Para toluene sulfonate continuous drying method

A technology of p-toluenesulfonamide and drying method, which is used in progressive dryers, drying solid materials, and drying solid materials without heating, etc., can solve the problems of low drying rate and efficiency, unstable product quality, and high operating intensity. , to achieve the effect of fast drying speed, stable product quality and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

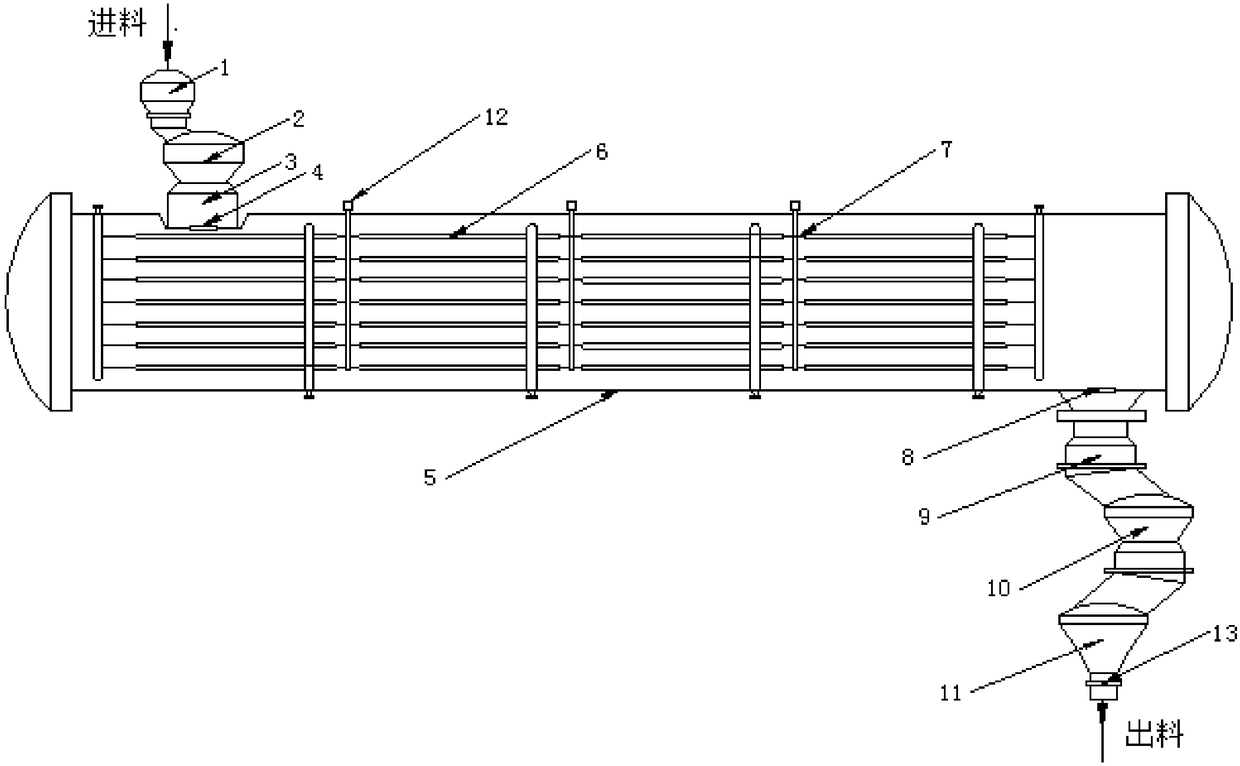

[0041] The feed buffer chamber breaks the vacuum and reaches normal pressure. After the reaction, the p-toluenesulfonamide material containing 10% water and alcohol enters the feed buffer chamber, and the feed buffer chamber is evacuated to a vacuum of 0.098MPa. The valve between the warehouse and the feed buffer tank, the pressure is balanced, the material enters the feed buffer tank, the valve of the feed buffer tank and the feed control warehouse is opened, the material enters the feed control warehouse, and then the material passes through the feed rotary valve Reach the track.

[0042]After the material reaches the track in the barrel, it passes through the 1st, 2nd, 3rd, 4th, 5th, 6th, and 7th track respectively, and passes through the 1st temperature section 70 from top to bottom. ~80℃, the 2nd and 3rd temperature section is 60~70℃, the 4th and 5th temperature section is 50~60℃, the 6th and 7th temperature section is 40~50℃, and the 7th last heating plate cools down Se...

Embodiment 2

[0046] The feed buffer chamber breaks the vacuum and reaches normal pressure. After the reaction, the p-toluenesulfonamide material containing 10% water and alcohol enters the feed buffer chamber, and the feed buffer chamber is evacuated to a vacuum of 0.098MPa. The valve between the warehouse and the feed buffer tank, the pressure is balanced, the material enters the feed buffer tank, the valve of the feed buffer tank and the feed control warehouse is opened, the material enters the feed control warehouse, and then the material passes through the feed rotary valve Reach the track.

[0047] After the material reaches the track in the barrel, it passes through the 1st, 2nd, 3rd, 4th, 5th, 6th, and 7th track respectively, and passes through the first temperature section 80 from top to bottom. ~85℃, the 2nd and 3rd temperature range is 75~80℃, the 4th and 5th temperature range is 65~75℃, the 6th and 7th temperature range is 45~65℃, the last heating plate in the 7th cooling down ...

Embodiment 3

[0051] The feed buffer chamber breaks the vacuum and reaches normal pressure. After the reaction, the p-toluenesulfonamide material containing 10% water and alcohol enters the feed buffer chamber, and the feed buffer chamber is evacuated to a vacuum of 0.098MPa. The valve between the warehouse and the feed buffer tank, the pressure is balanced, the material enters the feed buffer tank, the valve of the feed buffer tank and the feed control warehouse is opened, the material enters the feed control warehouse, and then the material passes through the feed rotary valve Reach the track.

[0052] After the material reaches the track in the barrel, it passes through the 1st, 2nd, 3rd, 4th, 5th, 6th, and 7th track respectively, and passes through the first temperature section 80 from top to bottom. ~89℃, the 2nd and 3rd temperature range is 70~80℃, the 4th and 5th temperature range is 60~70℃, the 6th and 7th temperature range is 45~60℃, the last heating plate in the 7th cooling down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com