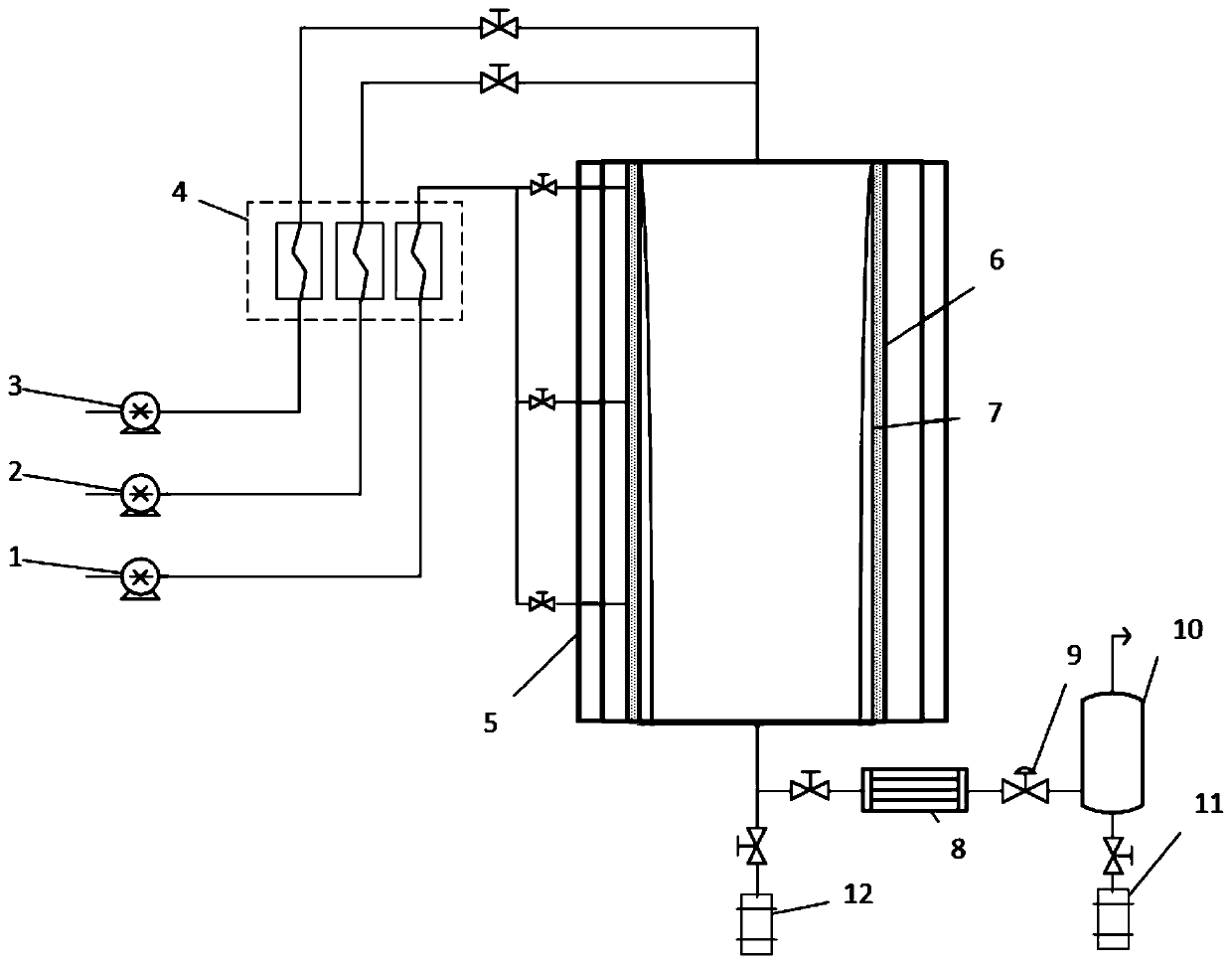

A system and method for adjusting water film coverage of supercritical water oxidation evaporation wall reactor

A supercritical water oxidation and evaporation wall technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of discontinuous water film, strong convective diffusion and mixing, Solve the problems of low water film coverage in the supercritical area, and achieve the effect of optimizing the formation of water film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The present invention is a method for regulating the water film coverage of supercritical water oxidation and evaporation wall reactor, comprising:

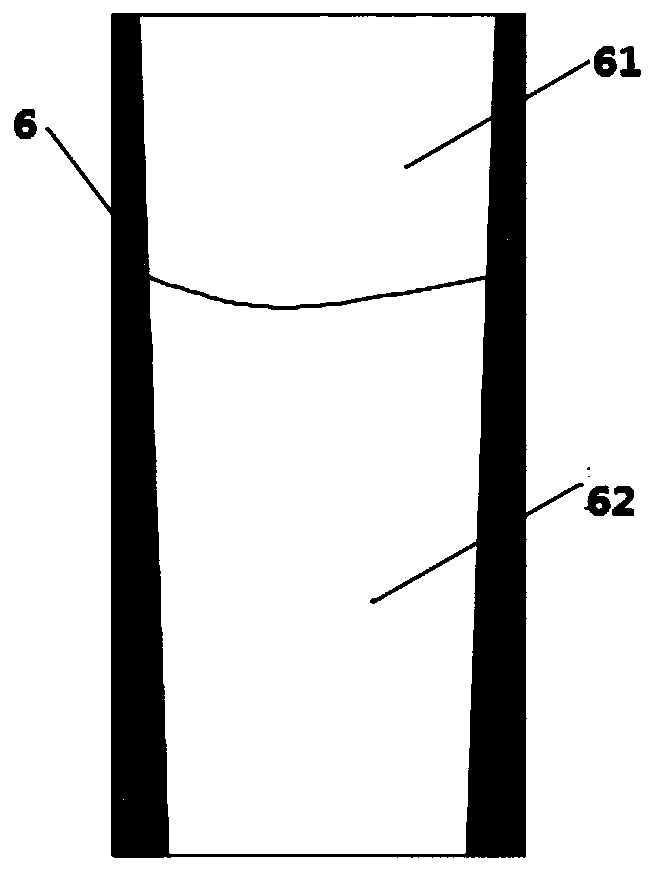

[0049] Set the evaporation intensity of the evaporating wall reactor to 0.33, the inlet temperature of the evaporating wall water is 570K, and the preheating temperature of the organic material is 730K; The flow rate is 1.05L / h; at this time, the water film coverage in the reactor can reach the optimal value, and the water film coverage can reach more than 85% in the upper supercritical reaction zone, and more than 95% in the lower subcritical zone. Water film coverage.

[0050] The coverage of the water film can be adjusted by adjusting the evaporation intensity of the evaporated water; ensure that other parameters are at a certain reasonable value. When the evaporation intensity is in the range of 0.15-0.35, the supercritical water oxidation effect is better, and the evaporation can be increased within this range. Inten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com