Piezoelectric energy collecting system

A kind of energy harvesting and piezoelectric technology, applied in electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., can solve the problem that the vibration frequency of piezoelectric vibrators cannot be adjusted, and achieve Adjustable vibration frequency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

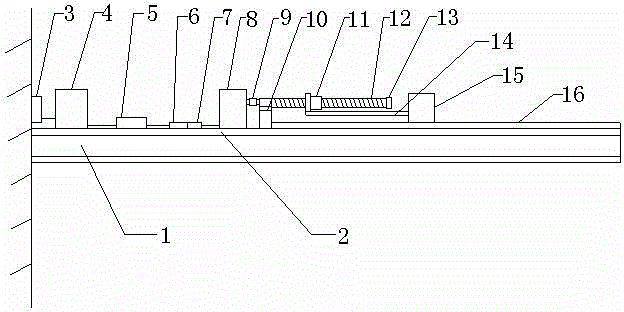

[0014] The piezoelectric energy harvesting system includes a piezoelectric cantilever beam 1, a piezoelectric sheet 2, a first vibration frequency sensor 3, a micro capacitor 4, a second vibration frequency sensor 5, a single chip microcomputer 6, a motor drive chip 7, a micro motor 8, a connected Shaft 9, support frame 10, ball nut 11, ball screw 12, nut 13, connecting rod 14, mass block 15 and slideway 16; the piezoelectric cantilever beam 1 is installed on the vibrating structure, and the piezoelectric sheet 2 Covering the front and back sides of the piezoelectric cantilever beam 1, the first vibration frequency sensor 3 is installed on the vibration structure, the first vibration frequency sensor 3 is connected to the micro capacitor 4 and the single chip microcomputer 6 respectively through wires, the micro capacitor 4, the second Vibration frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com