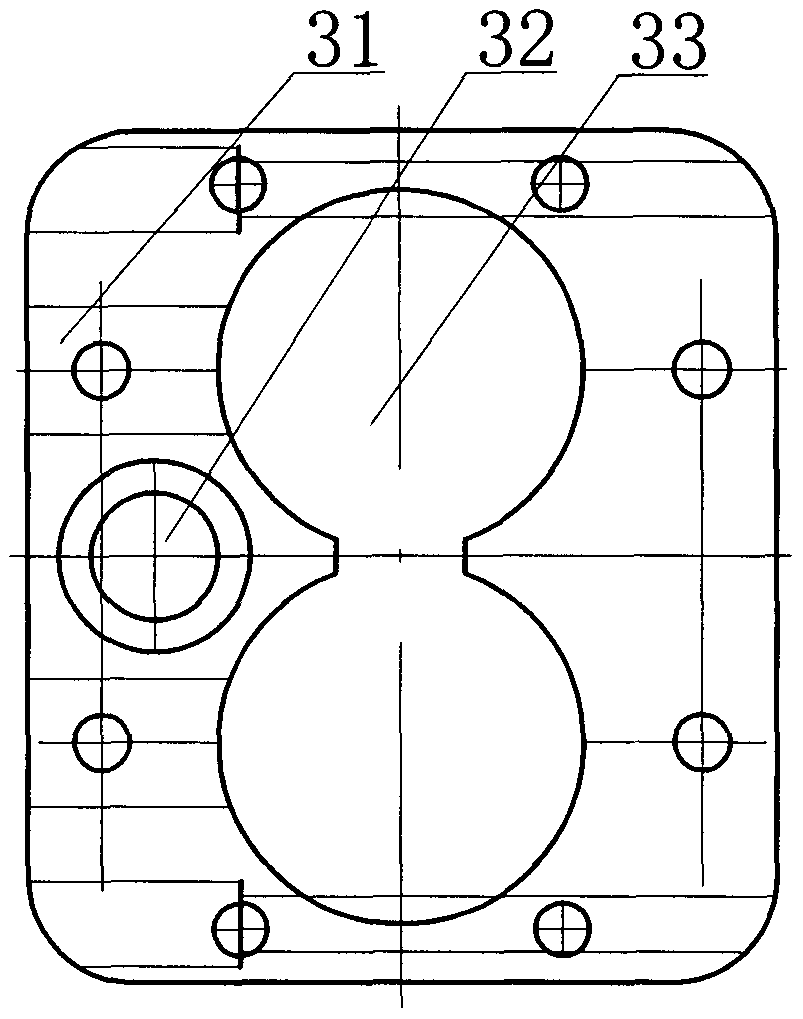

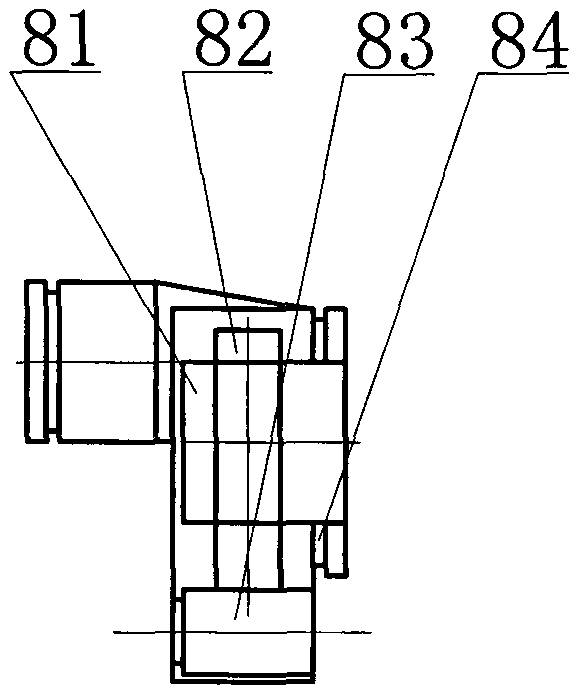

[0012] The same-plane multi-cylinder direct-acting gas compression mechanism of the present invention, as attached figure 1 As shown, it includes: left and right upper and lower cylinder heads (1), cylinder head hole pipe (2), multi-cylinder frame on the same surface (3), cylinder frame air intake hole (31), cylinder frame hole pipe (32), cylinder frame Cylinder liner connection through hole (33), left and right upper and lower cylinder liners (4), compensation spring (5), oblong hole multi-link piston (6), push steel plate positioning rib (7), eccentric shaft counterweight column (8) , motor shaft hole (81), straight pin (82), horizontal pin (83), circlip (84) and motor (9), left and right upper and lower cylinder heads (1), left and right upper and lower cylinder sleeves (4) and long round holes Each center of the rod piston (6) is arranged on a plane, and each left and right cylinder liner (4) is staggered in the left and right sides and up and down. figure 2 As shown, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com