Horizontal unidirectional vibration table with adjustable amplitude and frequency

A vibrating table, horizontal technology, applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve the problems of low driving efficiency, complex equipment, and complex force-transmitting mechanical devices, avoid strong natural vibration, improve Performance indicators, the effect of easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be briefly described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other implementations obtained by those skilled in the art without creative work Examples, all belong to the protection scope of the present invention.

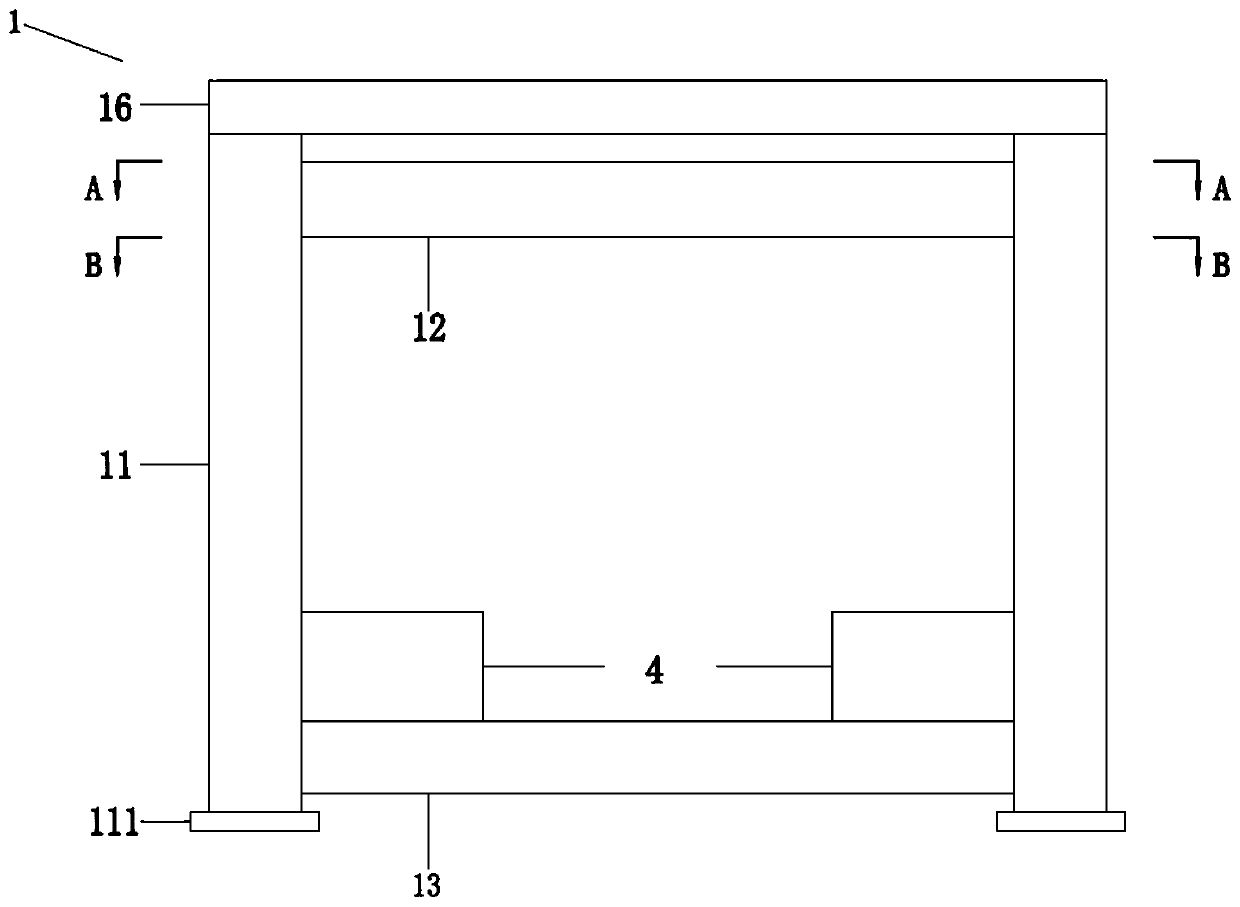

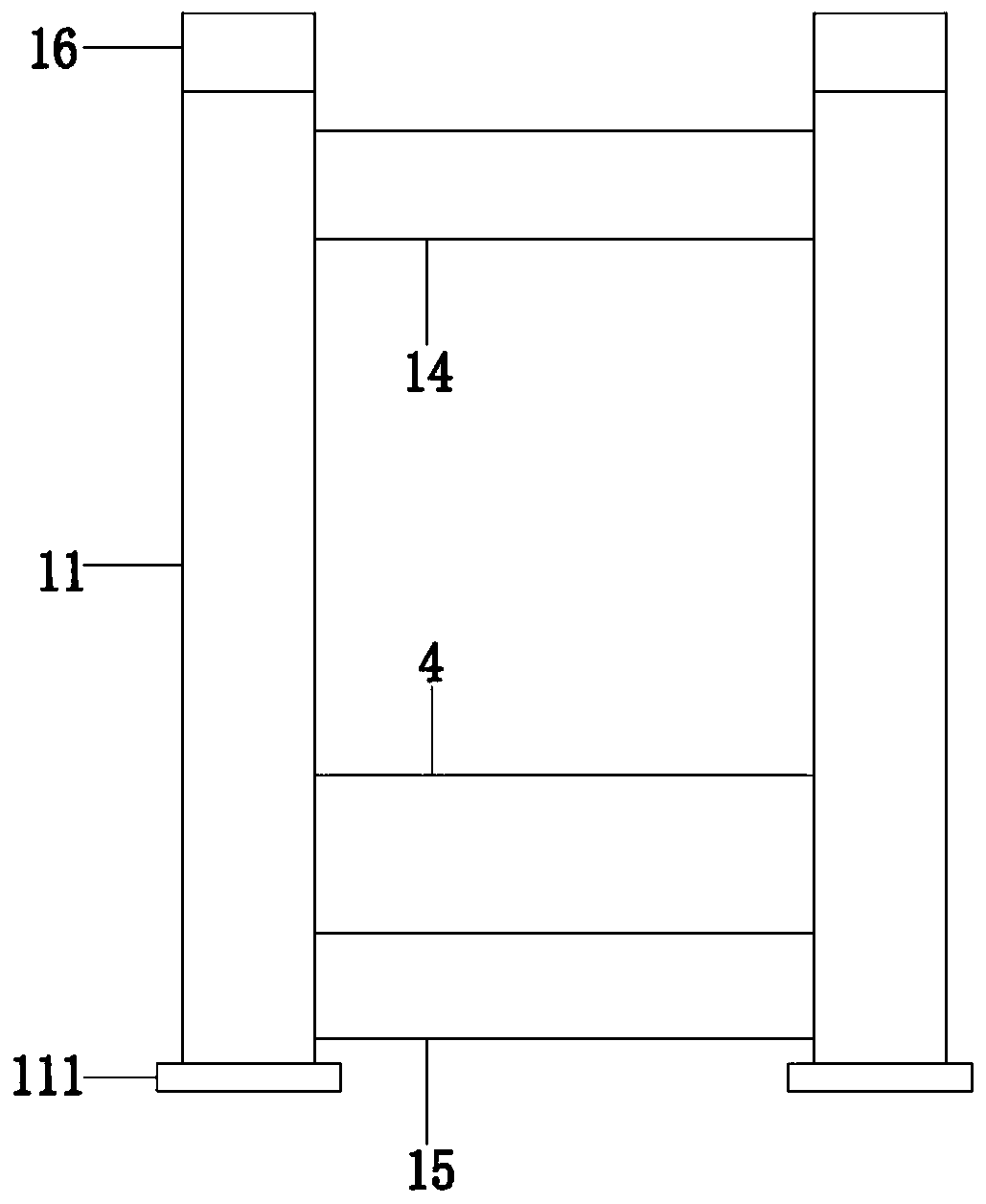

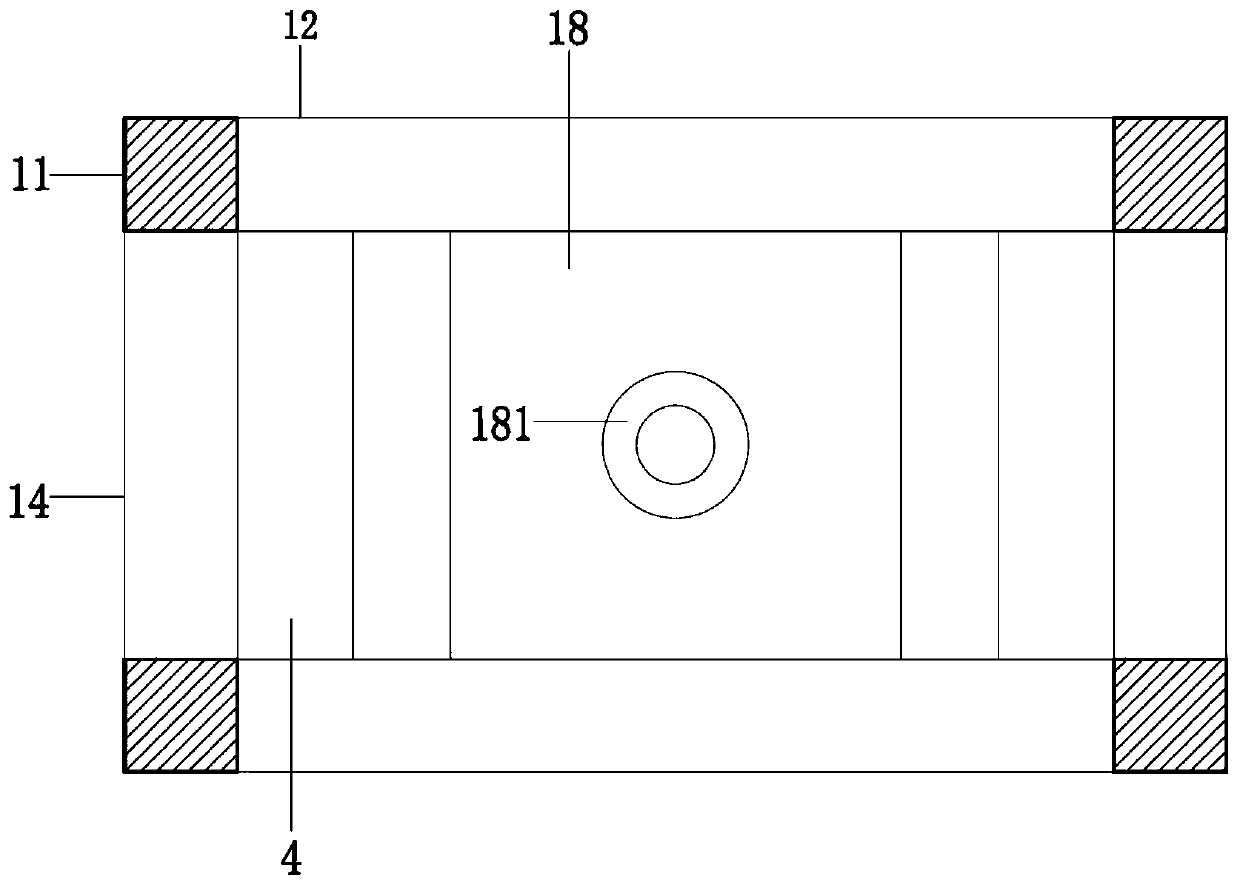

[0037] Figure 1-Figure 9 Shows a preferred embodiment of the present invention, and analyzes its structure in detail from different angles

[0038] A horizontal one-way vibrating table with adjustable amplitude and frequency includes a bracket, a vibrating table surface and a driving mechanism.

[0039] Such as figure 1 , 2 As shown, the bracket 1 is made of a hard metal material, and comprises four columns 11, two upper beams 12, two lower beams 13, two upper longitudinal beams 14 and two lower longitudinal beams 15. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com