Amplitude self-adaptive rotating wheel

A self-adaptive, rotating wheel technology, applied in the direction of the fluid using vibration, can solve the problems of small volume, small adjustable range and small mass of the eccentric block, and achieve the effect of reducing resonance damage and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

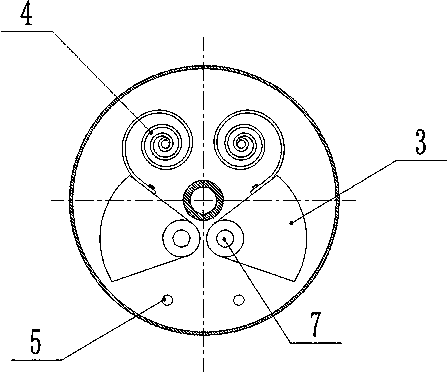

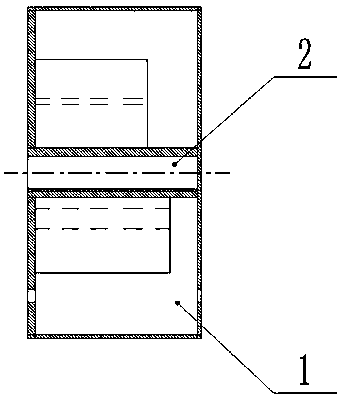

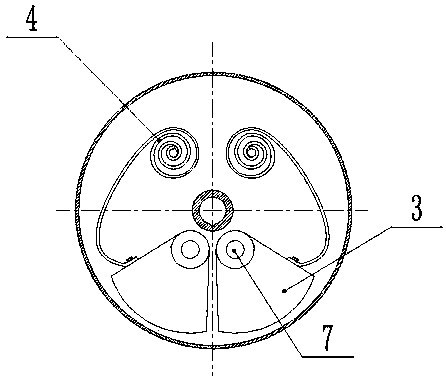

[0026] figure 1 and figure 2 As shown, the amplitude self-adaptive rotating wheel provided by the present invention includes a rotating disc 1, an eccentric block 3, a spring 4 and a pin shaft 6, one end of the spring 4 is fixed on the rotating disc 1, and the other end is connected to the eccentric block 3 , the eccentric block shaft 7 is fixed on the rotating disc 1, the center of the eccentric block shaft 7 does not coincide with the center of the rotating disc 1, the hole of the eccentric block 3 is loosely fitted with the eccentric block shaft 7, and there is a pin on the rotating disc 1 Shaft hole 5, fixed pin 6.

[0027] When the rotating wheel starts to rotate, the rotating disk 1 is driven to rotate by the rotating shaft 2, and the rotating disk 1 drives the eccentric block 3 to move, and the centrifugal force generated by the eccentric block 3 does not pass through its axis, and generates a rotational moment on the axis of the eccentric block. Make the eccentric b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com