Pipeline vibration-absorption clamping hoop with adjustable direction

A technology of clamps and pipelines, which is applied in the direction of pipe components, pipe brackets, pipes/pipe joints/pipe fittings, etc., can solve problems such as reduction, and achieve the effects of strong environmental adaptability, precise and adjustable vibration absorption frequency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

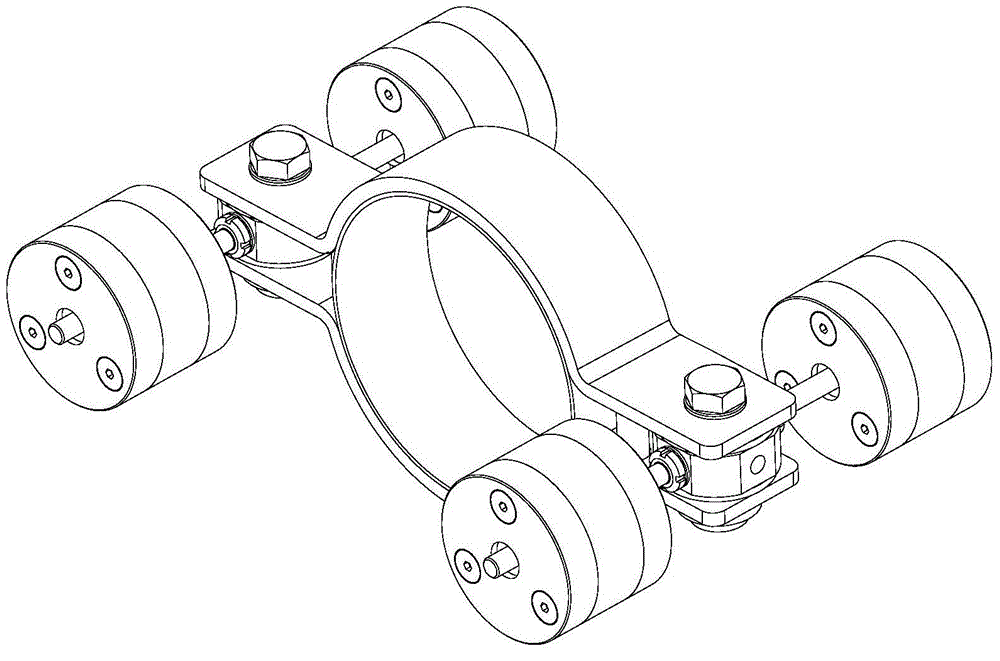

[0045] The invention provides a pipeline vibration-absorbing clamp with adjustable direction, see the attached figure 1 , including: clamp assembly and vibration-absorbing assembly;

