Production method of lumpy brown sugar with donkey-hide gelatin

A technology of donkey-hide gelatin brown sugar and its production method, which is applied in sugar production, sucrose production, sugar products, etc., can solve the problems of complex process and high equipment investment, and achieve the effects of simple process, low investment cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

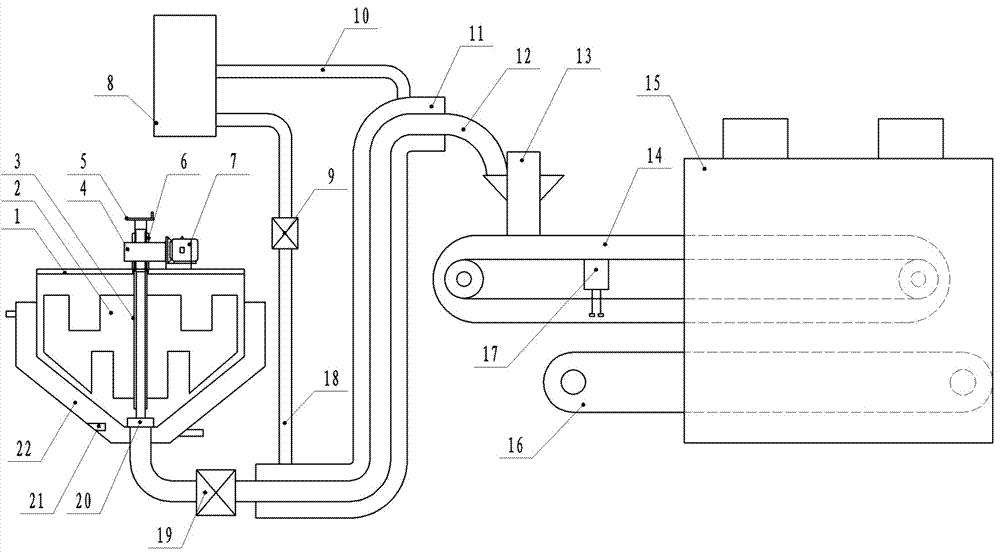

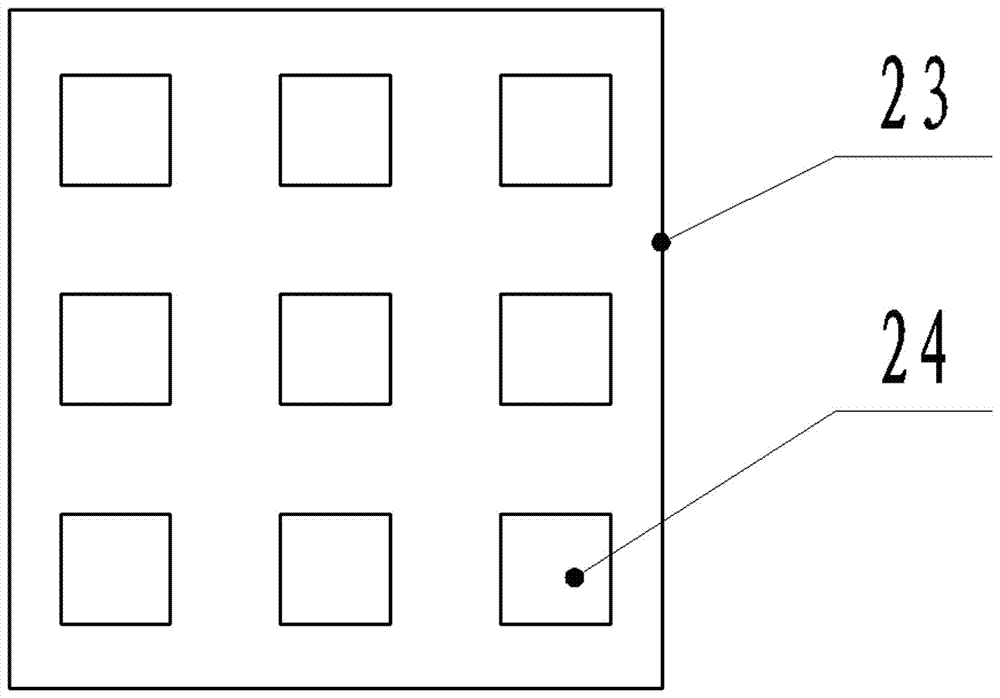

Method used

Image

Examples

Embodiment 1

[0043] The donkey-hide gelatin brown sugar block can be prepared by adopting the following production process steps:

[0044] (1) Put the precipitated and filtered fresh sugarcane juice and brown sugar powder into the brown sugar cooking container of the brown sugar block refining and boiling molding device and heat it with heat transfer oil. The weight ratio of fresh sugarcane juice and brown sugar powder is 1:4.5-5.5; heat conduction The temperature of the oil is 120-150°C; fresh sugarcane juice refers to sugarcane juice that has been squeezed from sugarcane for no more than 24 hours;

[0045] (2) Constantly stir the raw materials in the brown sugar cooking container. After 40-50 minutes, the fresh sugarcane juice and brown sugar powder are dissolved and mixed to form a syrup. When the water content of the syrup is 8-12%, stop heating;

[0046] (3) After stopping heating, add donkey-hide gelatin powder of 1% by weight of the syrup, 2% of jujube powder and 1% wolfberry powder...

Embodiment 2

[0056] The donkey-hide gelatin brown sugar block can be prepared by adopting the following production process steps:

[0057] (1) Put the fresh sugarcane juice and brown sugar powder purchased from the sugar factory into the brown sugar cooking container of the brown sugar block refining and cooking device and heat it with heat transfer oil. The weight ratio of fresh sugarcane juice and brown sugar powder is 1:4.5-5.5 ;The temperature of the heat conduction oil is 120-150°C; Fresh sugarcane juice refers to the sugarcane juice squeezed from sugarcane for no more than 24 hours;

[0058] (2) Constantly stir the raw materials in the brown sugar cooking container. After 40-50 minutes, the fresh sugarcane juice and brown sugar powder are dissolved and mixed to form a syrup. When the water content of the syrup is 8-12%, stop heating;

[0059] (3) After stopping heating, add donkey-hide gelatin powder, 2.5% red date powder and 2.5% wolfberry powder by weight of the syrup into the syru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com