Material surface ultrasonic impact strengthening device and method

An ultrasonic impact and strengthening device technology, applied in the field of material surface ultrasonic impact strengthening device, can solve problems such as surface roughness increase, and achieve the effects of reducing porosity, improving material life, and facilitating installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

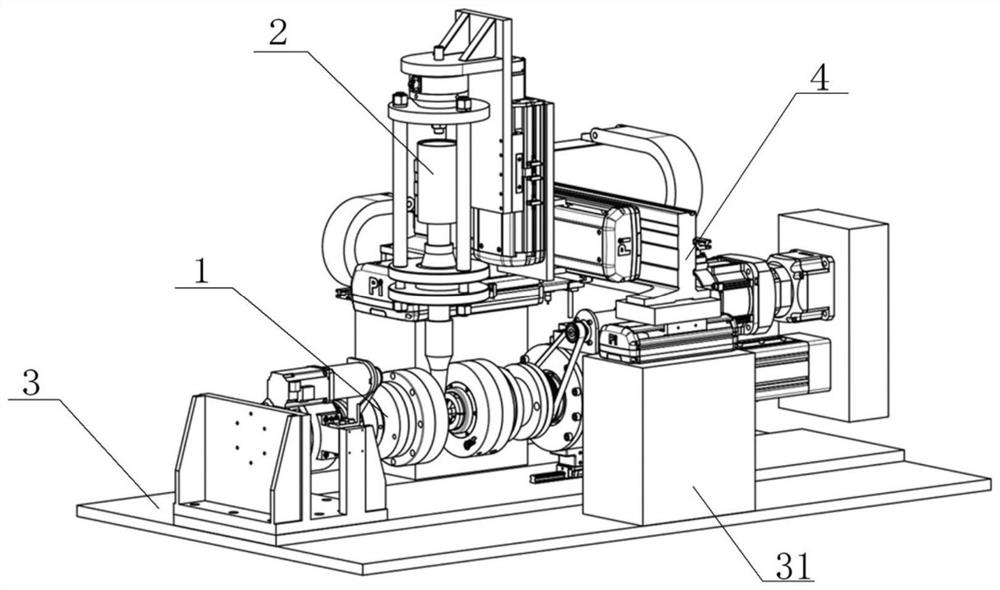

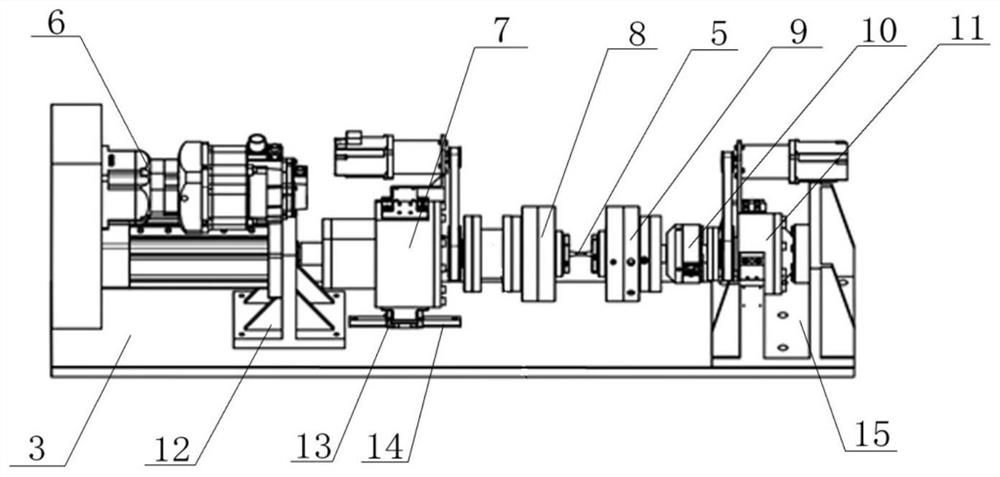

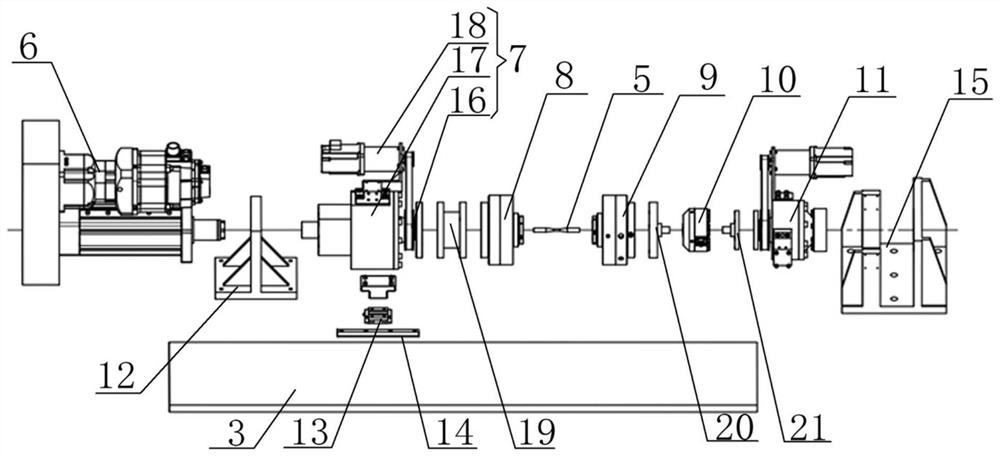

[0040] see Figure 1-5 Shown:

[0041] The present invention provides a material surface ultrasonic impact strengthening device, comprising a tensile loading module 1, an ultrasonic loading module 2, a base 3 and a three-axis slide table 4, the tensile loading module 1 is arranged longitudinally along the base 3, and its two ends are fixed On the base 3, the ultrasonic loading module 2 is connected with the three-axis slide 4, fixed on the base 3 through the three-axis slide 4, the ultrasonic loading module 2 is located above the tensile loading module 1; the test piece 5 is fixed on Tensile load module 1 on the clamp.

[0042]The tensile loading module 1 includes a servo electric cylinder 6, a first belt-driven rotating assembly 7, a first clamp 8, a second clamp 9 and a second belt-driven rotating assembly 11, and the servo electric cylinder 6 passes through the first The rib plate 12 is fixed on one end of the base 3, the servo electric cylinder 6 is connected with the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com