Phosphoric acid evaporation process and device thereof

A process, phosphoric acid technology, applied in phosphorus compounds, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of large investment, high operating cost and high maintenance cost of phosphoric acid concentration plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

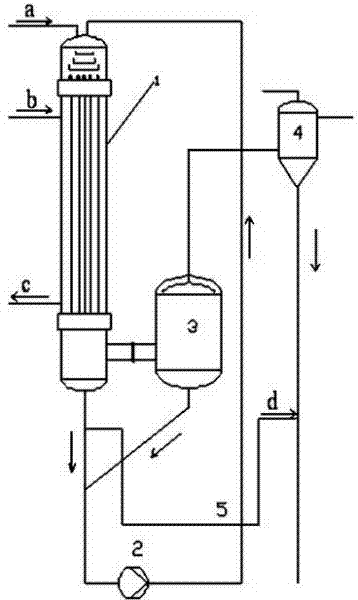

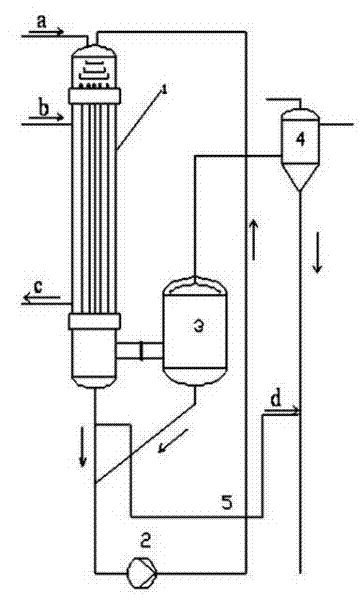

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

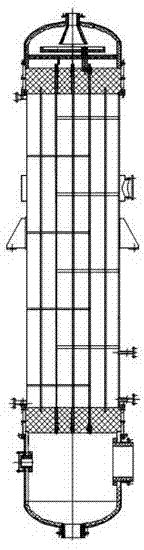

[0013] as attached figure 1 As shown, (1) Material introduction Dilute phosphoric acid enters through the top of the heater, and there are three-layer disc distributors inside, so that dilute phosphoric acid can be evenly distributed to the entrance of each heat exchange tube, ensuring that dilute phosphoric acid can flow along the inside of the heat exchange tube. The wall flows downward evenly in the form of a film; (2) The dilute phosphoric acid dehydration steam enters the heater from the side wall of the heater, and the steam enters the heater shell to heat the outer wall of the heat exchange tube, and the heat is transferred to the inside of the tube through the tube wall. The dilute phosphoric acid is heated during the flow process, and the water in it is evaporated; (3) the condensed water is collected from the steam, and the condensed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com