Disordered flowers lavender essential oil and refining method thereof

A technology of lavender essential oil and mixed flowers, which is applied in the field of refining lavender essential oils of mixed flowers, and can solve the problems of poor quality and low yield of essential oils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

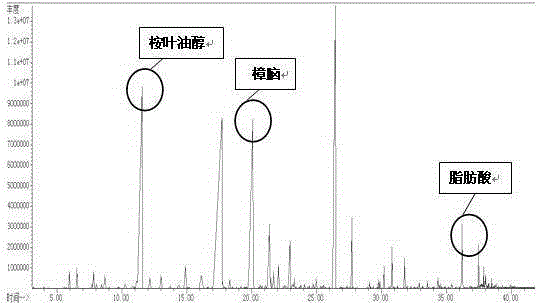

[0017] Pre-freeze the lavender essential oil at -20°C for 2 hours. The pre-frozen lavender essential oil was quickly placed in a low-temperature refrigerated centrifuge, the temperature of the centrifuge was controlled at -10°C, the speed was 10000rpm / min, centrifuged for 20min, and the supernatant was quickly poured out for later use. Pour the supernatant from low-temperature freezing and centrifugation into the evaporating flask of the molecular distillation equipment, and control the preheating temperature to 40°C, the evaporation temperature to 50°C, the cooling temperature to -30°C, the frequency of the peristaltic pump to 10Hz, and the speed of the wiper to be 150rpm / min, the evaporation pressure is 10mbar, and the light components are collected for later use. The light components obtained from a molecular distillation are injected into the evaporating flask of the molecular distillation equipment again, and the preheating temperature is controlled at 50°C, the evaporati...

example 2

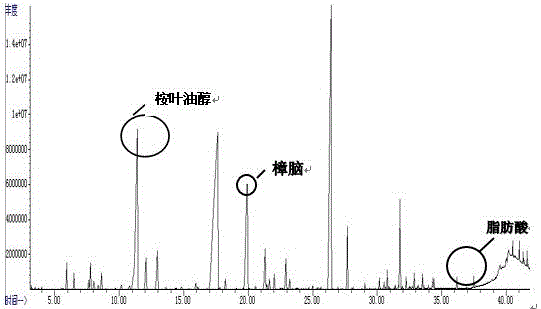

[0019] Pre-freeze the lavender essential oil at -25°C for 4 hours. The pre-frozen lavender essential oil was quickly placed in a low-temperature refrigerated centrifuge, the temperature of the centrifuge was controlled at -20°C, the speed was 15000rpm / min, centrifuged for 15min, and the supernatant was quickly poured out for later use. Pour the supernatant from low-temperature frozen centrifugation into the evaporating flask of the molecular distillation equipment, and control the preheating temperature to 35°C, the evaporation temperature to 55°C, the cooling temperature to -25°C, the frequency of the peristaltic pump to 15Hz, and the speed of the wiper to 180rpm / min, the evaporation pressure is 20mbar, and the light components are collected for future use. The light components obtained from a molecular distillation are injected into the evaporating flask of the molecular distillation equipment again, and the preheating temperature is controlled at 55°C, the evaporation temp...

example 3

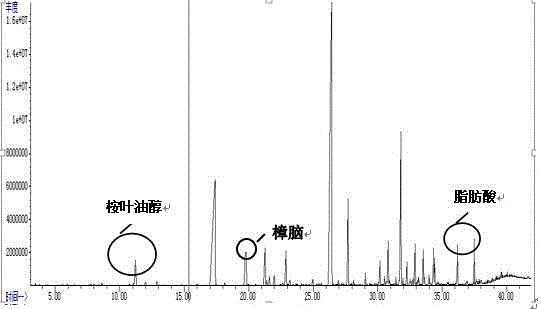

[0021] Pre-freeze the lavender essential oil at -15°C for 8 hours. The pre-frozen lavender essential oil was quickly placed in a low-temperature refrigerated centrifuge, the temperature of the centrifuge was controlled at -15°C, the speed was 12000rpm / min, centrifuged for 30min, and the supernatant was quickly poured out for later use. Pour the supernatant from low-temperature frozen centrifugation into the evaporating flask of the molecular distillation equipment, and control the preheating temperature to 40°C, the evaporation temperature to 60°C, the cooling temperature to -15°C, the frequency of the peristaltic pump to 18Hz, and the speed of the wiper to 160rpm / min, the evaporation pressure is 16mbar, and the light components are collected for later use. The light components obtained from a molecular distillation are injected into the evaporating flask of the molecular distillation equipment again, and the preheating temperature is controlled at 45°C, the evaporation tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com