Vacuum drying method of carbon dioxide full base degradation plastic-polypropylidene carbonate and its device

A technology for polypropylene carbonate and degradable plastics, applied in the field of degradable plastic drying, can solve the problems of drying temperature not exceeding the material denaturation temperature, drying exhaust gas not being directly discharged, drying moisture not being able to be recovered, etc. High yield, not easy to dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

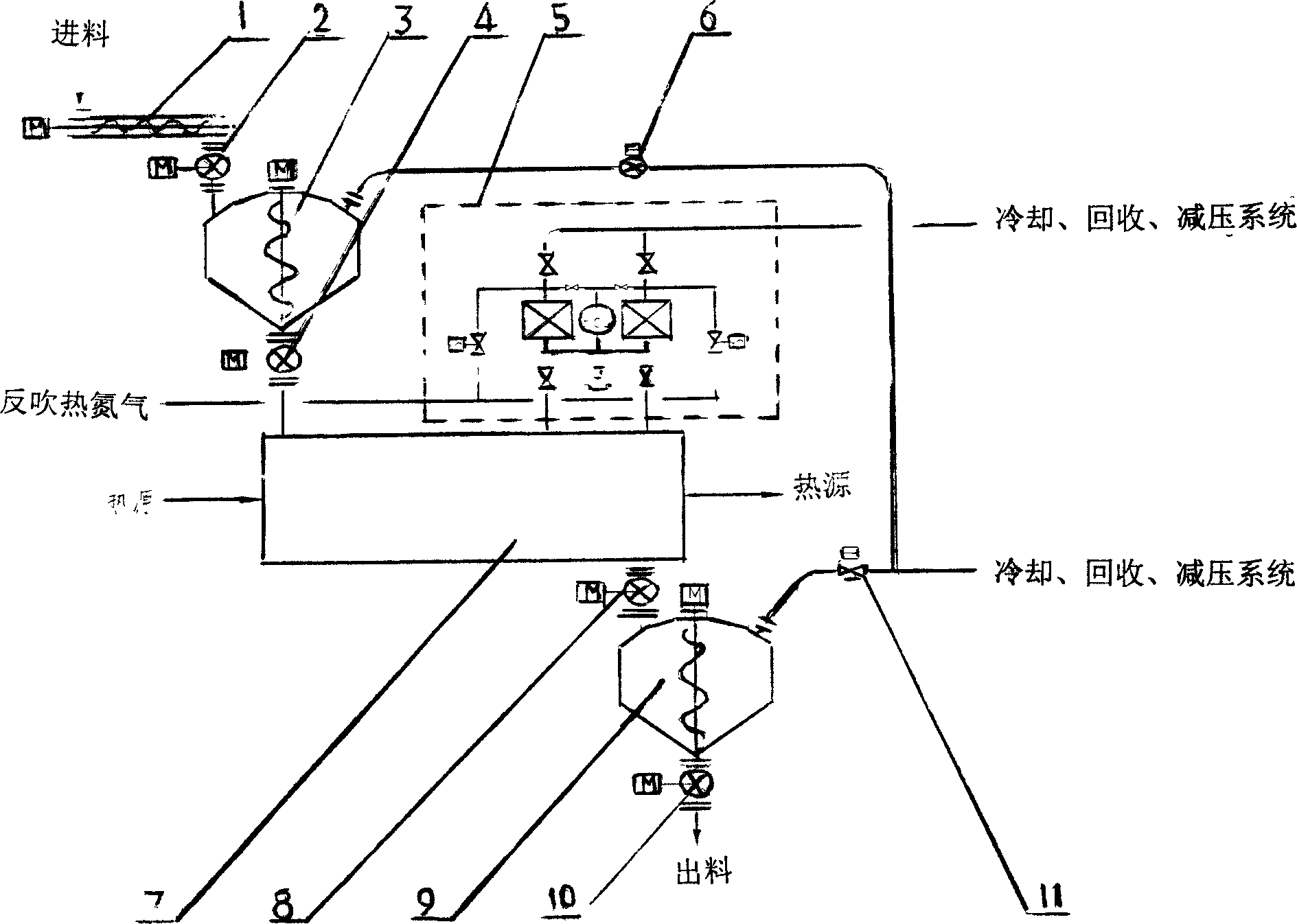

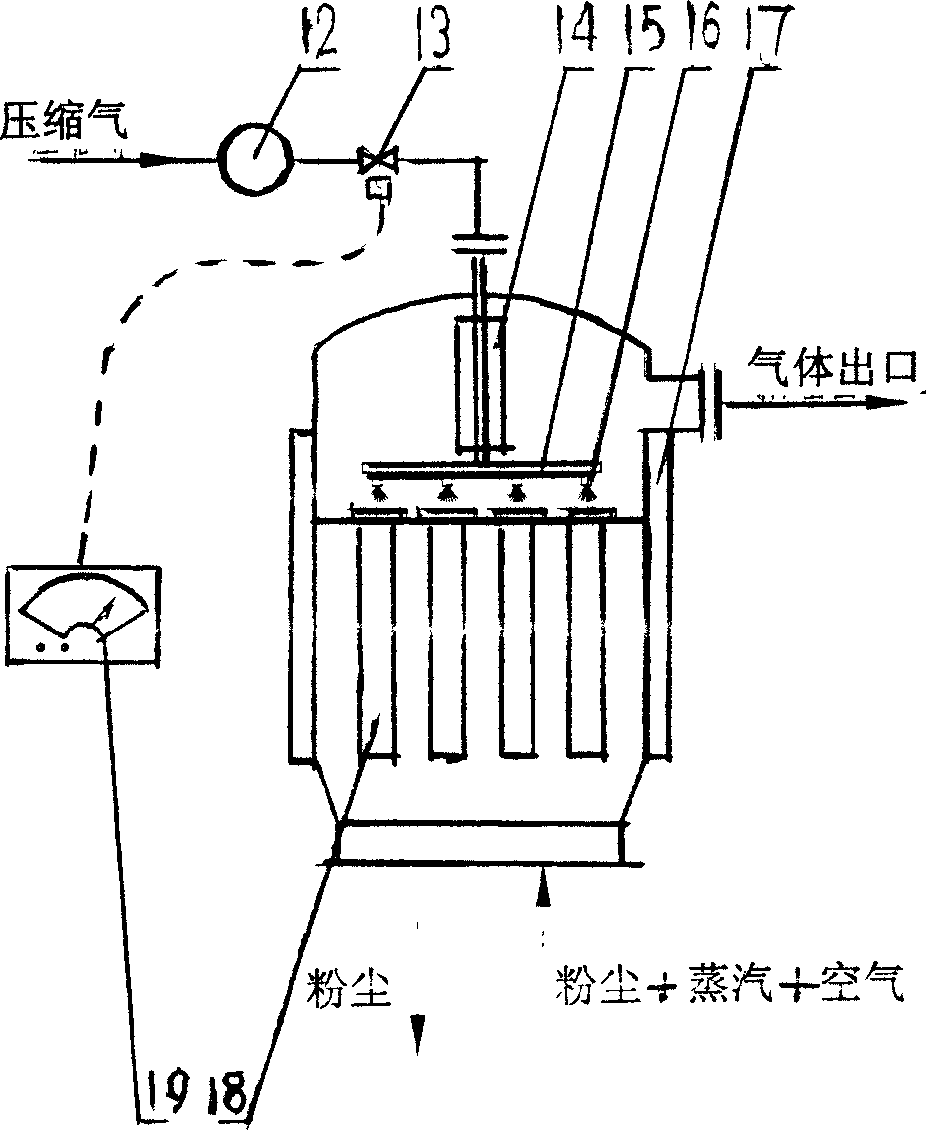

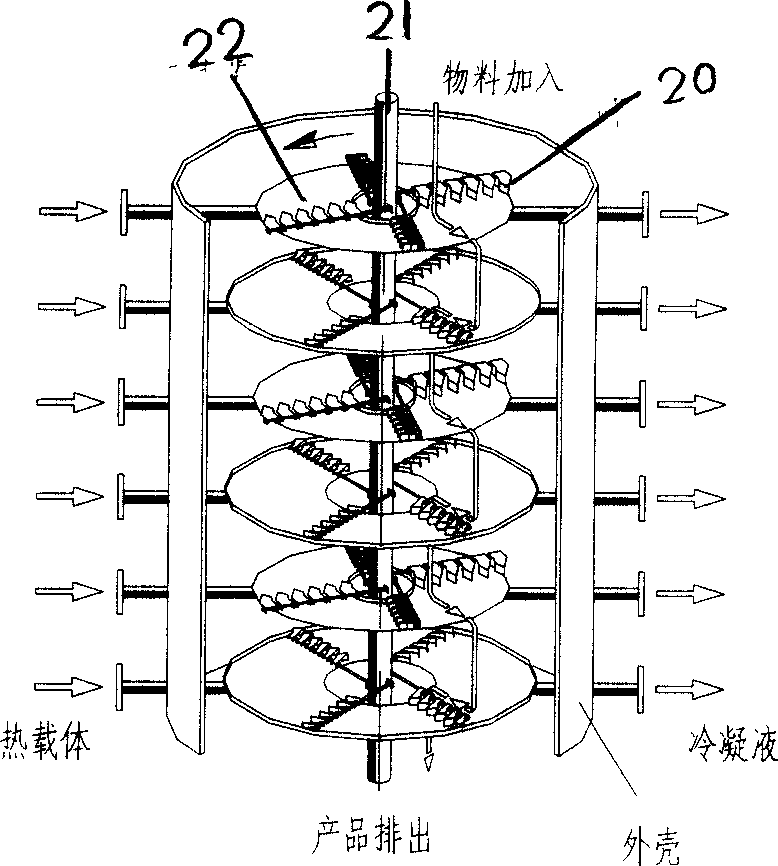

[0027] The wet material comes from the upstream section, through the screw conveyor 1 and the rotary valve 2 with high air-locking performance, continuously and evenly enters the decompression delivery tank 3, and the decompression delivery tank 3 communicates with the decompression system through the valve 6. The decompressed material enters the disc dryer (manufactured by Lanzhou Ruide Drying Technology Co., Ltd., and its products are two types of normal pressure type and vacuum type) through the rotary valve 4 with high air-locking performance. The rakes 20 are driven by the main shaft 21 