Handheld type branch vibration and fruit harvesting device

A fruit harvesting and hand-held technology, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of arm vibration fatigue damage, easy-to-fall-off branches impact, easy-to-damage branches, etc., to avoid vibration fatigue damage, Effect of improving harvesting efficiency and reducing harvesting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

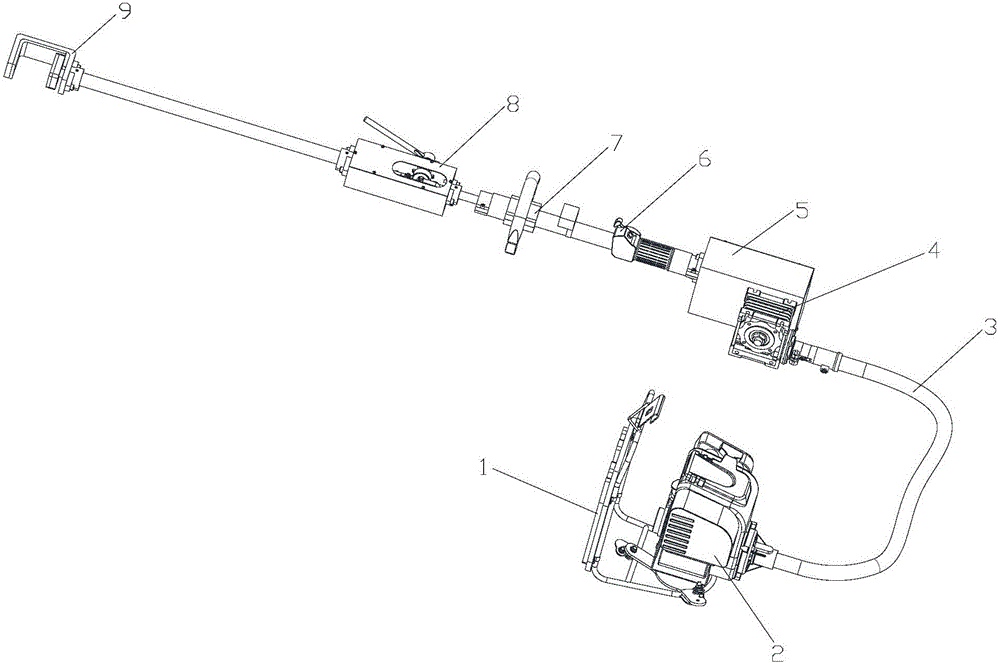

[0045] A hand-held tree branch vibrating fruit harvesting device, its structure is as follows figure 1 As shown, it includes an engine carrier, a gasoline engine, a transmission mechanism, a vibration mechanism, a manual clamping mechanism, a tree branch chuck, a ratchet locking mechanism, a vibration-damping handheld mechanism, and a control system.

