Shell and tube graphite falling film evaporation heater

A falling-film evaporation and heater technology is applied in the field of graphite falling-film evaporation heaters, which can solve the problems that graphite heat exchange tubes have great influence, surface crystallization or scaling is difficult to handle, and cannot be used for falling-film evaporation heaters, etc. Achieve the effect of improving equipment reliability, reducing power consumption and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

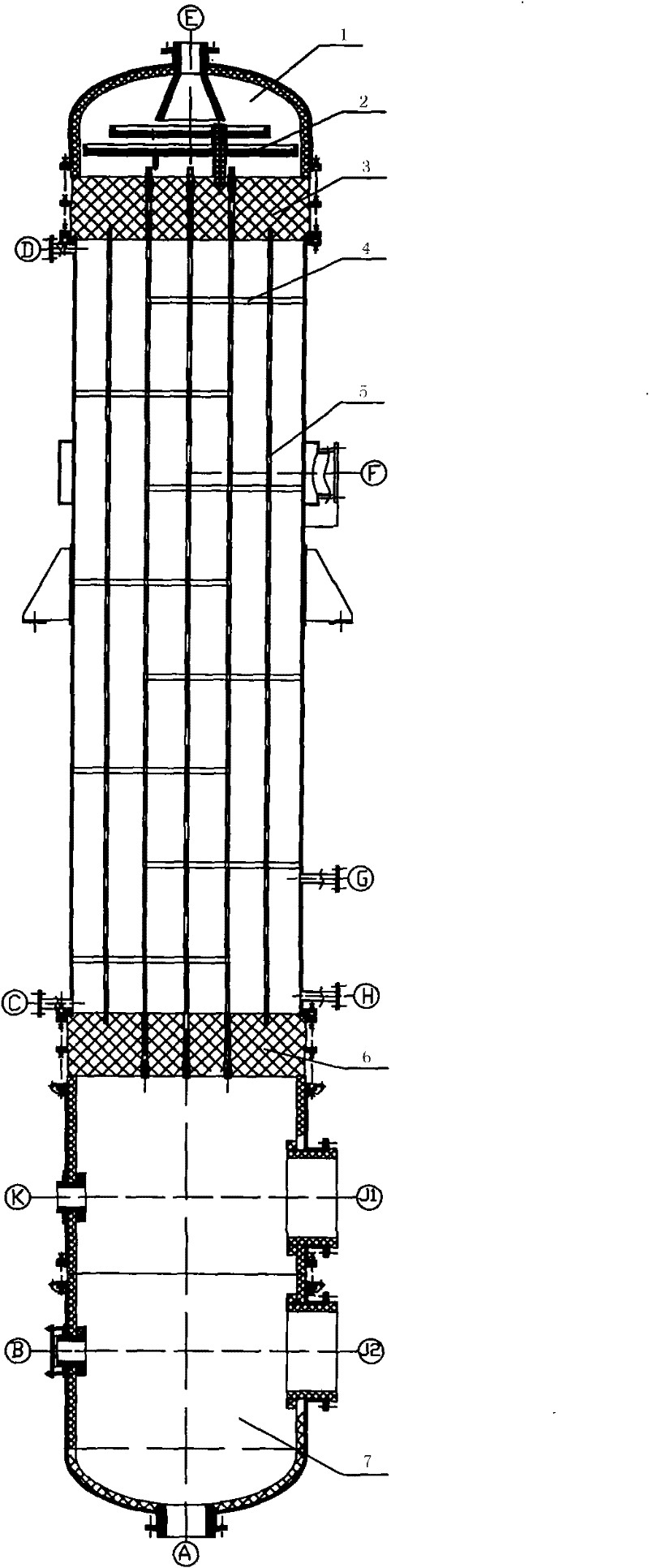

[0017] The accompanying drawing discloses a non-restrictive structural schematic diagram of a preferred embodiment involved in the present invention, and the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

