Vibrating-type anti-blocking printer spray head assembly

A nozzle assembly and printer technology, applied in the field of 3D printing, can solve the problems of nozzle clogging, unavoidable nozzle clogging, limited anti-slip effect of the material guide tube, etc., and achieve the effect of reasonable structure, good thermal conductivity, and overcoming instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

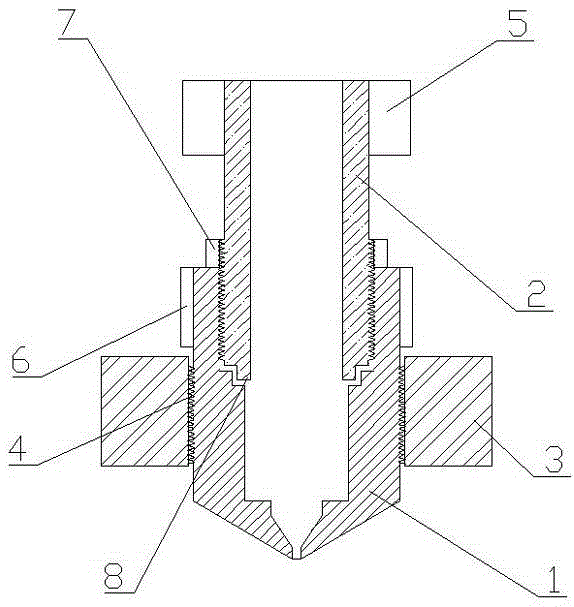

[0025] see figure 1 , the nozzle assembly of the vibration-type anti-blocking printer of the present invention includes a nozzle 1, a feed throat 2, a heater 3, and a screw mechanism 4; the feed port of the nozzle 1 communicates with the discharge port of the feed throat 2 , the heater 3 is arranged on the outside of the nozzle and closely contacts the heated area of the nozzle; the nozzle, the feed throat and the heater are all fixedly connected by a threaded mechanism 4; the transition between the nozzle and the feed throat is provided with a leak-proof Step 8, the screw mechanism fixedly connecting the nozzle 1 and the feed throat 2 is set on the inner wall of the upper cavity of the nozzle, and the outer wall of the feed throat is correspondingly provided with a reverse thread mechanism, and the thread of the screw mechanism extends beyond the feed inlet of the nozzle ; It also includes a vibrator 5 arranged on the outer wall of the feed throat 2 to force the silk materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com