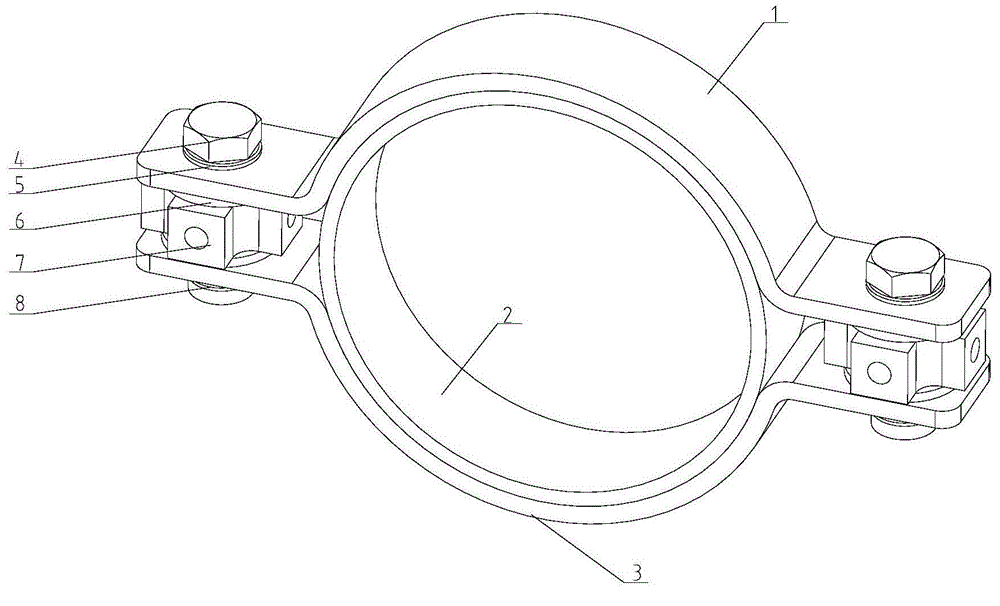

[0046] See attached figure 2 , the clamp assembly includes: an upper clamp ring 1, a rubber pad 2, a lower clamp ring 3, a mounting bolt 4, a washer 5, an adjustment block 6, an adapter block 7 and a nut 8;

[0047] The upper clamp ring 1 and the lower clamp ring 3 are both semi-circular rings, and connecting plates are provided at both ends of the semi-circular rings;

[0048] The rubber pad 2 is a ring;

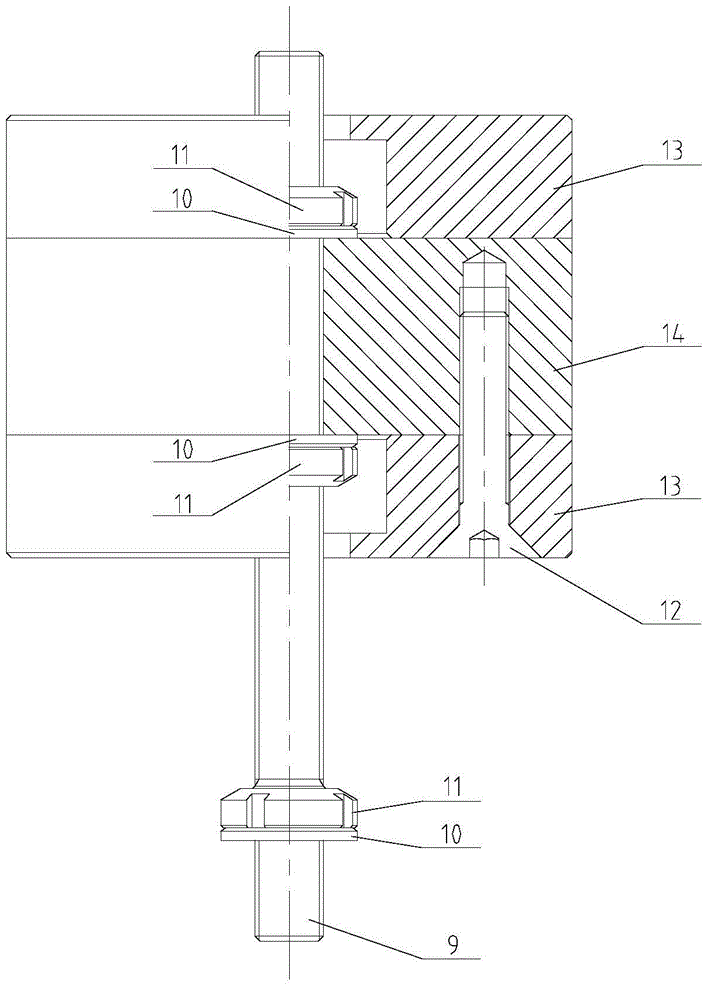

[0049] See attached Figure 4 , 5 , the adapter block 7 is provided with a central through hole and a threaded hole perpendicular to the central through hole, the number of the threaded holes is two or more;

[0050] The upper clamp ring 1 and the lower clamp ring 3 are docked to form an arc surface structure and are set on the outer circumferential surface of the rubber pad 2; two adapt...

Embodiment 2

[0065] See attached Image 6 , On the basis of Embodiment 1, the connecting plates at both ends of the upper clamp ring 1 and the lower clamp ring 3 of the clamp assembly are fixed on the bracket.

Embodiment 3

[0067] On the basis of Embodiment 1 or 2, the vibration-absorbing component can be designed to have two frequencies, so that the pipeline vibration-absorbing clamp can simultaneously reduce two line spectra.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com