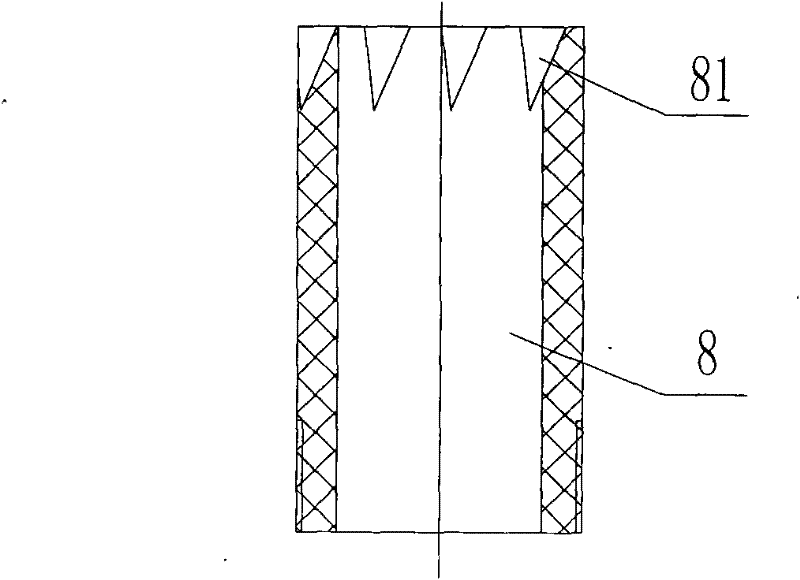

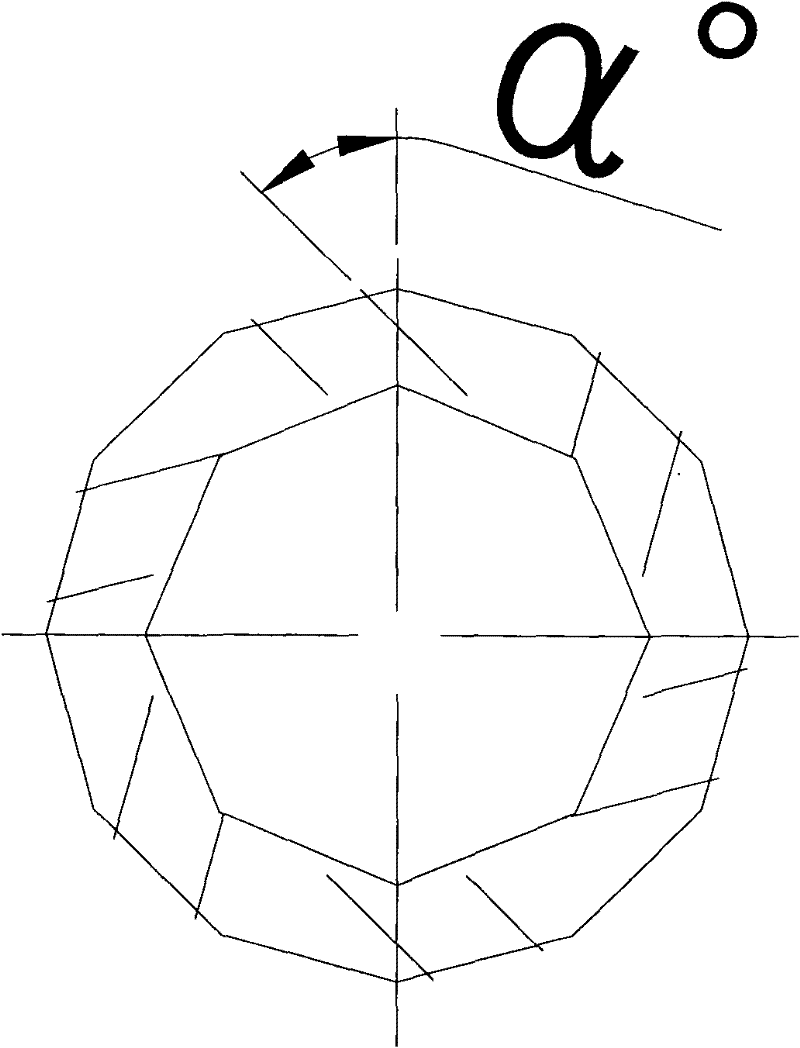

[0018] Such as figure 1 As shown, the tube-and-tube graphite falling film evaporation heater of the present invention includes an upper tube box 1, a graphite liquid distribution device, an upper seal 3, a graphite heat exchange assembly, a lower seal 6 and a lower tube box 7. The upper tube box 1, the upper seal 3, the graphite heat exchange assembly, the lower seal 6 and the lower tube box 7 are stacked sequentially from top to bottom, and the graphite heat exchange assembly includes more than two graphite heat exchange tubes 5, A sealing assembly and a tube sheet 4, the sealing assembly is sealed between the graphite heat exchange tube 5 and the tube sheet 4, the sealing assembly includes a sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com