Efficient concentrator

A concentrator, high-efficiency technology, applied in the direction of multi-effect evaporation, evaporator accessories, etc., can solve the problems of increasing production cost, reducing evaporation effect, and deteriorating concentration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

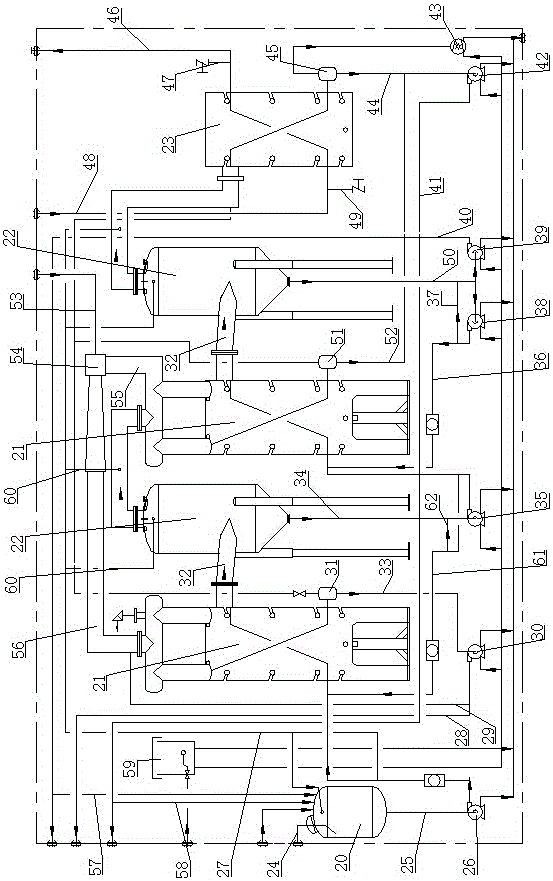

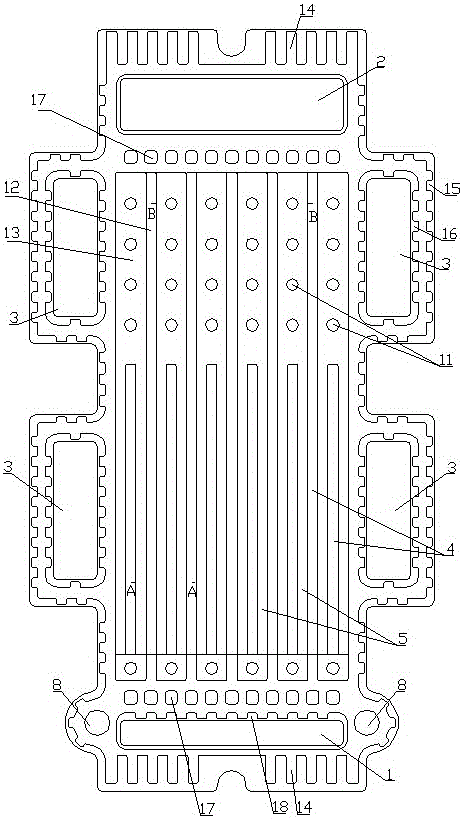

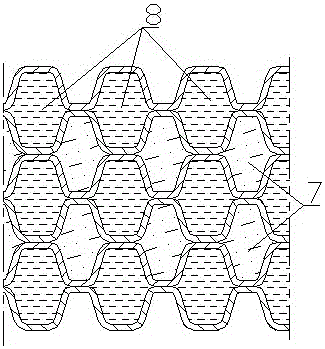

[0027] The high-efficiency concentrator includes a balance tank 20, a separation device, and a plate condenser 23. The feed port of the balance tank 20 is connected with a feed pipe 24, and the discharge port of the balance tank 20 is connected with a discharge pipe 25, and the discharge pipe 25 is installed There is a liquid inlet pump 26, wherein the separation device includes a plate evaporator 21 and a separation tank 22, the steam inlet of the plate evaporator is connected with a steam inlet pipe 56, and the raw material outlet of the plate evaporator is connected with the inlet of the separation tank through a separation pipe 32, separating The pipe is arranged tangentially to the separation tank, and the separation pipe is inclined downward from the feed end to the discharge end, so that the material flows into the separation tank smoothly.

[0028] The separation device in the present invention is two groups or more than two groups, and its pipeline connection structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com