to stir and turn the materials, and the materials are dried by the indirect heat transfer heat medium during the flow from top to bottom along the hollow heating plate 22 . The heat source is circulating hot water. The drying temperature was 76°C. The steam and gas mixture with solid particles in the material enter the filter 5, the gas is filtered through the filter bag 18 fixed by the c...

Embodiment 2

[0029] The drying process is the same as continuous operation, but the operating procedure is different. During intermittent operation, the screw conveyor 1 transports the material from the upstream to the rotary valve 2 with high air-locking performance, and then the material enters the decompression delivery tank 3 continuously and evenly through the rotary valve 2, and the decompression delivery tank 3 passes through the valve 6 and The decompression system is connected. The decompressed material enters the vacuum paddle dryer (manufactured by Lanzhou Ruide Drying Technology Co., Ltd., the products are: W type and T type) through the rotary valve 4 with high air-locking performance. Both the hollow heat shaft 23 and the hollow jacket 24 are fed with steam, and the wet material is heated and dried through the wall of the vessel. The drying temperature is 90°C, and at the same time, the wet material gradually moves to the discharge port under the stirring of the hollow heat ...

Embodiment 3

[0031]The drying process is the same as in Example 1. The screw conveyor 1 transports the material from the upstream to the rotary valve 2 with high air-locking performance, and then the material enters the decompression conveying tank 3 continuously and evenly through the rotary valve 2, and the decompression conveying tank 3 passes through the valve 6 and the decompression system connected. The decompressed material enters the rake dryer (manufactured by Lanzhou Ruide Drying Technology Co., Ltd., the product is a vacuum type) through the rotary valve 4 with high air-locking performance. The heating medium required for drying—the steam of low-boiling substances passes through the cylinder jacket 25 and the stirring shaft 26 to indirectly heat and dry the wet materials, and the drying temperature is 90°C. The moisture in the wet material is heated and vaporized, and the vaporized moisture is removed in time. With the continuous rotation of the stirring shaft, the wet material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com