High-efficiency energy-saving nmmo solution concentration system and method

A high-efficiency energy-saving, concentrated system technology, applied in textiles and papermaking, sustainable manufacturing/processing, rayon recycling, etc., can solve the problems that waste heat cannot be recycled, and the conditions for secondary steam utilization are harsh, so as to reduce heat energy consumption, Effect of increasing evaporation intensity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

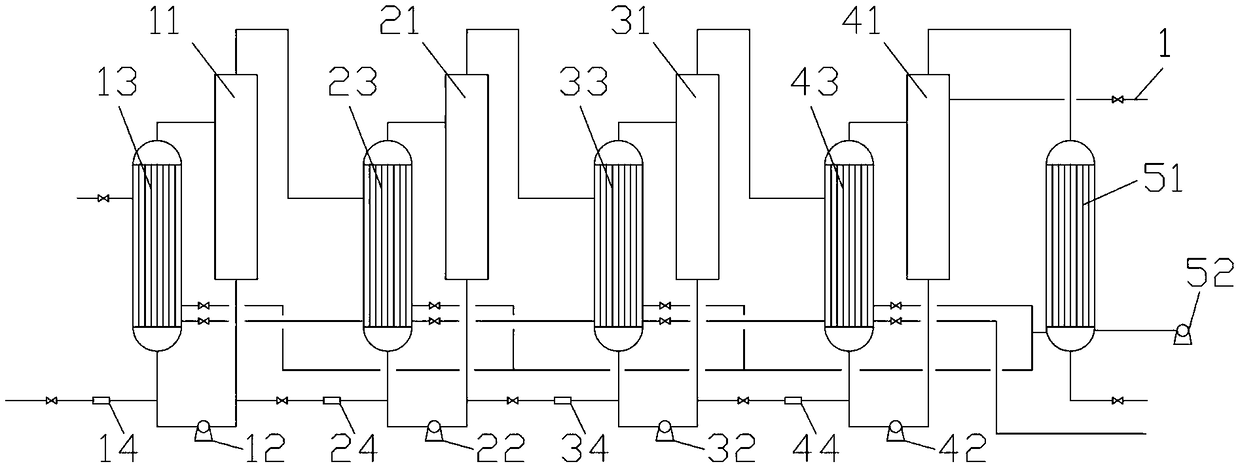

Image

Examples

Embodiment example 1

[0060]Using the four-effect countercurrent decompression evaporation concentration system of the present invention, the technical parameters are: four-effect feeding nmmo concentration 15%, four-effect heating steam temperature 56°C, four-effect evaporation temperature 42°C, four-effect vacuum -94kpa, four-effect outlet The feed concentration is 25%. The three-effect heating steam temperature is 75°C, the three-effect evaporation temperature is 66°C, the three-effect vacuum is -82kpa, and the three-effect output concentration is 45%. The second-effect heating steam temperature is 93°C, the second-effect evaporation temperature is 85°C, the second-effect vacuum is -55kpa, and the second-effect output concentration is 65%. The heating steam temperature of the first effect is 105°C, the evaporation temperature of the first effect is 100°C, the vacuum of the first effect is -20kpa, and the output concentration of the first effect is 83%.

Embodiment example 2

[0062] Using the four-effect countercurrent decompression evaporation concentration system of the present invention, the technical parameters are: four-effect feeding nmmo concentration 18%, four-effect heating steam temperature 57°C, four-effect evaporation temperature 44°C, four-effect vacuum -90kpa, four-effect outlet The feed concentration is 31%. The three-effect heating steam temperature is 78°C, the three-effect evaporation temperature is 67°C, the three-effect vacuum is -83kpa, and the three-effect output concentration is 44%. The second-effect heating steam temperature is 91°C, the second-effect evaporation temperature is 86°C, the second-effect vacuum is -57kpa, and the second-effect output concentration is 63%. The heating steam temperature of the first effect is 105°C, the evaporation temperature of the first effect is 98°C, the vacuum of the first effect is -17kpa, and the output concentration of the first effect is 82%.

Embodiment example 3

[0064] Using the four-effect countercurrent decompression evaporation concentration system of the present invention, the technical parameters are: four-effect feeding nmmo concentration 21%, four-effect heating steam temperature 55°C, four-effect evaporation temperature 40°C, four-effect vacuum -95kpa, four-effect outlet Material concentration 30%. The three-effect heating steam temperature is 79°C, the three-effect evaporation temperature is 67°C, the three-effect vacuum is -83kpa, and the three-effect output concentration is 45%. The second-effect heating steam temperature is 93°C, the second-effect evaporation temperature is 89°C, the second-effect vacuum is -55kpa, and the second-effect output concentration is 64%. The heating steam temperature of the first effect is 107°C, the evaporation temperature of the first effect is 101°C, the vacuum of the first effect is -15kpa, and the output concentration of the first effect is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com