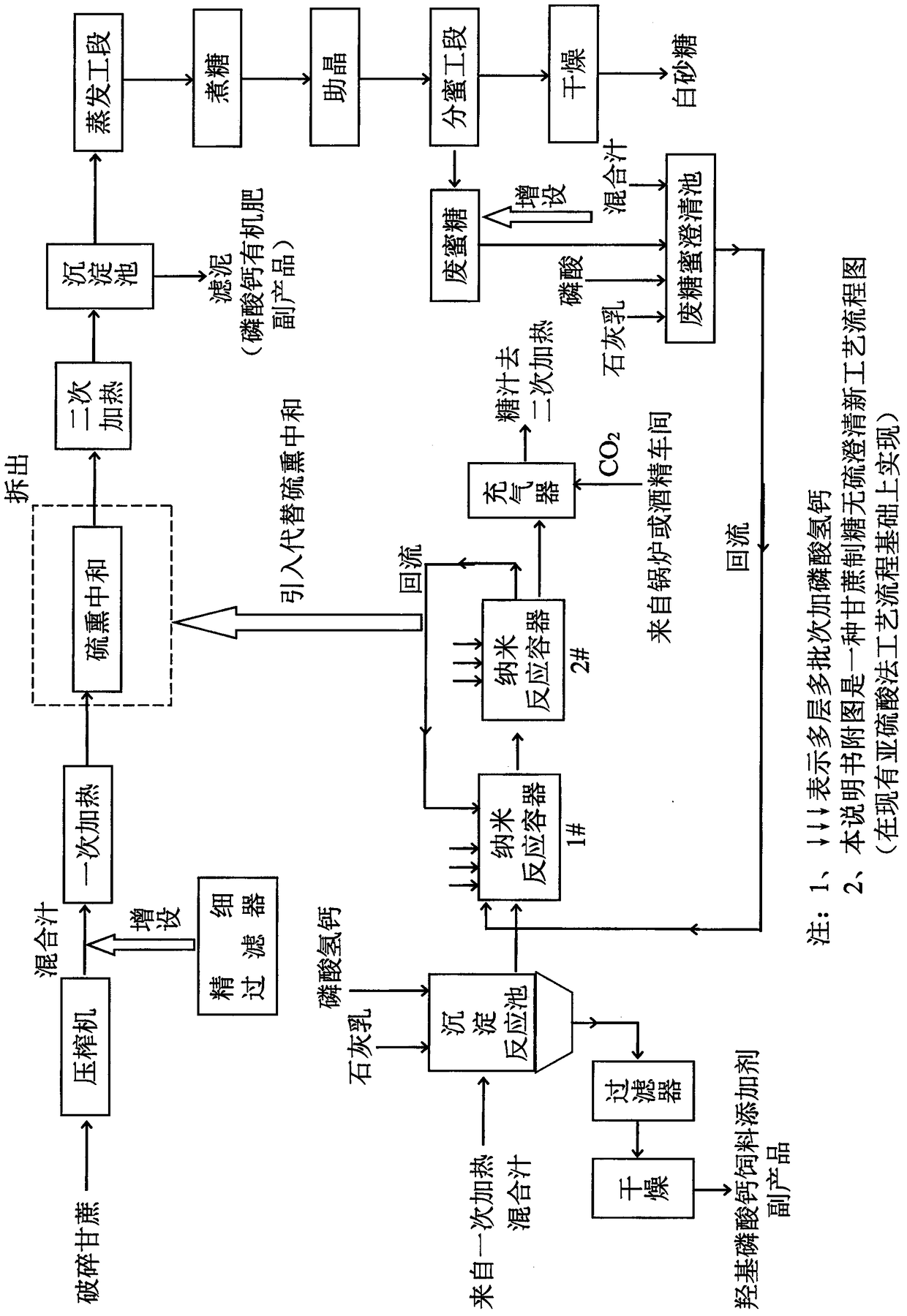

Novel cane sugar manufacturing sulfur-free clarification process

A new process, sugarcane technology, applied in the production of sucrose, juice extraction from sugarcane, sugar drying, etc., can solve the problems of affecting the safety of sugar, not finding a process method, etc., achieving less capital investment in equipment, improving product quality, and improving The effect of sugar yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1 The squeezed mixed juice was taken from 900 ml of a sugar company in Yuxi City, Yunnan Province, which processed 3,000 tons of sugarcane per day. It was first filtered with a self-made fine filter, the pre-ash pH value was 7.0, and the primary heating temperature was 45°C. In a 1000ml beaker, use 5 grams of milk of lime and calcium hydrogen phosphate to adjust the pH value to 10.5. After 15 minutes, there is a precipitate, which is filtered to obtain a filter residue, which is 7.2 grams after drying. This product is a calcium hydroxyphosphate feed additive containing nutritional compounds such as amino acids. The filtrate precipitated juice enters two self-made interconnected nano-reaction vessels, adjusts the pH value of the sugar juice to 11.0 with a small amount of lime milk, adds 10 grams of calcium hydrogen phosphate in a multi-level and multi-batch manner, and in the second nano-reaction vessel The middle part takes out a small amount of sugar juice and ...

Embodiment 2

[0013] Embodiment 2 samples 900 milliliters with the same company as implementation 1, and the implementation process is the same, only changing the following process parameters. The pH value of the mixed juice pre-ash is 7.2, the primary heating temperature is 40°C, and the sugar juice is filled with carbon dioxide to reduce the pH value to 7.2. Finally, clear and transparent clear juice with light color is obtained. Obtained through laboratory analysis: Gravity purity GP (%) 86.02, color value 1320IU, turbidity 300MAU, pH value 7.2 compare with embodiment 1 this company's sulfite process data, the quality of this new process of clarification without sulfur exceeds this The quality of the company.

Embodiment 3

[0014] Embodiment 3 The squeezed mixed juice is taken from 900 milliliters of a certain sugar factory in Honghe Prefecture, Yunnan Province, which processes 1400 tons of sugarcane per day. The sampling and implementation process are the same as in Example 1. The technological parameter that it changes is to squeeze 900 milliliters of mixed juice, and sampling, implementation process are identical with embodiment 1. The changed process parameters are that the pre-ash pH value of the squeezed mixed juice is 7.1, the primary heating temperature is 43°C, and the carbon dioxide charging of the sugar juice is reduced to 7.2. The end result is a clear, transparent juice with some color. Laboratory analysis shows: gravity purity GP (%) 85.69, color value 1560IU, turbidity 358MAU, pH value 7.1. The clear juice of this plant has a gravity purity of GP (%) 84.23, a color value of 2500IU, a turbidity of 462MAU, and a pH value of 7.0. It can be seen that the quality of the clear juice of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com