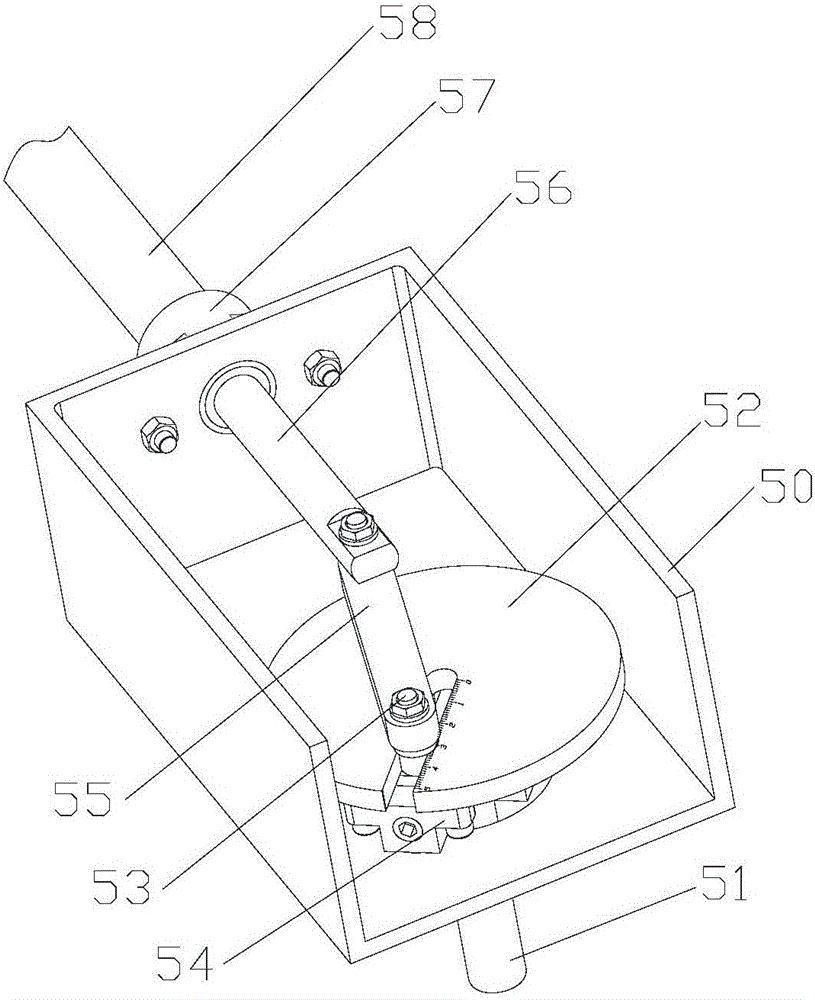

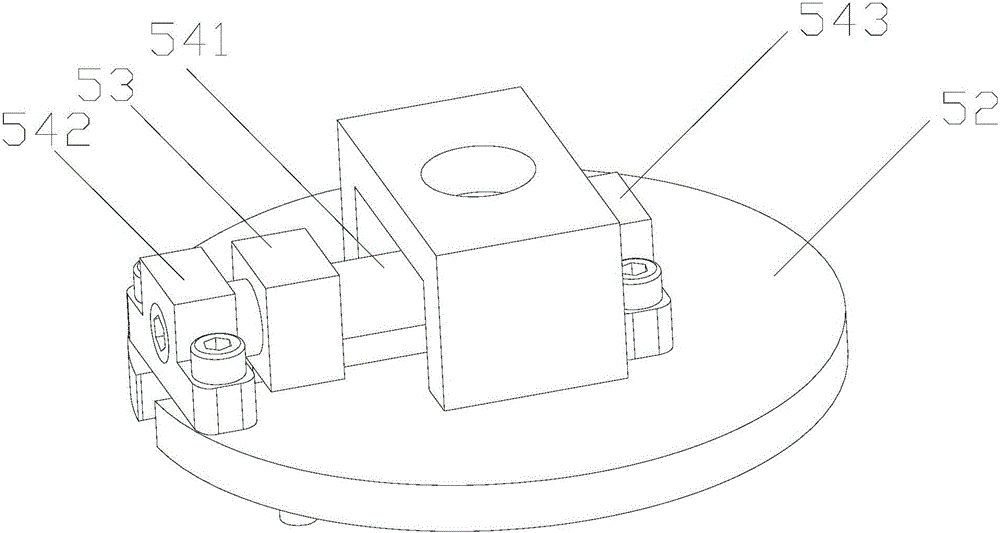

[0046] The gasoline engine is mounted on the engine carrier. The output shaft of the gasoline engine is connected to the flexible shaft of the transmission mechanism, the other end of the flexible shaft is connected to the input shaft of the worm gear reducer, the output shaft of the reducer is connected to the eccentric wheel of the vibration mechanism, and the vibration rod of the vibration mechanism is connected to the manual clamping mechanism connected, the manual clamping mechanism con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com