Low temperature high-efficient energy-saving evaporation process

A high-efficiency, energy-saving and technological technology, which is applied in the direction of evaporation, general water supply saving, chemical instruments and methods, etc., can solve the problems of exhaust gas emission, low energy consumption, pollution of the atmospheric environment, etc., to improve the vacuum degree of pumping, increase the evaporation intensity, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

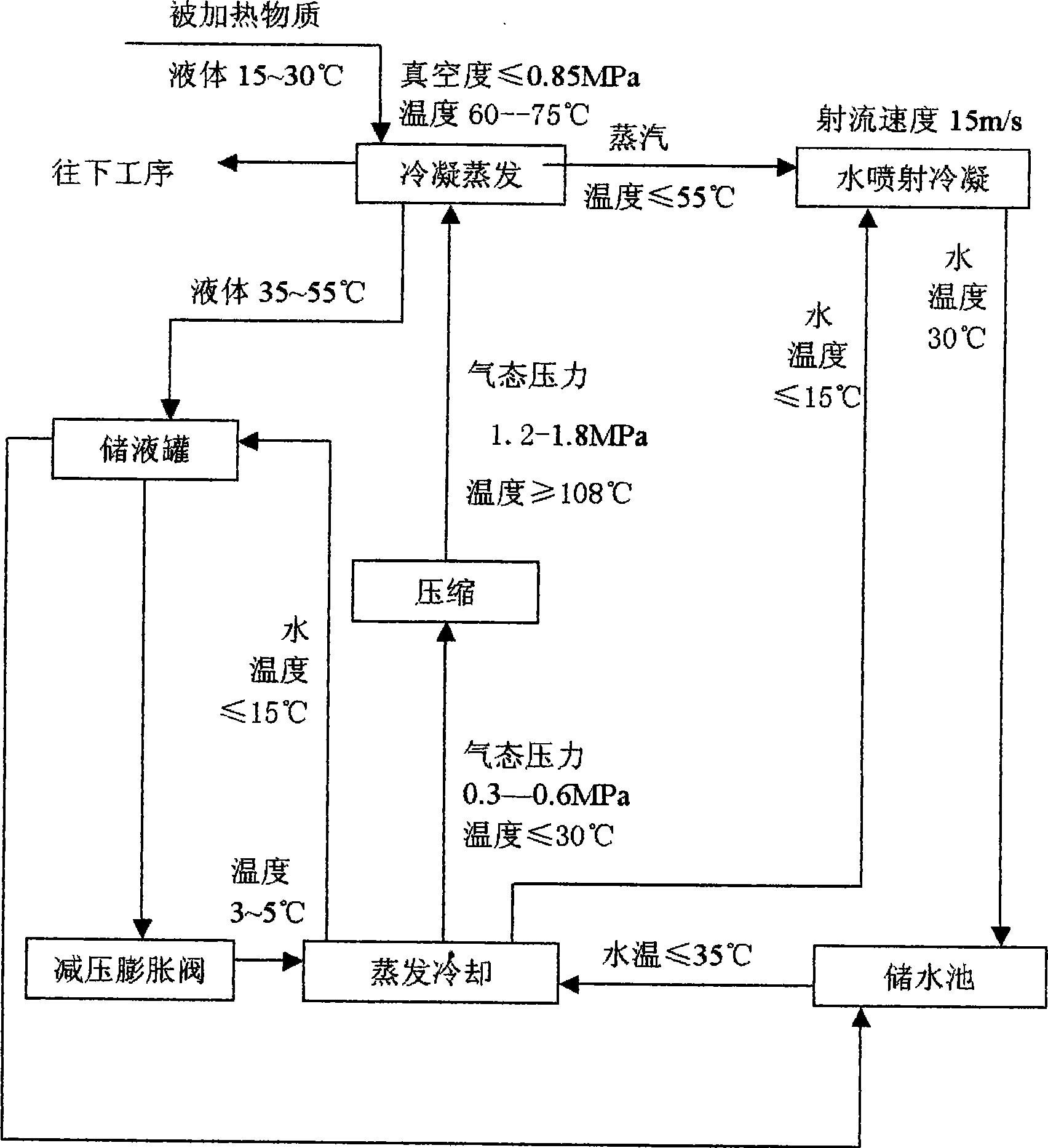

Image

Examples

Embodiment Construction

[0015] The technology of the present invention can be implemented, mainly using advanced equipment, but the equipment used in the process is the general standard equipment at home and abroad, only according to the nature of the material to be processed, the production scale, and the requirements of the process parameters, and according to the specifications and models, the process technology can be realized. advanced nature.

[0016] (1) Heat pump compression

[0017] Heat pump - compressor selection

[0018] The heat pump compresses low thermal energy into high thermal energy and is the main equipment for increasing energy. According to the nature of materials, production scale, required heating and cooling capacity and working pressure ≤ 3MPa, it is generally better to choose a slide compressor.

[0019] Using R22 refrigerant as the carrier, the sliding compressor is driven by the motor, and the R22 refrigerant gas with a suction temperature of ≤30°C and a pressure of 0.3-0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com