Coating material mixing dispersion system capable of making coating material forward rotate and reverse rotate

A dispersion system, forward and reverse technology, applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve the problems of dead angle, rotating shaft cannot be raised and lowered, low efficiency, etc., to improve the degree of refinement, fast and uniform mixing, evenly mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

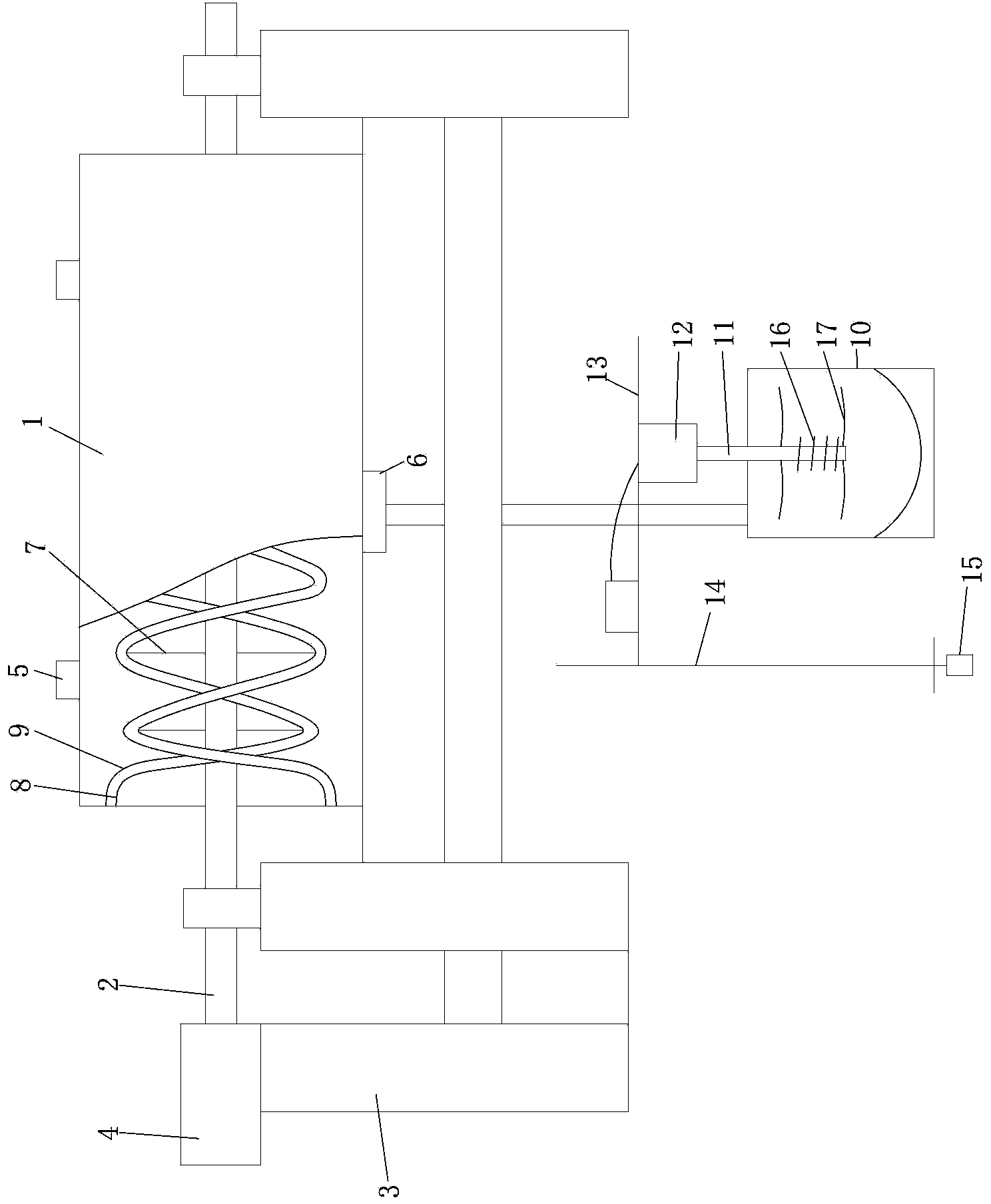

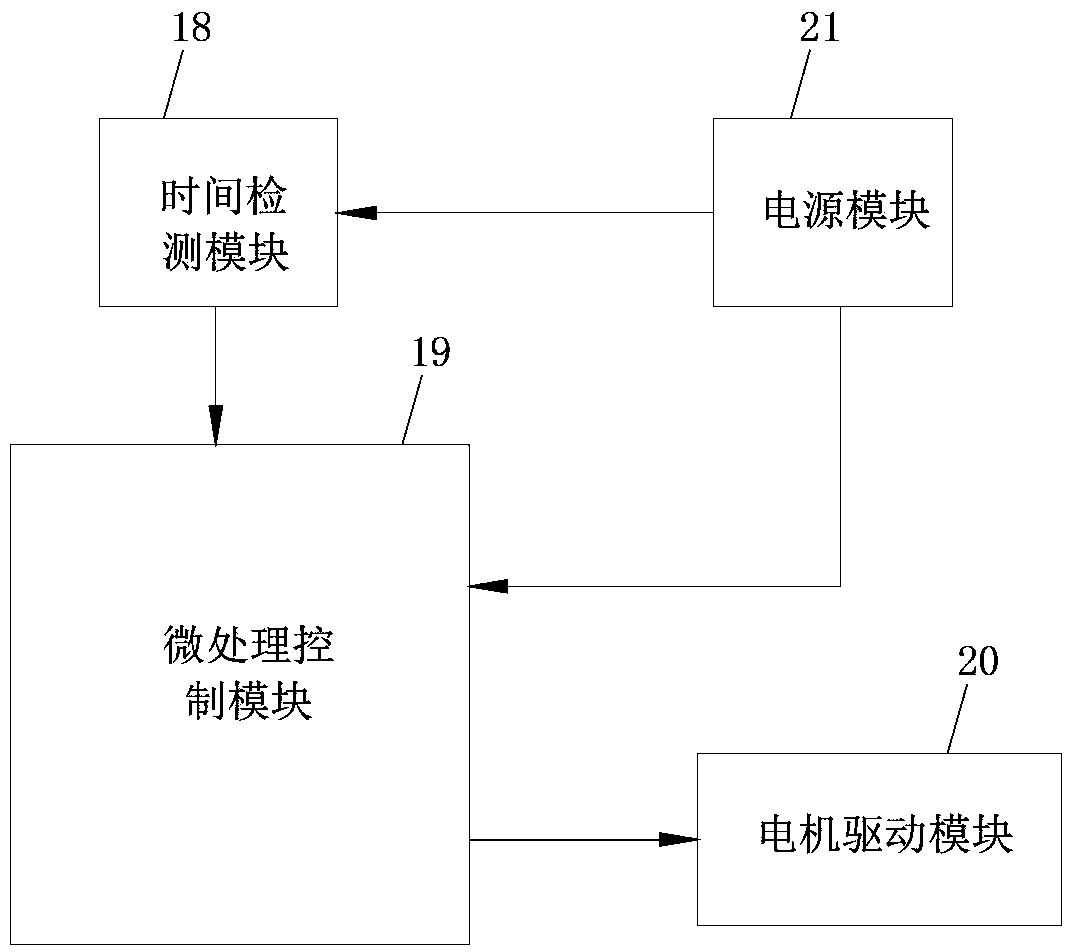

[0016] refer to figure 1 and figure 2 , a paint mixing and dispersing system with forward and reverse rotation of the present invention, comprising a mixing device, a dispersing device communicated with the mixing device through a pipeline, and a motor control device.

[0017] The mixing device includes a barrel 1, a rotating shaft 2, a bracket 3, and a driving motor 4. The barrel 1 is provided with a material inlet 5 and a mixed material output 6 . One end of the rotating shaft 2 passes through the barrel 1 , and the two ends of the rotating shaft 2 are supported on the bracket 3 through bearings 6 . The output end of the drive motor 4 is connected to the rotating shaft, and the drive motor 4 is a geared motor. A pair of spiral stirring bodies are symmetrically arranged on the shaft body of the rotating shaft 2 located in the barrel 1, and the spiral stirring bodies are fixedly connected with the support rod 7 fixed on the rotating shaft. The spiral stirring body is at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com